Preparation method of 4-methylpyrazole

A technology of methylpyrazole and hydrazine sulfate, applied in the direction of organic chemistry, can solve the problems of insufficient purity, many impurities, black color, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

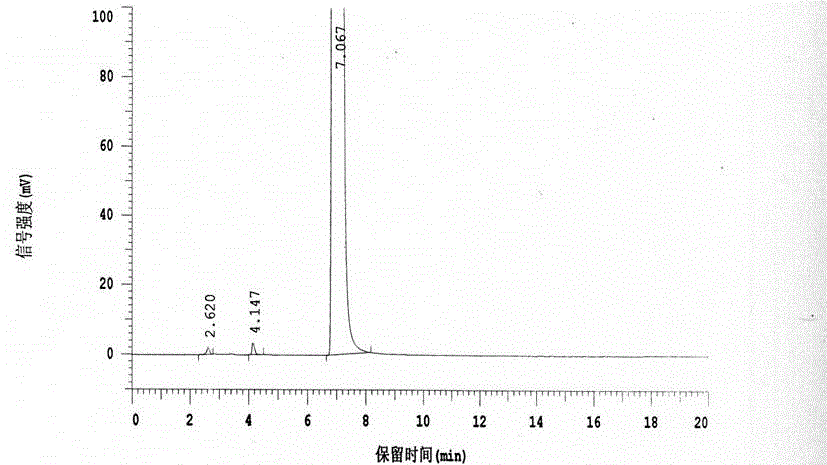

Embodiment 1

[0032] The preparation method of 4-methylpyrazole of the present invention, the detailed steps of this preparation method are as follows:

[0033] a, the preparation of hydrazine sulfate:

[0034] Concentrated sulfuric acid (98% by mass) and hydrazine hydrate (80% by mass) are used as raw materials, and the two raw materials are weighed according to the mass ratio between concentrated sulfuric acid and hydrazine hydrate of 1:1.0 , first add the weighed concentrated sulfuric acid into the reaction vessel, and stir, put the reaction vessel with the concentrated sulfuric acid into the low-temperature reactor to cool down, so that the temperature in the reactor drops to -10°C, and slowly add Hydrazine hydrate, hydrazine hydrate was added dropwise for 1 hour, the temperature was controlled at 0°C and the reaction was continuously stirred for 2 hours, suction filtration was performed after the reaction, the obtained filter cake was washed with absolute ethanol, and the washed filter...

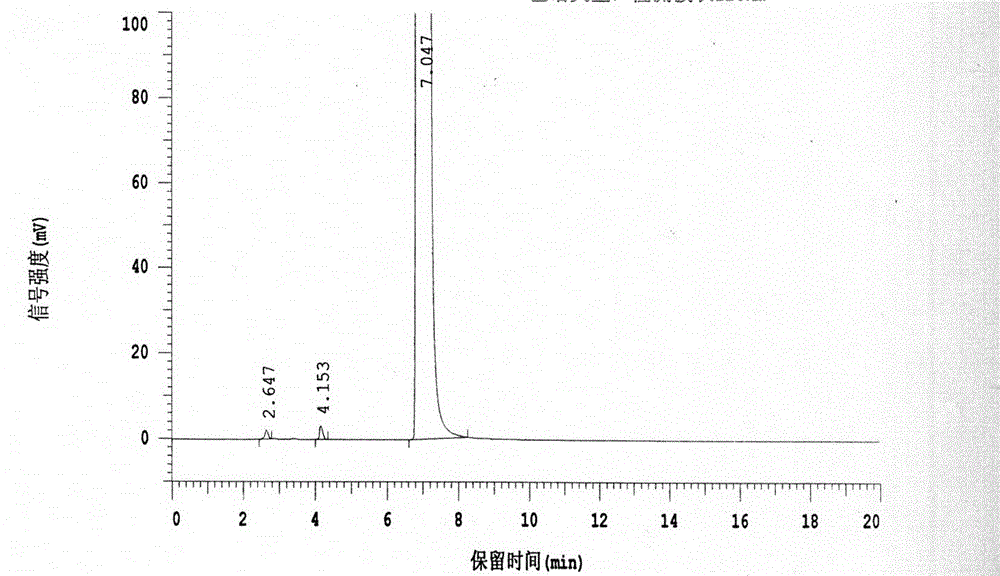

Embodiment 2

[0044] The preparation method of 4-methylpyrazole of the present invention, the detailed steps of this preparation method are as follows:

[0045] a, the preparation of hydrazine sulfate:

[0046]Concentrated sulfuric acid (98% by mass) and hydrazine hydrate (80% by mass) are used as raw materials, and the two raw materials are weighed according to the mass ratio between concentrated sulfuric acid and hydrazine hydrate of 1:1.3 , first add the weighed concentrated sulfuric acid into the reaction vessel, and stir, put the reaction vessel with the concentrated sulfuric acid into the low-temperature reactor to cool down, so that the temperature in the reactor drops to -5°C, and slowly add Hydrazine hydrate, hydrazine hydrate was added dropwise for 1.5 hours, the temperature was controlled at 5°C and the reaction was continuously stirred for 2.2 hours, suction filtration was performed after the reaction, the obtained filter cake was washed with absolute ethanol, and the washed fil...

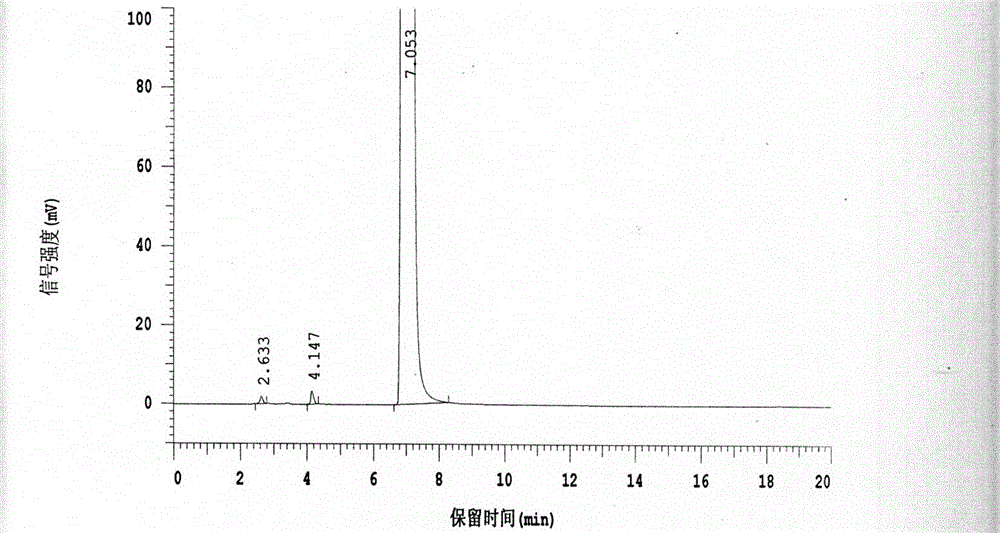

Embodiment 3

[0056] The preparation method of 4-methylpyrazole of the present invention, the detailed steps of this preparation method are as follows:

[0057] a, the preparation of hydrazine sulfate:

[0058] Concentrated sulfuric acid (98% by mass) and hydrazine hydrate (80% by mass) are used as raw materials, and the two raw materials are weighed according to the mass ratio between concentrated sulfuric acid and hydrazine hydrate of 1:1.5 , first add the weighed concentrated sulfuric acid into the reaction vessel, and stir, put the reaction vessel with the concentrated sulfuric acid into the low-temperature reactor to cool down, so that the temperature in the reactor drops to 0°C, and slowly add the hydration Hydrazine, hydrazine hydrate was added dropwise for 2 hours, the temperature was controlled at 10°C and the reaction was continuously stirred for 2.5 hours, suction filtration was performed after the reaction, the obtained filter cake was washed with absolute ethanol, and the washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com