Preparation method of soft magnetic composite material

A kind of soft magnetic composite material, soft magnetic powder technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The steps of the soft magnetic composite material preparation method are as follows:

[0020] 1) Preparation of sol: Fe 3+ The salt is dissolved in ethylene glycol solution to make Fe 3+ The solubility is 2mol / L, heated to 30~50 o C, stirring for 1~3h to form a sol;

[0021] 2) Coating of metal soft magnetic alloy: Add soft magnetic powder into the sol, stir and mix thoroughly, heat to 60~90 o C, keep warm until the gel is obtained; age the gel for 1~4h, then heat it at 80~120 o Dry under C conditions for 3~5h, and the dry gel after drying is at 200~400 o Anneal in an inert gas of C for 3~5h; obtain coated soft magnetic powder, the amount of soft magnetic powder makes the mass percentage of soft magnetic powder in the final product be 70~99%, Fe 3 o 4 The mass percentage in the product is 1~30%;

[0022] 3) Add binder: Take the coated soft magnetic powder with a mass fraction of 0.5-2.5% of the binder and pour it into the soft magnetic powder treated in step 2). ...

Embodiment 1

[0028] 0.02mol Fe(NO 3 ) 3 Dissolve in 10ml of ethylene glycol, heat to 40 o C and stir for 2h, then add 60g iron powder, heat to 80 o C and stirred until a gel was obtained, and the obtained gel was aged for 2h at 120 o Dry under C condition for 4h, the xerogel obtained at 400 o C temperature under the condition of nitrogen protection under heat treatment for 4h.

[0029] The iron powder obtained is added in the mixed solution of 2wt% epoxy resin and 10wt% acetone, at 80 o Stir under the condition of C until the powder is dry, then add 0.5wt% barium stearate, and press it into a dense ring shape under the condition of 800MPa, for the ring sample at 400 o Annealed under C condition for 1h to make a soft magnetic composite material.

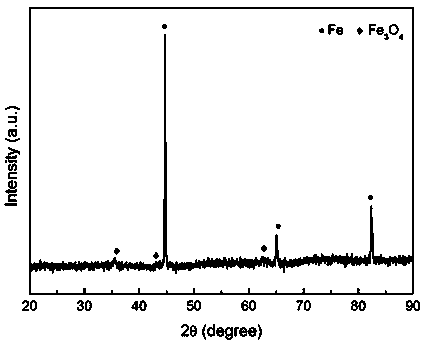

[0030] After testing, the magnetization of the soft magnetic alloy is 1.6T, and the magnetic permeability is 80, figure 1 For iron powder surface generation Fe in embodiment 1 3 o 4 X-ray (XRD) spectrum lines of core-shell composite soft ...

Embodiment 2

[0032] 0.2mol FeCl 3 Dissolve in 100ml of ethylene glycol, heat to 30 o C and stirred for 3h, then added 150g sendust powder, heated to 60 o C and stirred until a gel was obtained, and the obtained gel was aged for 1 h at 80 o C condition is dried 3h, and the xerogel obtained is at 200 o C temperature under the condition of argon protection under heat treatment for 5h.

[0033] Add 1.5wt% silicone resin, 1.0wt% SiO to the obtained alloy powder 2 In a mixed solution with 10wt% acetone, at 80 oStir under C conditions until the powder is dry, then add 0.25wt% zinc stearate and 0.25wt% barium stearate, and press it into a dense ring shape under the condition of 2000MPa. o Annealed under C condition for 2h to make a soft magnetic composite material.

[0034] After testing, the magnetization of the soft magnetic alloy is 1.2T, and the magnetic permeability is 92.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com