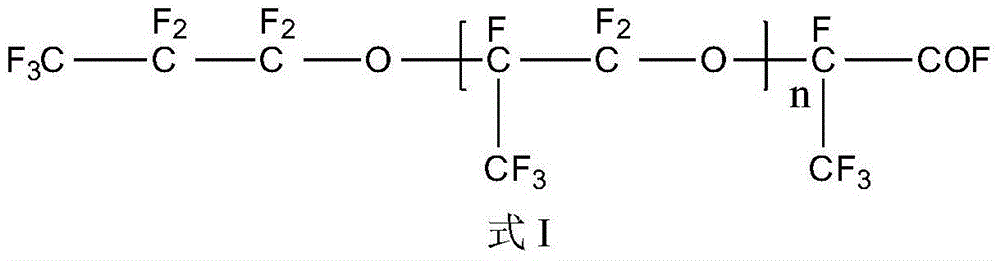

Preparation method for hexafluoropropylene oxide homopolymers

A technology of hexafluoropropylene oxide and homopolymer, which is applied in the field of preparation of hexafluoropropylene oxide homopolymer, which can solve the problem of inaccurate control of polymerization degree, inability to meet high-performance perfluoropolyether lubricating oil, difficulty in recycling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

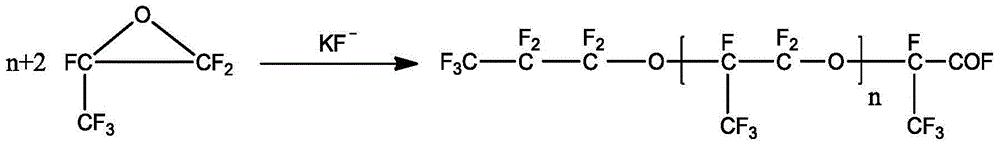

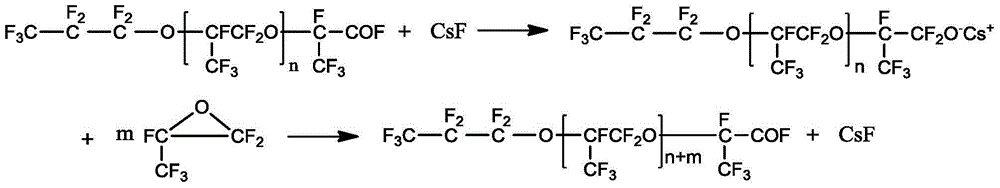

Method used

Image

Examples

preparation example Construction

[0015] According to the preparation method provided by the technical solution of the present invention, in some embodiments, the reaction temperature is lowered each time by 5-10°C.

[0016] In some embodiments, the stirring reaction time is 1-3 hours.

[0017] The solvent of the catalyst potassium fluoride or cesium fluoride, in theory, the polar aprotic solvent can be used as the solvent of the catalyst. In the technical scheme of the present invention, the solvent used as the catalyst is a mixed solution of tetraethylene glycol dimethyl ether and a fluorine-containing solvent. Mixed with fluorine-containing solvent, stirred and filtered at room temperature. The mixture of tetraethylene glycol dimethyl ether and fluorine-containing solvent has the effect of stabilizing fluoride ions in the reaction process, and this effect is well known in the art.

[0018] According to the preparation method provided by the technical solution of the present invention, the cesium fluoride ...

Embodiment 1

[0039] N 2 Under protection, add 7.2 g of strictly dried potassium fluoride into 150 ml of a mixture of tetraethylene glycol dimethyl ether and hexafluoropropylene dimer (volume ratio 1:1), stir at room temperature for 0.5 h, and then filter. Vacuumize the strictly dry 2L reaction kettle to -1 bar, add the filtrate to the reaction kettle, and feed according to the method in Table 1 at 0°C, the feeding rate is: 0.5g / min of hexafluoropropylene oxide, 0.05ml of cesium fluoride saturated solution / min. A total of 480 g of hexafluoropropylene oxide was added, wherein the cesium fluoride saturated solution was a cesium fluoride saturated solution with a volume ratio of tetraethylene glycol dimethyl ether to hexafluoropropylene dimer at room temperature of 1:1. After the feeding is completed, the temperature in the kettle is slowly raised to room temperature (25° C.), and the product hexafluoropropylene oxide homopolymer is obtained by discharging from the bottom of the kettle. Afte...

Embodiment 2

[0044] N 2 Under protection, add 7.2 g of strictly dried potassium fluoride into 150 ml of a mixture of tetraethylene glycol dimethyl ether and hexafluoropropylene dimer (4:1 by volume), stir at room temperature for 0.5 h, and then filter. Vacuumize the strictly dry 2L reaction kettle to -1 bar, add the filtrate to the reaction kettle, and feed according to the method in Table 2 at 0°C. The feeding rate is: hexafluoropropylene oxide 1g / min, cesium fluoride saturated solution 0.1ml / min. A total of 960 g of hexafluoropropylene oxide was added, wherein the cesium fluoride saturated solution was a cesium fluoride saturated solution with a volume ratio of tetraethylene glycol dimethyl ether to hexafluoropropylene dimer at room temperature of 1:1. After the feeding is completed, the temperature in the kettle is slowly raised to room temperature (25° C.), and the product hexafluoropropylene oxide homopolymer is obtained by discharging from the bottom of the kettle. After its methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com