Low-temperature reinforced type heating cable sheathing material and preparation method thereof

A heat tracing cable, reinforced technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor low temperature resistance and low mechanical strength, and achieve good low temperature resistance, good mechanical strength, excellent The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

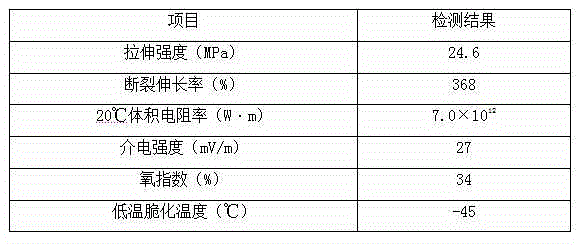

[0013] A low temperature reinforced heat tracing cable sheath material, made of the following raw materials (kg): nylon 66 48, polytetrafluoroethylene 36, polyamideimide 24, low molecular weight polybutene 12, magnesium borate crystal Whiskers 16, illite powder 14, tetraethylene glycol diheptanoate 12, nano-zirconium boride 8, magnesium oleate 4, diisodecyl adipate 12, hydroxyaluminum distearate 5, caprylic acid Triglyceride 7, dioctyl sebacate 12, epoxy fatty acid methyl ester 8, polyethylene oxide sorbitan monooleate 1.5, additive 3.5;

[0014] The preparation method of the auxiliary agent is as follows: (1) Take the following raw materials by weight (kg): thiourea dioxide 2.5, calcium sulfite 7, chlorobridge anhydride 3.5, flue ash 13, ethylhexyl palmitate 2.5, Diethyl succinate 6, aluminum titanate 8, methacrylic acid chromium chloride complex 2.5, sucrose benzoate 4, dibutyl maleate 8, lanolin 4.5; (2) Calcium sulfite, Mix aluminum titanate, ethylhexyl palmitate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com