DOT4 boric acid ester type brake fluid

A technology of brake fluid and borate, which is applied in the field of DOT4 borate brake fluid, can solve the problems of unresolved borate hydrolysis stability, alcohol ether technology is difficult to meet the requirements of the new national standards, etc., to achieve Addresses the effect of long-term storage hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

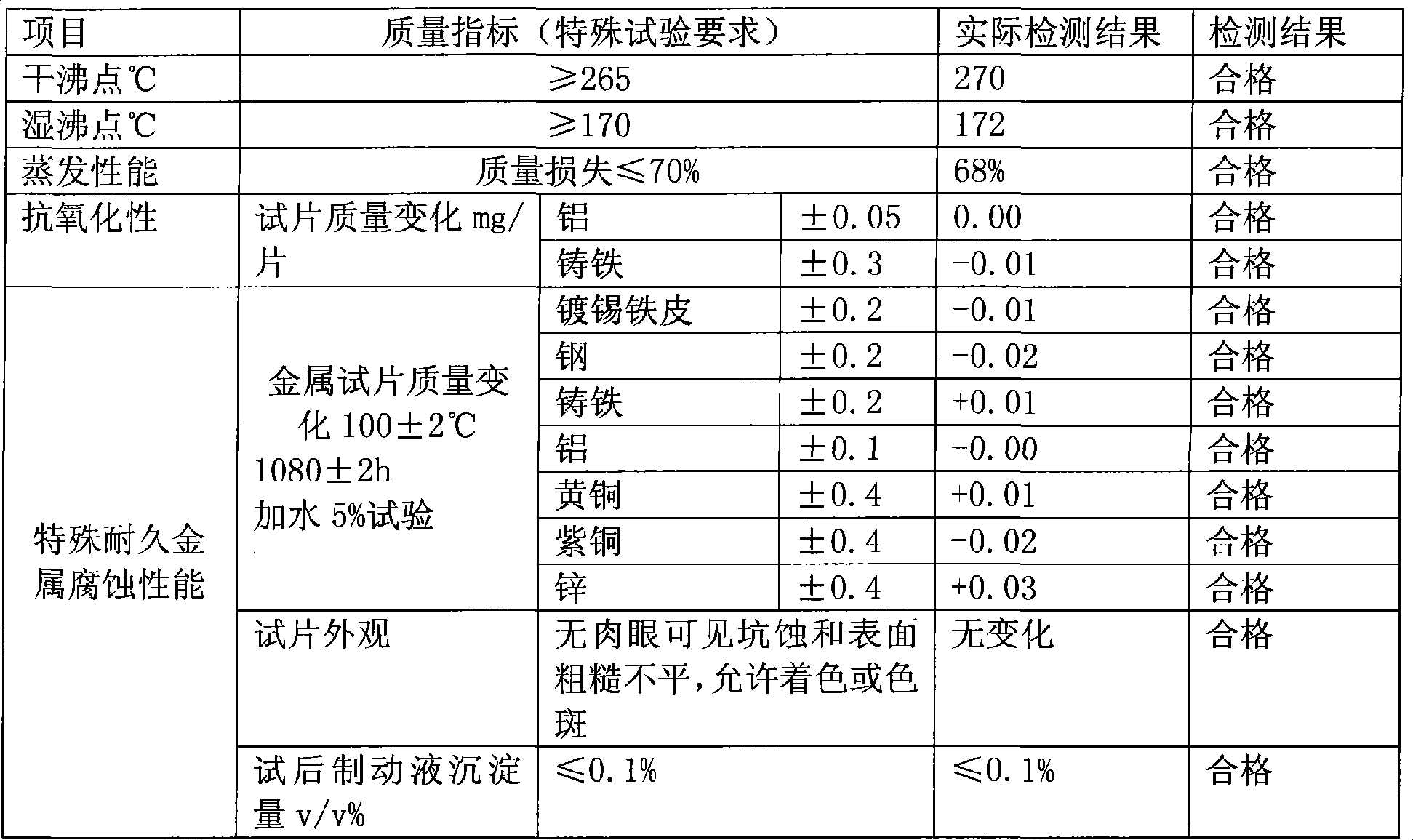

[0013] Add successively 44.9 kilograms of triethylene glycol methyl ether, 158 kilograms of tetraethylene glycol methyl ether, 20 kilograms of diethylene glycol, and 750 kilograms of alcohol ether borate (wet balance reflux boiling point) in the reactor of 1.5T : 220°C, -40°C low temperature kinematic viscosity: 1000CST, PH: 5.0), start stirring, and add 2 kg of benzotriazole, 3.5 kg of N-ethylmorpholine, 6 kg every 10 minutes in the following order Bisphenol A, 0.6 kg of dodecyl thiodipropionate, 2 kg of 2.6-di-tert-butyl-4-methylphenol, 4 kg of T746, 1 kg of mercaptobenzothiazole, stirred for 2 hours Finally, add 8 kg of tri-n-butylamine, continue to stir for 4 hours and then filter and pack through a 0.1-0.5um filter.

[0014] The test results of the main technical indicators are as follows (using the special durability test requirements for testing hydrolytic stability):

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com