Preparation method of EU-1/MOR (mordenite) co-crystallized molecular sieve

A symbiotic molecular sieve, EU-1 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increasing cost, increasing operation steps, and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

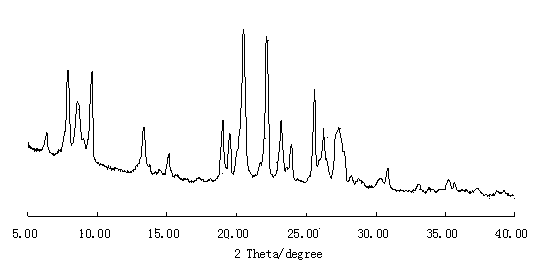

[0032] Take 11 g of sodium hydroxide and 8.2 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 83 g of white carbon black slowly and stir vigorously for 30 min. Then 60 g of hexamethonium bromide was added. Then put it into a closed reactor and crystallize in an oven at 195°C for 72h. The obtained product was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and then placed in a muffle furnace for 6 hours at 550°C. The obtained sample was a sodium type EU-1 molecular sieve with a silicon-aluminum molar ratio of 35.

[0033] Take 7 g of sodium hydroxide and 2.2 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 33 g of white carbon black slowly and stir vigorously for 30 min. Then 3 g of EU-1 molecular sieve seeds were added and stirred vigorously for 30 min. Then it was aged at room temperature for 4 hours, and then put ...

Embodiment 2

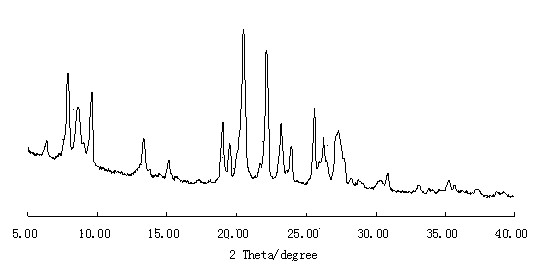

[0035] Take 11 g of sodium hydroxide and 8.2 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 83 g of white carbon black slowly and stir vigorously for 30 min. Then 60 g of hexamethonium bromide was added. Then put it into a closed reactor and crystallize in an oven at 195°C for 72h. The obtained product was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and then placed in a muffle furnace for 6 hours at 550°C. The obtained sample was a sodium type EU-1 molecular sieve with a silicon-aluminum molar ratio of 35.

[0036] Take 7.5 g of sodium hydroxide and 1.8 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 30 g of white carbon black slowly and stir vigorously for 30 min. Then 3.8 g of EU-1 molecular sieve seed crystals were added and stirred vigorously for 20 min. Then it was aged at room temperature for 5 hours, t...

Embodiment 3

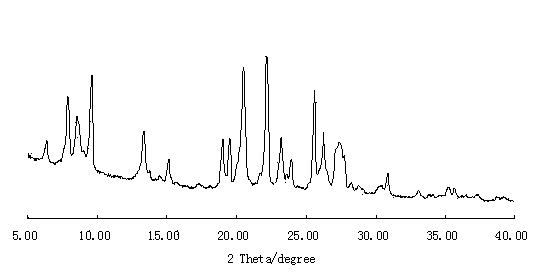

[0038] Take 11 g of sodium hydroxide and 8.2 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 83 g of white carbon black slowly and stir vigorously for 30 min. Then 60 g of hexamethonium bromide was added. Then put it into a closed reactor and crystallize in an oven at 195°C for 72h. The obtained product was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and then placed in a muffle furnace for 6 hours at 550°C. The obtained sample was a sodium type EU-1 molecular sieve with a silicon-aluminum molar ratio of 35.

[0039] Take 6.5 g of sodium hydroxide and 2.0 g of sodium aluminate in 500 mL of distilled water, and stir vigorously until they are completely dissolved. Add 35 g of white carbon black slowly and stir vigorously for 40 min. Then 4 g of EU-1 molecular sieve seeds were added and stirred vigorously for 30 min. Then it was aged at room temperature for 7 hours, then put in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com