Hydrogenation method of hydroxyl terminated butyl nitrile (HTBN)

A liquid nitrile and hydroxyl-terminated technology, which is applied in the field of hydrogenation of new polymer-hydroxyl-terminated liquid nitrile, can solve problems such as poisoning and inability to realize hydrogenation of hydroxyl-terminated liquid nitrile rubber, and achieve simple process and hydrogenation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

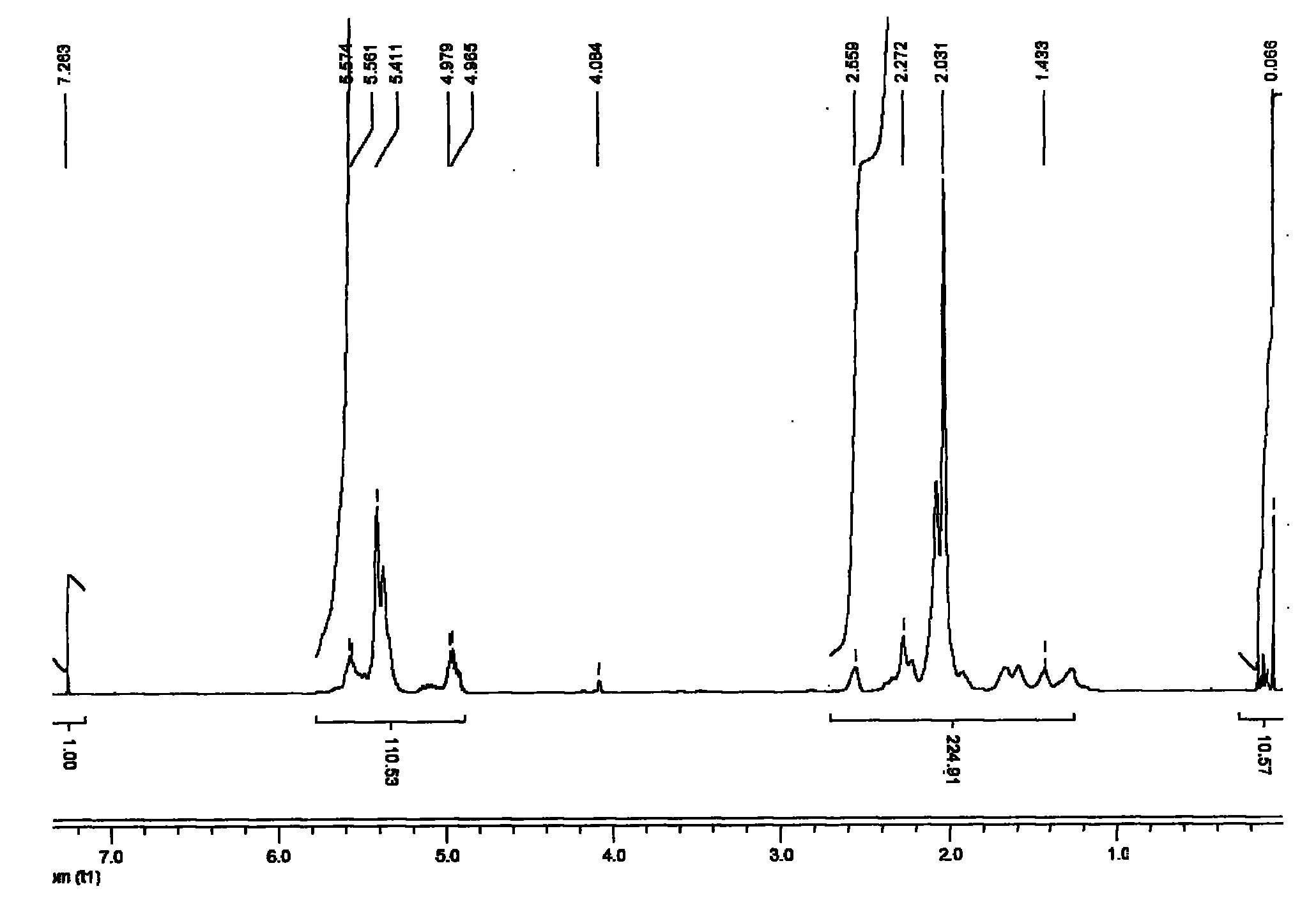

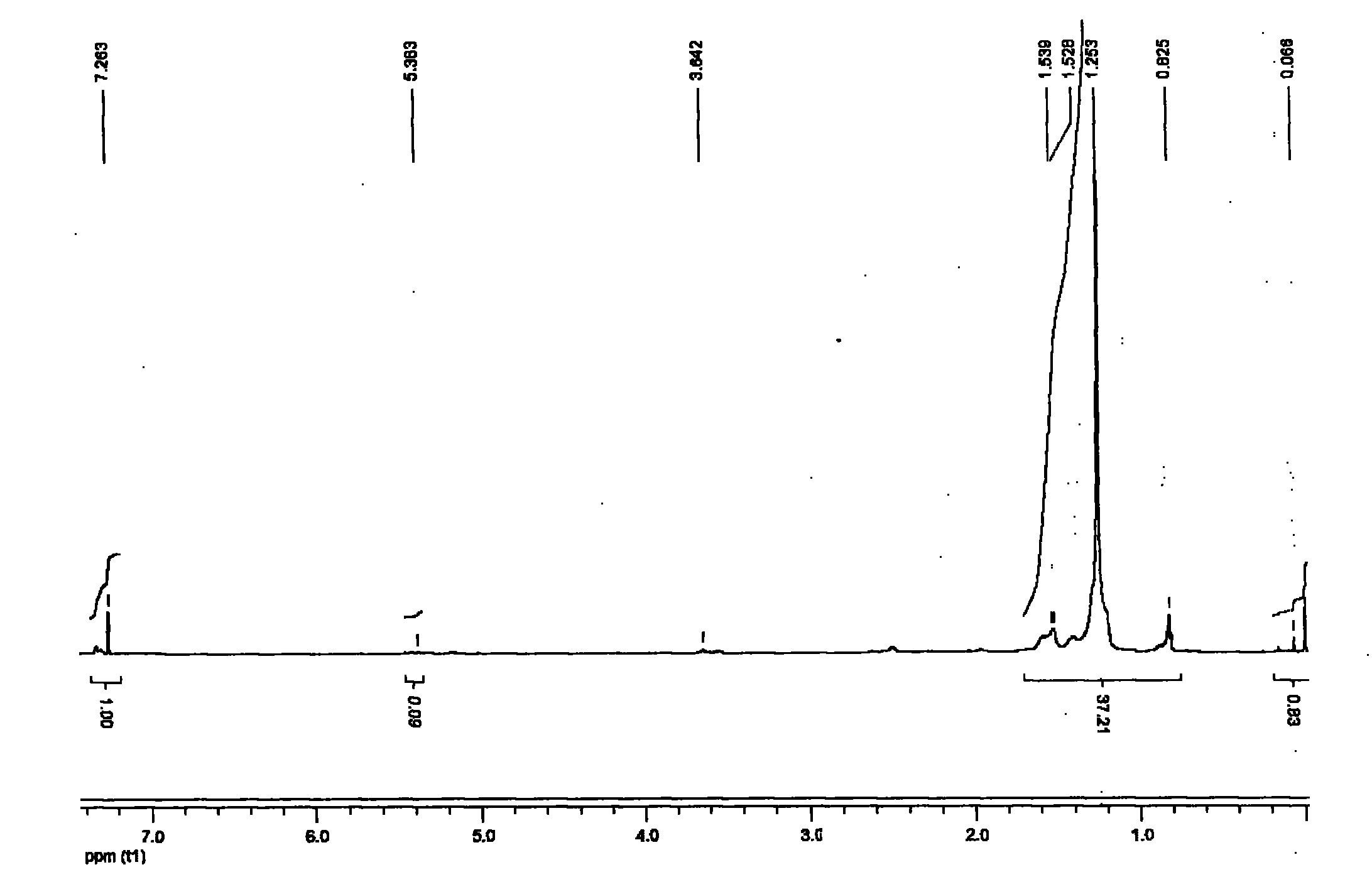

[0022] According to the general procedure of above-mentioned hydrogenation, 7.5g (molecular weight is 7160, and acrylonitrile mass percent content is 20%) of end-capped hydroxyl liquid nitrile copolymer is dissolved in the xylene of 50ml, adds in the hydrogenation reactor of 100ml, in Add 0.06g of triphenylphosphine rhodium chloride and 0.48g of triphenylphosphine into the reaction kettle under a nitrogen atmosphere, control the temperature at 100°C, the pressure of hydrogen at 1MPa, and the reaction time of 8 hours. The hydrogenation results are shown in Table 1 .

Embodiment 2

[0028] Change the amount of the capped hydroxyl liquid butyronitrile into 2.5g, 5g, and 10g in Example 1, and others are the same as Example 1. The results are shown in Table 2.

[0029] Table 2

[0030] The mass of capped hydroxyl liquid butyronitrile (g)

Embodiment 3

[0032] Change the amount of triphenylphosphorus rhodium chloride into 0.045g, 0.09g, and 0.12g in Example 1, and others are the same as Example 1. The results are shown in Table 3.

[0033] table 3

[0034] The mass of triphenylphosphine rhodium chloride (g)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com