Surface coating method of transmission mechanism

A transmission mechanism and surface coating technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of broken bond ability, decreased wear resistance of coated drive shaft 12, and amorphous DLC film 123 Reduce surface hardness and other problems, achieve high surface hardness and avoid tempering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Due to the surface coating method provided by the invention, various transmission mechanisms (such as: bearings, transmission shafts, chains, spur gears, helical gears, bevel gears, cams, racks and transmission screws, etc.) can be widely coated. Various coating transmission mechanisms are manufactured, and the combinations thereof are too numerous to enumerate, so no more details are given here, and only one preferred embodiment is listed for specific illustration.

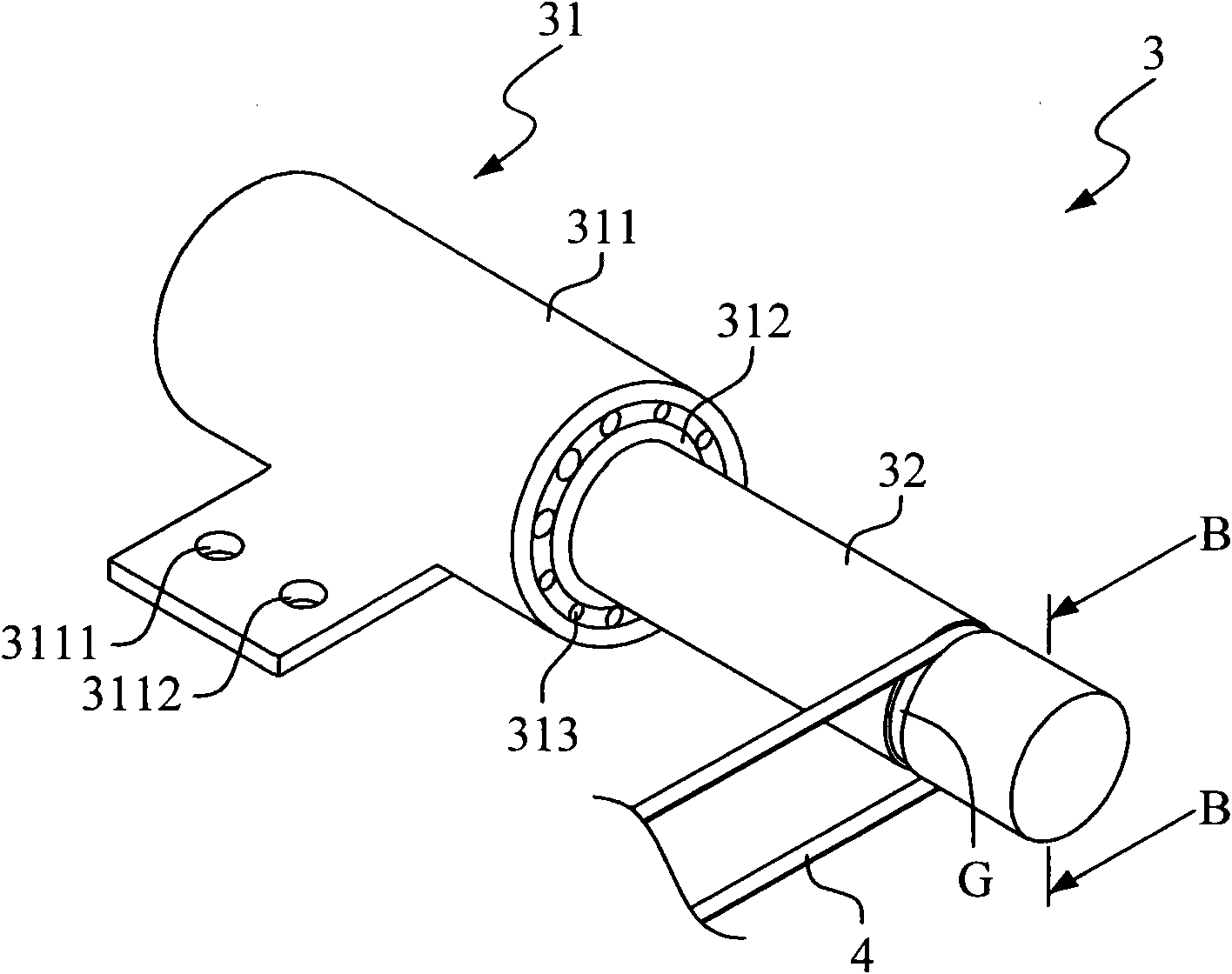

[0075] see image 3 , which shows a schematic diagram of a preferred embodiment of the present invention applicable to a transmission assembly. As shown in the figure, a transmission assembly 3 includes a coating bearing 31 and a coating transmission shaft 32 , and both the coating bearing 31 and the coating transmission shaft 32 can be regarded as a coating transmission mechanism.

[0076] The coated bearing 31 includes a fixed outer shaft 311 , a rotatable inner shaft 312 and a plurality of rollers 313 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com