Method for synthesizing low-cost and super-absorbent resin from potato starch serving as raw material

A technology of potato starch and superabsorbent resin, which is applied in the field of synthesizing superabsorbent resin and simple preparation, to achieve the effect of increasing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

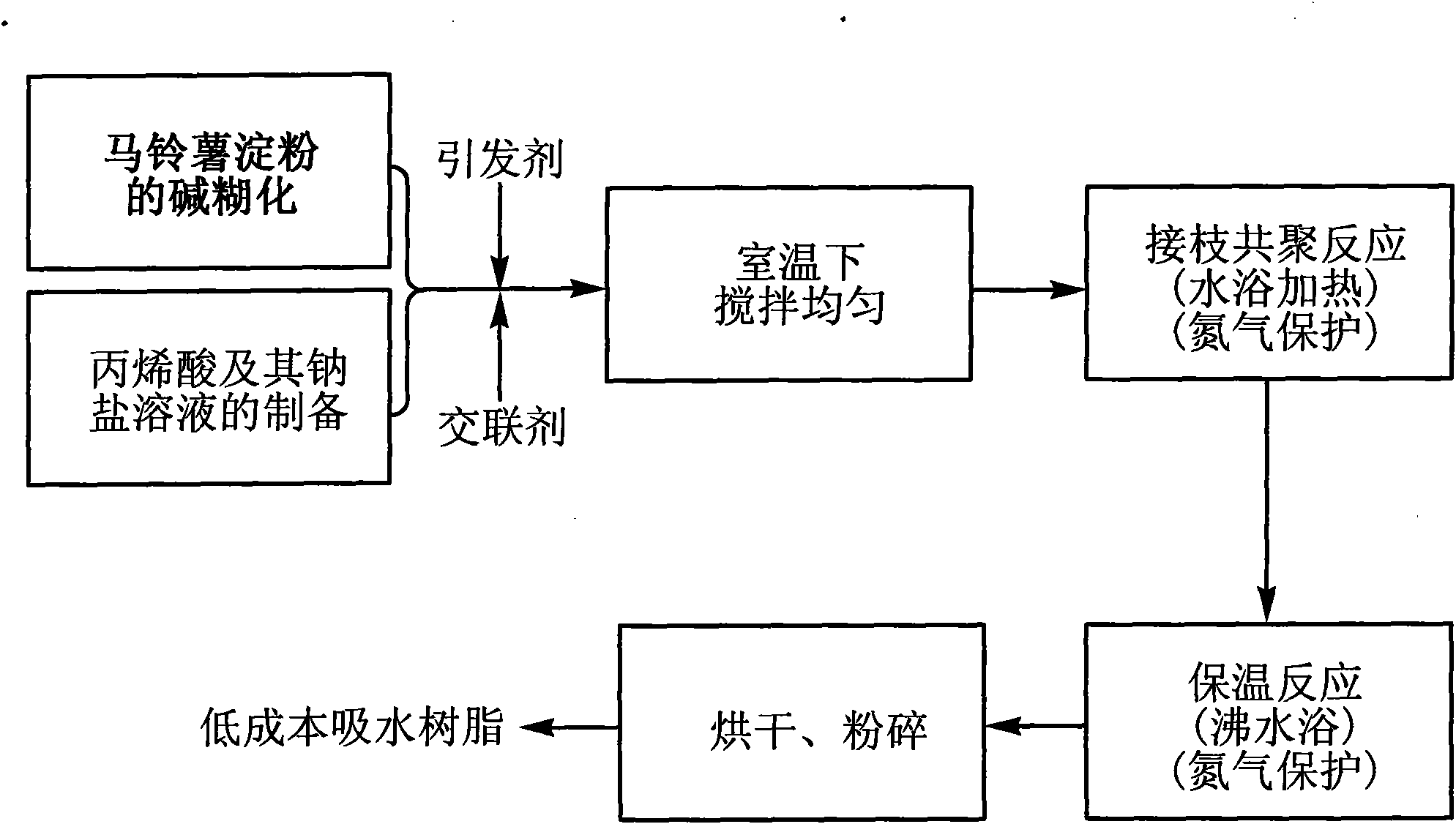

Method used

Image

Examples

Embodiment 1

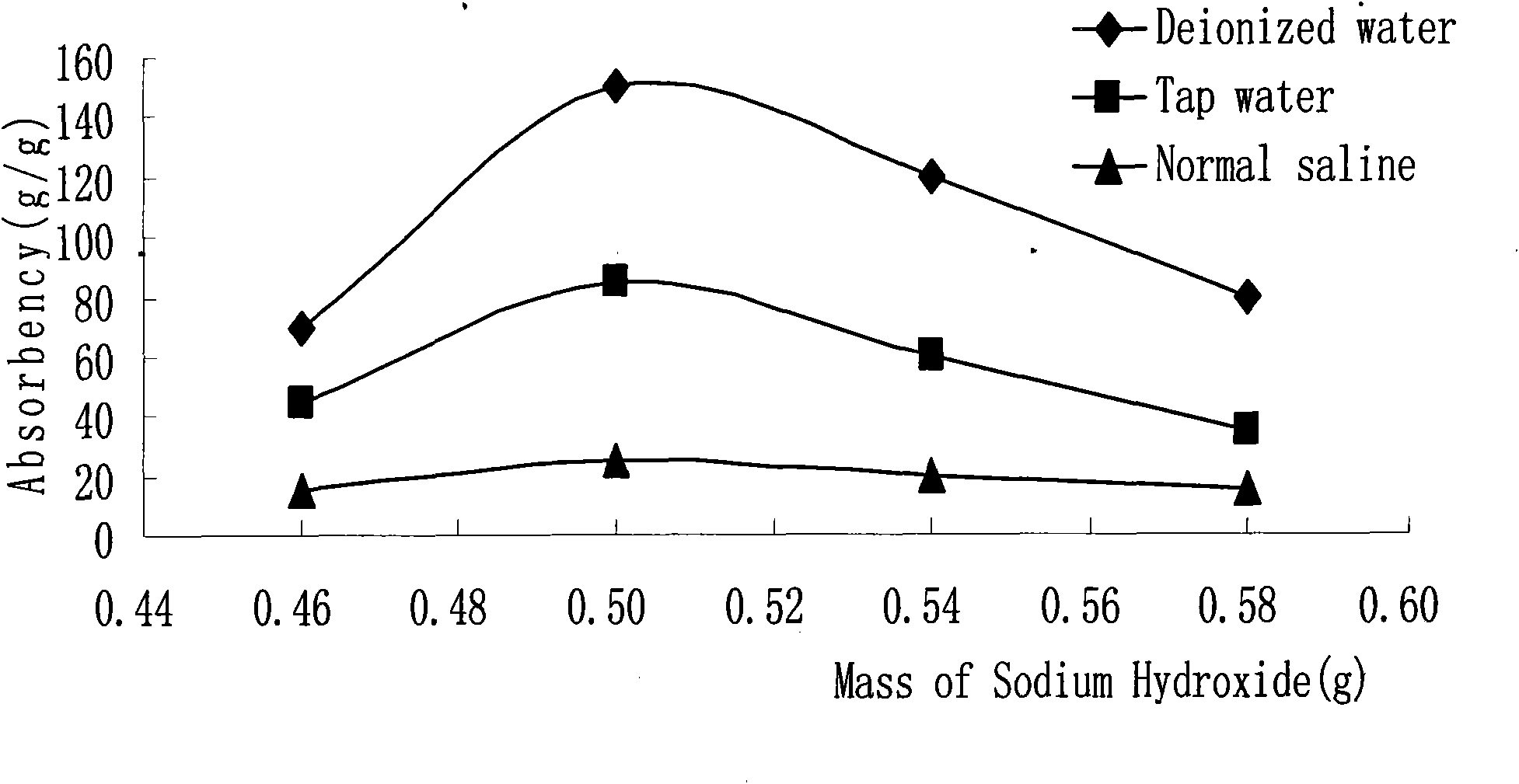

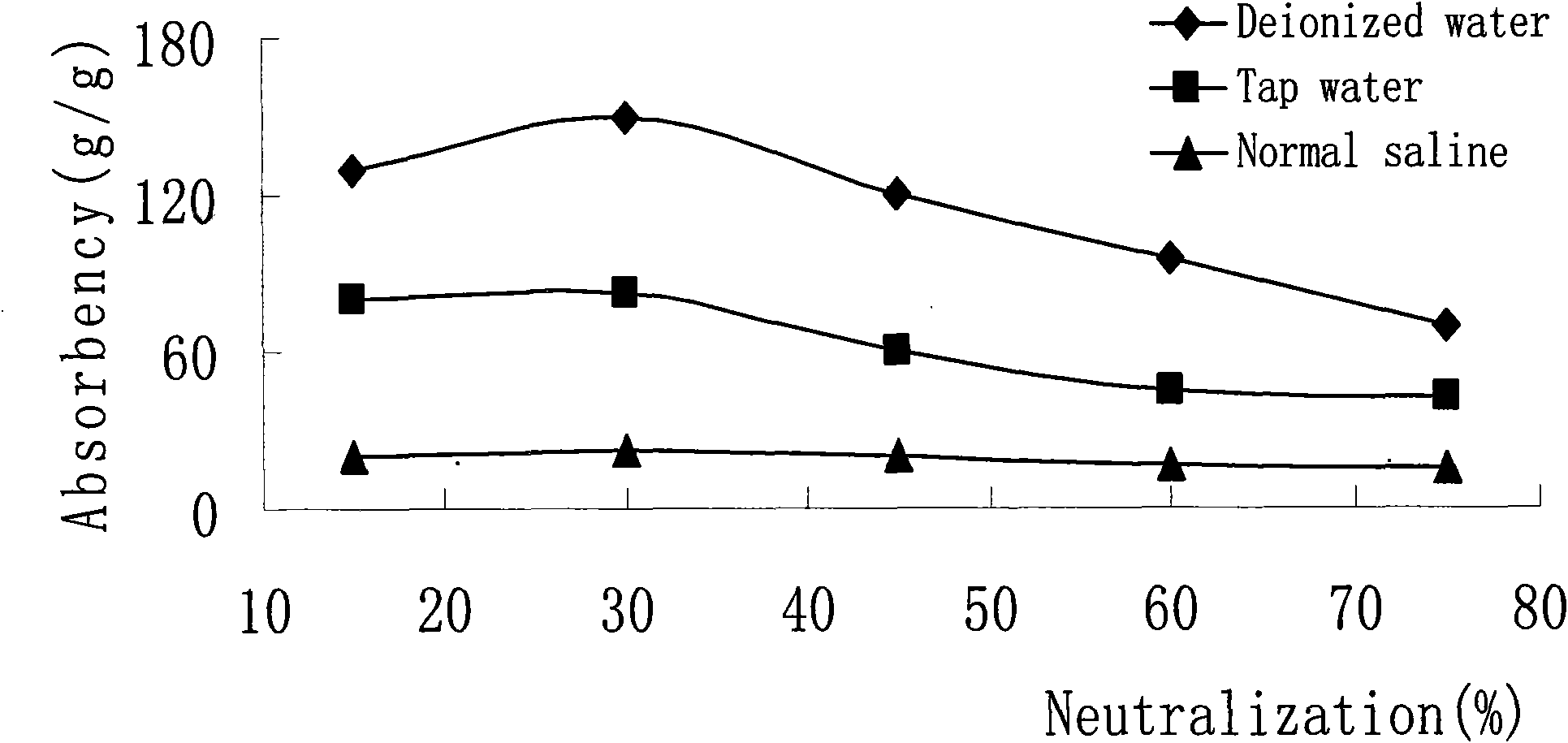

[0024] Embodiment 1: take by weighing 0.50g sodium hydroxide, be dissolved in 20.0ml deionized water, prepare the sodium hydroxide solution that molar concentration of hydroxide radical is 0.625mol / L; Take by weighing 2.5g sodium hydroxide, dissolve in 10.0ml In deionized water, under the conditions of cooling and stirring in an ice-water bath, neutralize 10.0 g (9.51 ml) of acrylic acid from which the polymerization inhibitor has been removed with sodium hydroxide solution to obtain acrylic acid and its sodium salt with a neutralization degree of acrylic acid of 45%. Solution: Weigh 10.0g of potato starch, mix it with 30.0ml of deionized water, stir for 0.5h, and use a sodium hydroxide solution with a hydroxide molar concentration of 0.625mol / L to 10-15 秒 / 滴 The drop-speed gelatinized potato starch milk; mix the prepared alkali-gelatinized potato starch with acrylic acid and its sodium salt solution, add 140mg potassium persulfate, 20mg N, N'-methylenebisacrylamide, and stir at...

Embodiment 2

[0025] Embodiment 2: experimental condition is the same as embodiment 1, and difference is to take by weighing 0.46g sodium hydroxide, be dissolved in 20.0ml deionized water, prepare the sodium hydroxide solution that molar concentration of hydroxide is 0.575mol / L, this The low-cost superabsorbent resin prepared in the example has a deionized water absorption capacity of 70 g / g, tap water capacity of 45 g / g, and physiological saline capacity of 15 g / g.

Embodiment 3

[0026] Embodiment 3: experimental condition is the same as embodiment 1, and difference is to take by weighing 0.54g sodium hydroxide, be dissolved in 20.0ml deionized water, prepare the sodium hydroxide solution that molar concentration of hydroxide is 0.675mol / L, this The low-cost superabsorbent resin prepared in the example has a deionized water absorption capacity of 120 g / g, tap water capacity of 60 g / g, and physiological saline capacity of 20 g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com