Metal phase molybdenum disulfide nano-structure and preparation method thereof

A technology of molybdenum disulfide and nanostructure, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of unobtainable purity, rich defects, high synthesis cost, etc., and achieve the effect of increasing active sites and regulating morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] A method for preparing metallic phase molybdenum disulfide nanostructures includes the following steps:

[0039] 1. Dissolve 0.06g sodium molybdate and 0.12g thioacetamide in 40mL deionized water, stir vigorously for 40 minutes to form a homogeneous solution, wherein the molar concentration of sodium molybdate is 6.25mmol / L, add thioacetamide The amount is 6.4 times the concentration of sodium molybdate substance, which is 40 mmol / L.

[0040] 2. Transfer the solution to a stainless steel reactor, and react in an oven at 200°C for 24 hours. After the reaction stops, cool to room temperature naturally.

[0041] 3. Centrifuge the black precipitate in the reactor at 6500 rpm, wash it with deionized water three times, and finally disperse it into deionized water. A dispersion liquid of metallic phase molybdenum disulfide nanostructure is obtained.

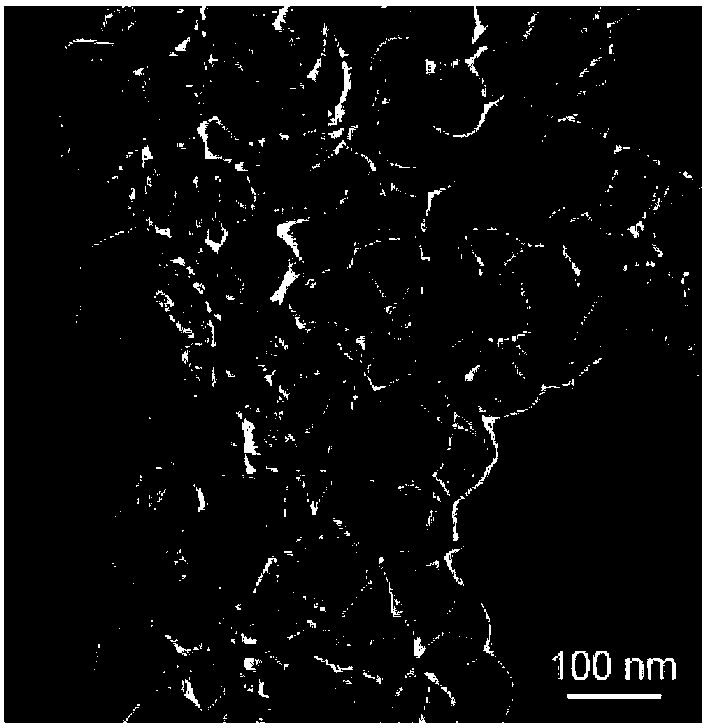

[0042] Obtain the metallic phase molybdenum disulfide nanosheets with a smaller size, more edge states and an average size of 75nm, su...

Embodiment 2-3

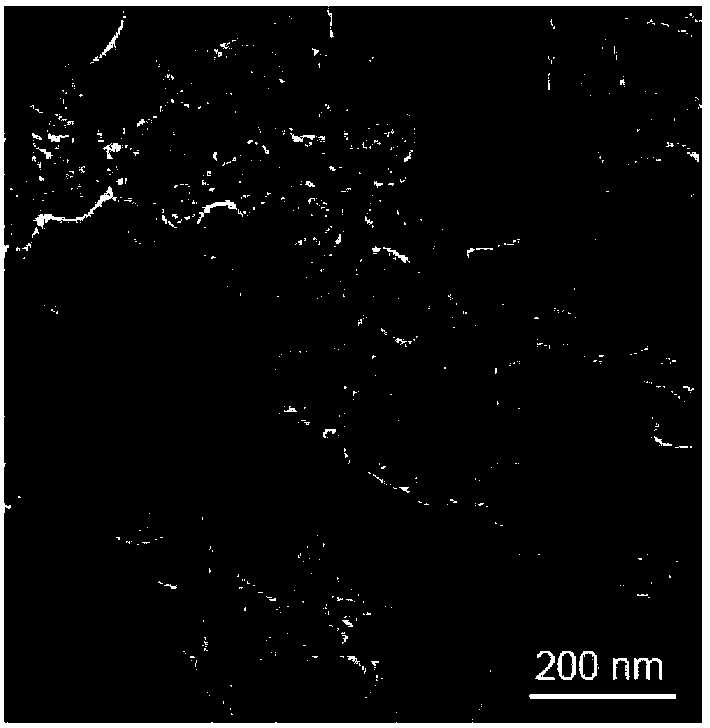

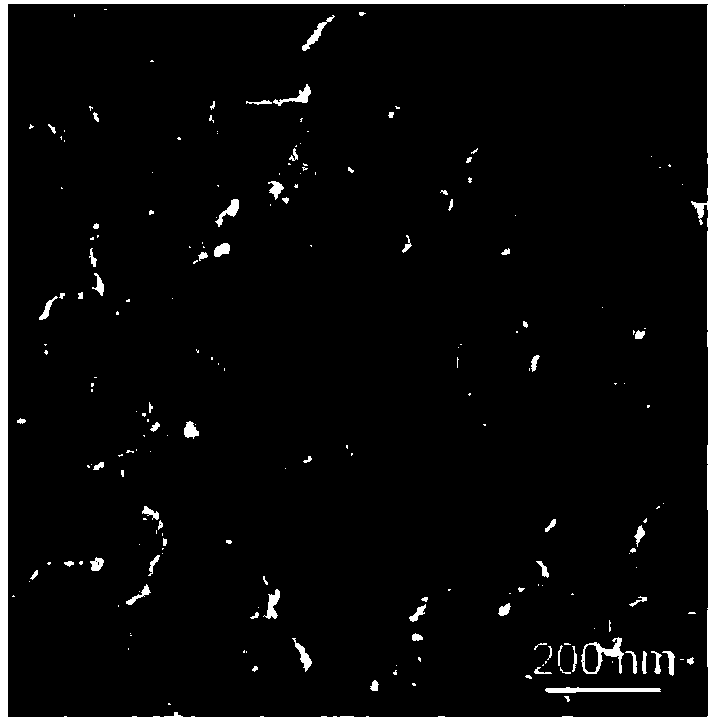

[0043] Example 2-3: The influence of the concentration of thioacetamide added in step 2 on the growth size of the metallic phase molybdenum disulfide.

example 2

[0045] In this example, except for adding in step 2, the added thioacetamide is three times the amount of sodium molybdate, which is 18.75mmol / L, and the other steps are the same as in Example 1. The obtained metal phase disulfide The average size of the molybdenum nanosheets is 90 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com