A chemical looping combustion oxygen carrier and its application method

A technology of chemical chain combustion and application method is applied in the field of sintering and returning ore as an oxygen carrier for chemical chain combustion, which can solve problems such as inability to enter the furnace, and achieve the effects of low price, broad application prospects and abundant inventory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

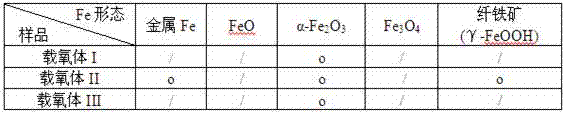

[0017] 1) Screen the sintered ore to obtain an oxygen carrier with a particle size of 10 μm-500 μm, which is designated as oxygen carrier I, and its active component is α-Fe 2 o 3 , its mass percentage content is 75%; the mass percentage content of inert components is CaO: 10%, Al 2 o 3 : 2% and SiO 2 : 10%, the rest are impurities;

[0018] 2) Spread 300 mg of the oxygen carrier I obtained in step 1) on the bottom of the fixed-bed reactor (quartz tube). In a nitrogen atmosphere, the sample was heated to 800 °C; then, the nitrogen was switched to a reducing atmosphere (10% CH 4 ,90%N 2 ) carry out a reduction experiment on the sample, and the constant temperature lasts for 20 minutes; then stop the heat preservation, switch the reducing gas to nitrogen, and cool the sample under a nitrogen environment to obtain the oxygen carrier II;

[0019] 3) Spread 300 mg of the oxygen carrier I obtained in step 1) on the bottom of the fixed-bed reactor (quartz tube). In a nitrogen ...

Embodiment 2

[0026] 1) Screen the sintered ore to obtain an oxygen carrier with a particle size of 10 μm-500 μm, which is designated as oxygen carrier I, and its active component is α-Fe 2 o 3 , its mass percentage content is 80%; the mass percentage content of inert components is CaO: 10%, Al 2 o 3 : 2% and SiO 2 : 8%, the rest are impurities;

[0027] 2) Spread 300 mg of the oxygen carrier I obtained in step 1) on the bottom of the fixed-bed reactor (quartz tube). In a nitrogen atmosphere, the sample was heated to 750 °C; then, the nitrogen was switched to a reducing atmosphere (10% CH 4 ,90%N 2 ) carry out the reduction experiment on the sample, and the constant temperature lasts for 20 minutes; then the reducing gas is switched to nitrogen, and the quartz tube is purged for 5 minutes to remove the remaining reducing gas; then, the gas is switched to air, and the reduced sample is Oxidation, constant temperature ventilation for 20 minutes; then switch to nitrogen, purging for 5 mi...

Embodiment 3

[0036] 1) Sieve the sintered ore to obtain an oxygen carrier with a particle size of 10 μm-500 μm, which is designated as oxygen carrier I;

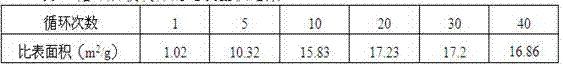

[0037] 2) Spread 300 mg of the oxygen carrier I obtained in step 1) on the bottom of the fixed-bed reactor (quartz tube). In a nitrogen atmosphere, the samples were heated to 700, 750, 800, 850, and 900 °C; then, the nitrogen was switched to a reducing atmosphere (10% CH 4 ,90%N 2 ) carry out the reduction experiment on the sample, and the constant temperature lasts for 20 minutes; then the reducing gas is switched to nitrogen, and the quartz tube is purged for 5 minutes to remove the remaining reducing gas; then, the gas is switched to air, and the reduced sample is Oxidation, constant temperature ventilation for 20 minutes; then switch to nitrogen, purging for 5 minutes, then switch to reducing gas, a new cycle begins; after 10 cycles respectively, stop the heat preservation, switch the reducing gas to nitrogen, and make the sample C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com