Low-loss FeSiAl/MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity and preparation method of low-loss FeSiAl/MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity

A soft magnetic composite, ferrite technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of high loss, limited application in high frequency fields, easy to generate heat, etc., to reduce power loss, The effect of avoiding the decrease of saturation magnetization and permeability and increasing the resistivity of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Concretely, the preparation method of the FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic permeability and low loss of the present invention, the steps include:

[0029] S1. Powder screening: Take crushed FeSiAl powder, its composition and the mass percentage of each component are: Si: 8%-13%, Al: 4%-7%, and the rest is Fe. Passing the crushed FeSiAl powder through a sieve to obtain FeSiAl powder with a particle size not greater than 75 microns;

[0030] S2. Powder annealing: put FeSiAl magnetic powder into the atmosphere furnace, introduce reducing gas, control the temperature at 600-800°C, and heat-treat for 0.5-5h; the reducing gas is one or both of hydrogen and hydrogen-argon mixed gas. a mixture of species;

[0031] S3. Phosphoric acid phosphating: add the annealed FeSiAl magnetic powder into the phosphoric acid solution for phosphating and drying to obtain phosphating FeSiAl magnetic powder; wherein, in the phosphoric acid so...

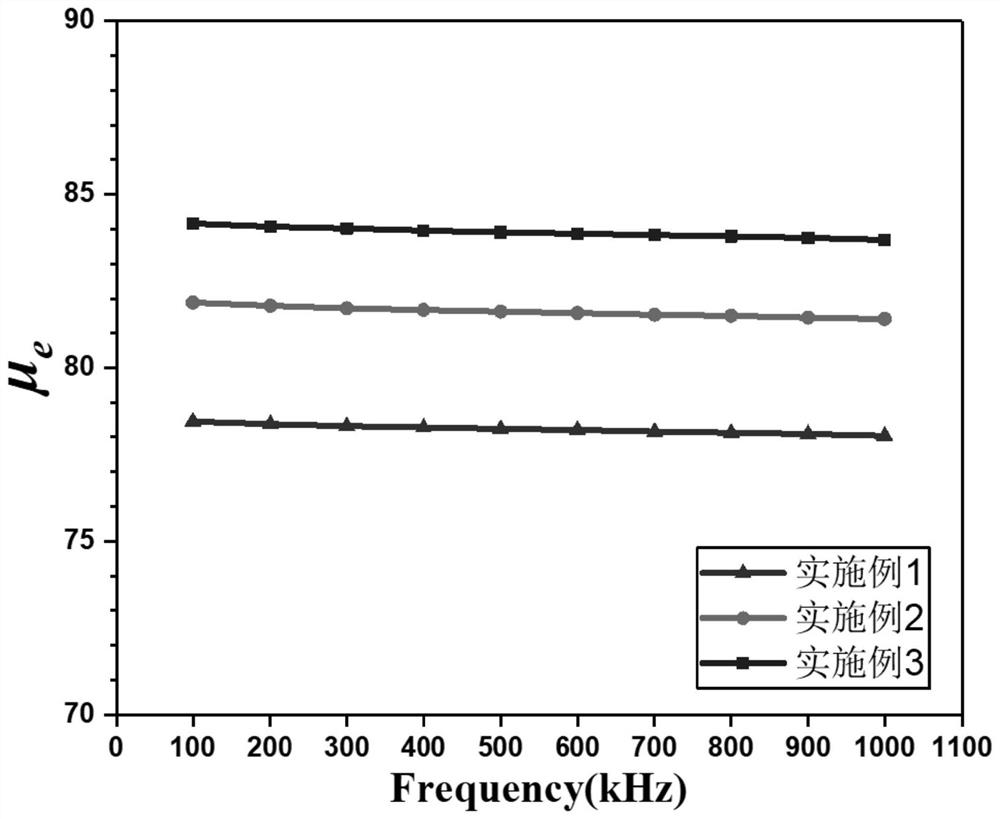

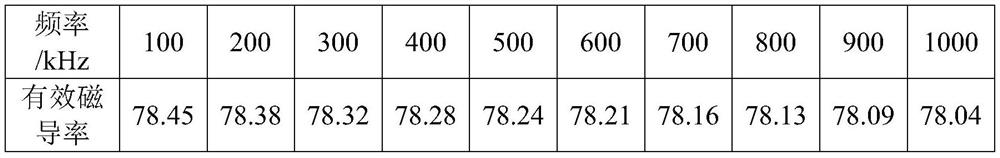

Embodiment 1

[0040] The preparation method of the stable magnetic permeability and low loss FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core in this embodiment includes the following steps:

[0041] 1. Take crushed FeSiAl powder, the composition of which is Si: 8%, Al: 7%, and the rest is Fe. Pass the crushed powder through a sieve, and select the powder under a 200 mesh sieve (<75 microns);

[0042] 2. Put the FeSiAl magnetic powder into the atmosphere furnace, pass in hydrogen, control the temperature at 600°C, and anneal for 5 hours;

[0043] 3. Adding the annealed FeSiAl magnetic powder to an acetone phosphate solution with a solute mass percentage of 0.1wt.% for phosphating and drying to obtain phosphating FeSiAl magnetic powder;

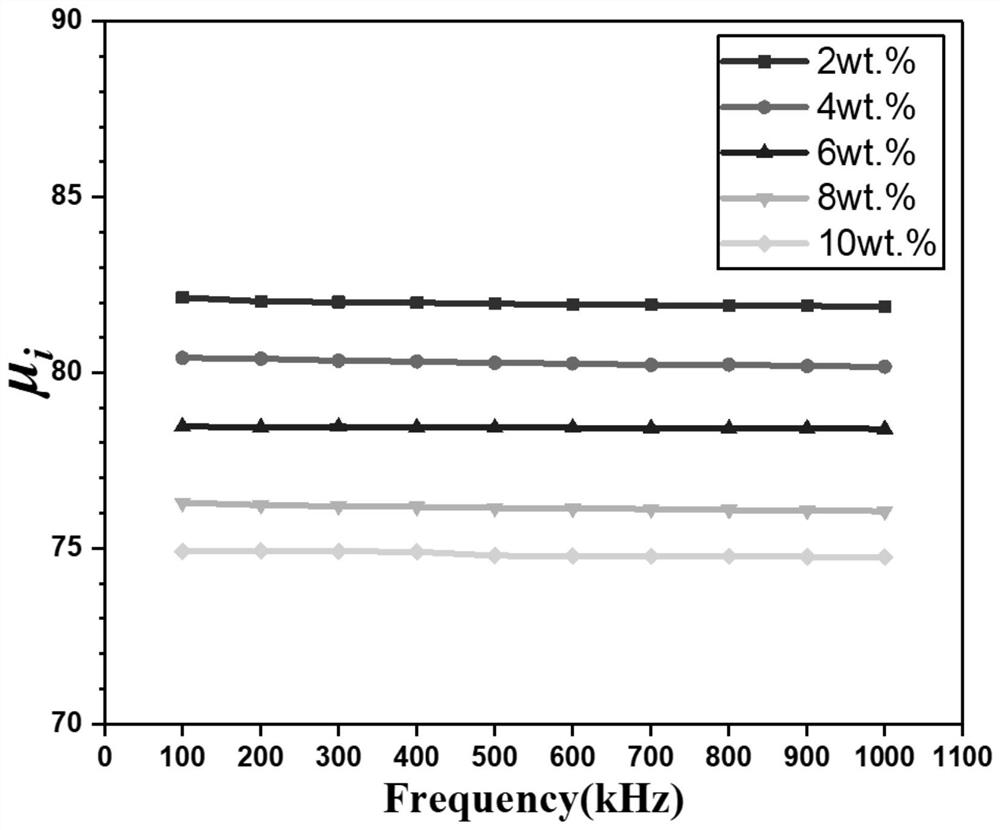

[0044] 4. Mix the phosphating FeSiAl magnetic powder and MnZn ferrite powder, in which the magnetic permeability of MnZn ferrite is 1400, and the addition amount is 6% of the mass of the FeSiAl magnetic powder. Use a high-energy ball mill f...

Embodiment 2

[0053] The preparation method of the stable magnetic permeability and low loss FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core in this embodiment includes the following steps:

[0054] 1. Take crushed FeSiAl powder, the composition of which is Si: 13%, Al: 4%, and the rest is Fe. Pass the crushed powder through a sieve, and select the powder under a 200 mesh sieve (<75 microns);

[0055] 2. Put the FeSiAl magnetic powder into the atmosphere furnace, pass in the mixed gas of hydrogen and argon, control the temperature at 800°C, and anneal for 0.5h;

[0056] 3. Adding the annealed FeSiAl magnetic powder to an aqueous phosphoric acid solution with a solute mass percentage of 1.5wt.% for phosphating and drying to obtain phosphating FeSiAl magnetic powder;

[0057] 4. Mix the phosphating FeSiAl magnetic powder with MnZn ferrite powder, wherein the MnZn ferrite has a magnetic permeability of 2000, and the amount added is 6% of the mass of the FeSiAl magnetic powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com