Wide-temperature low-power consumption ferrimagnetism material

A magnetic material and ferrite technology, which is applied in the field of ferrite magnetic materials with wide temperature and low power loss, can solve the problems of difficulty in eliminating the temperature gradient between the central part and the peripheral part, diluting negative effects, and difficulty in energy saving, etc., to achieve porosity Low, eliminate negative effects, high resistivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

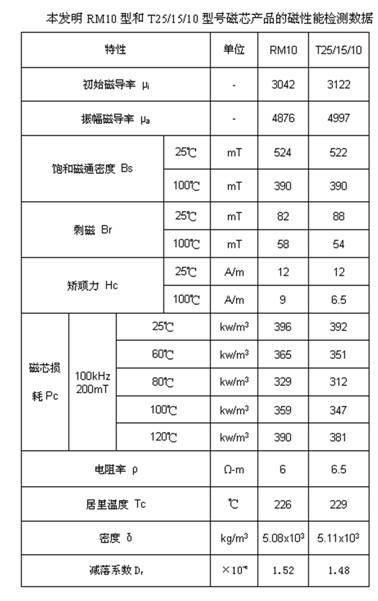

[0026] Embodiment: the production process of RM10 type and T25 / 15 / 10 type magnetic core products of the present invention is as follows:

[0027] (1) Ingredients: Fe 2 O53.4mol%, manganese powder 37.3mol%, ZnO9.1mol%, Co 2 o 3 0.2 mol%; (2) Add manganese powder and ZnO to the reaction tank filled with deionized aqueous solution with HCl accounting for 6.5%, and then add Fe 2 o 3 and Co 2 o 3 , fully stirred, the binary reaction is heated by steam to control the solution temperature at 70±2°C, and the pH value of each reaction section is controlled by passing ammonia to 5±1; (3) Pass the synthetic slurry obtained in step (2) through Drying in a drying tower to dry the synthetic slurry until the water content is less than 0.7%, and the flow angle is less than 31°; (4) The material obtained in step (3) is pre-fired in a rotary kiln at a temperature of 930°C for 30 minutes , to ferrite 96% of the material; (5) Add 500ppmCaO, 200ppmZrO 2 , 200ppmNb 2 o 5 and 400ppmTiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com