Synchronous denitrification and dephosphorization adsorbent as well as preparation method and application thereof

A simultaneous denitrification and dephosphorization, adsorbent technology, applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of wide sources, low price and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

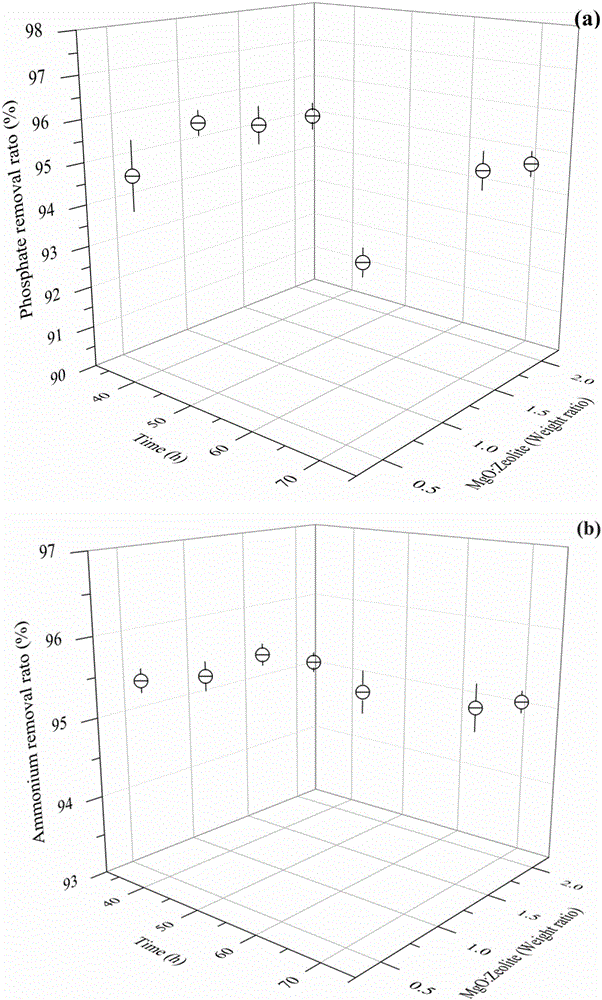

[0040] Take simulated wastewater with a phosphate concentration of 50mg / L.

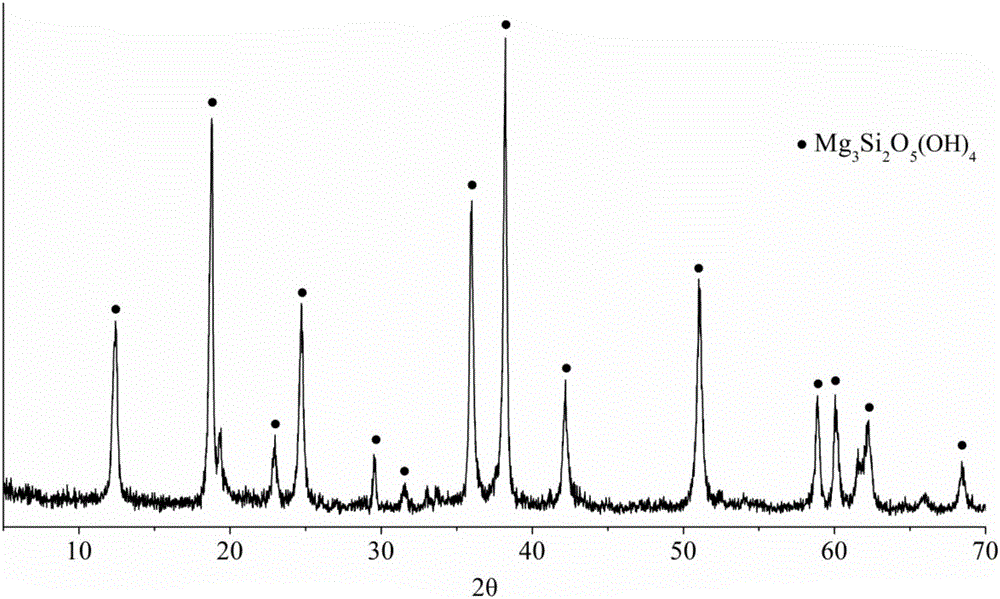

[0041] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment comprises the calcined product of magnesite powder and zeolite powder, and its preparation steps are:

[0042] (1) Crushing the magnesite ore and passing through a 100-mesh sieve, taking the under-sieve and calcining at 600°C for 4 hours to obtain a calcined product of magnesite powder; crushing and grinding the zeolite, and passing through a 100-mesh sieve to obtain zeolite powder;

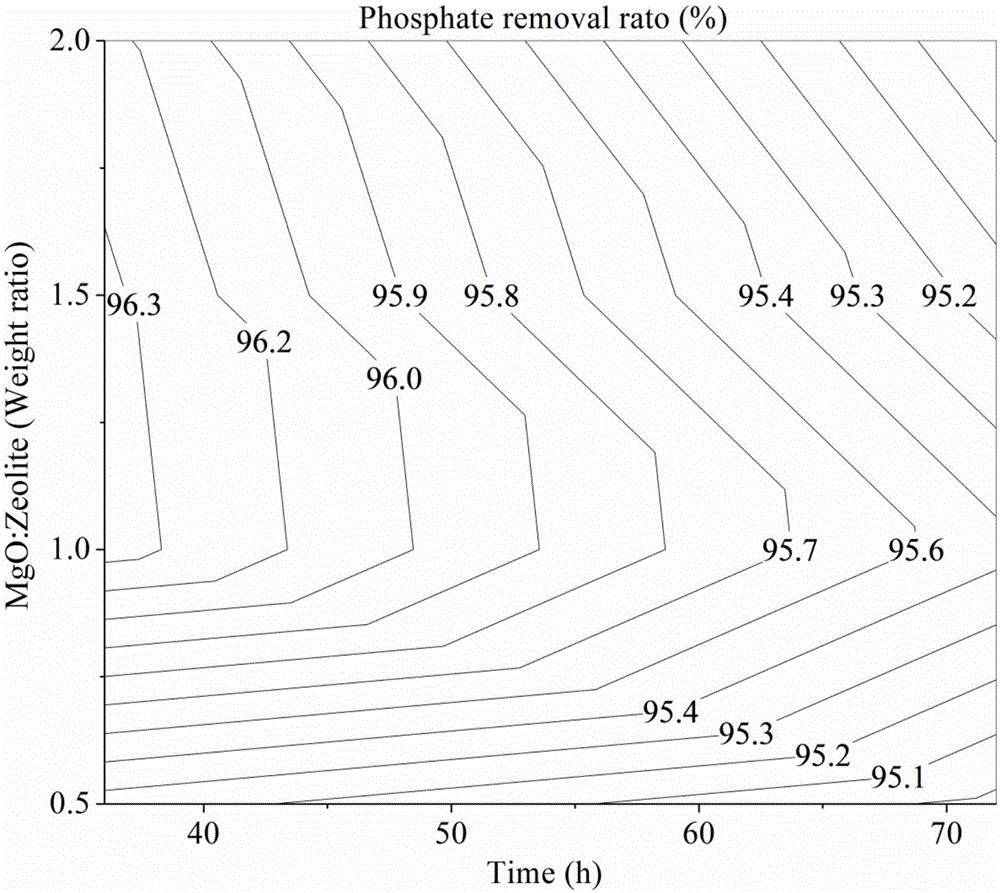

[0043] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 0.5-2:1. After mixing in water, the hydrothermal method is synthesized at 200°C for 36-72 hours, then cooled, and centrifuged to obtain the synthesized product. Simultaneous nitrogen and phosphorus removal adsorbent.

[0044] The application of a kind of simultaneous denitrification and dephosphorization adsorbent in this embodiment, the st...

Embodiment 2

[0049] Application of a simultaneous denitrification and phosphorus removal adsorbent in this embodiment in domestic sewage treatment:

[0050] Take simulated domestic sewage, the concentration of phosphate is 50mg / L, and the concentration of ammonia nitrogen is 20mg / L.

[0051] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment and its preparation method and application, its steps are:

[0052] (1) crush the magnesite ore and pass through a 100-mesh sieve, take the under-sieve and calcinate at 1000°C for 1 hour to obtain a calcined product; crush and grind the zeolite, and pass through a 100-mesh sieve to obtain zeolite powder;

[0053] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 0.5 to 2:1. After mixing, ball milling is carried out first. The ball milling time is 30min, and the speed is 300r / min; , synthesized by hydrothermal method for 36-72 hours, then cooled, centrifuged and filtered to obtain the ...

Embodiment 3

[0060] The application of a simultaneous denitrification and phosphorus removal adsorbent in this embodiment in the treatment of chemical wastewater:

[0061] Take the simulated chemical wastewater, the concentration of phosphate is 50mg / L, and the concentration of ammonia nitrogen is 20mg / L.

[0062] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment and its preparation method and application, its steps are:

[0063] (1) crush the magnesite ore and pass through a 100-mesh sieve, take the under-sieve and calcinate at 800°C for 3 hours to obtain a calcined product; crush and grind the zeolite, and pass through a 100-mesh sieve to obtain zeolite powder;

[0064] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 1:1, and ball milling is carried out after mixing, the ball milling time is 90min, and the rotating speed is 100r / min; Synthesize by thermal method for 50h, then cool down, and centrifuge to filter to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com