Green solvent system for preparing perovskite layer of perovskite solar cell and mixed solution

A solar cell and mixed solution technology, which is applied in electric solid devices, circuits, photovoltaic power generation, etc., can solve the problems of not conforming to the concept of green process development, unfavorable perovskite solar cells, and not many perovskite solar cells, etc. The effect of adapting to market demand, simple preparation process, and easy industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a method for preparing a perovskite layer of a perovskite solar cell, comprising the following steps:

[0049] 1) Under a protective atmosphere, spin-coat the mixed solution described in any one of the above technical solutions on the anode buffer layer to obtain a perovskite layer.

[0050] The present invention is not particularly limited to the selection of the anode buffer layer, and the conventional anode buffer layer or hole transport layer of a perovskite solar cell well known to those skilled in the art can be used. Those skilled in the art can according to the actual application situation, Product requirements and quality requirements are selected and adjusted. The anode buffer layer of the present invention, that is, the hole transport layer, preferably includes a spiro-OMeTAD layer, a PEDOT:PSS layer, a PTAA layer or a NiOx layer, and more preferably preferably includes a spiro-OMeTAD layer. layer, PEDOT:PSS layer or NiOx layer, most pr...

Embodiment 1

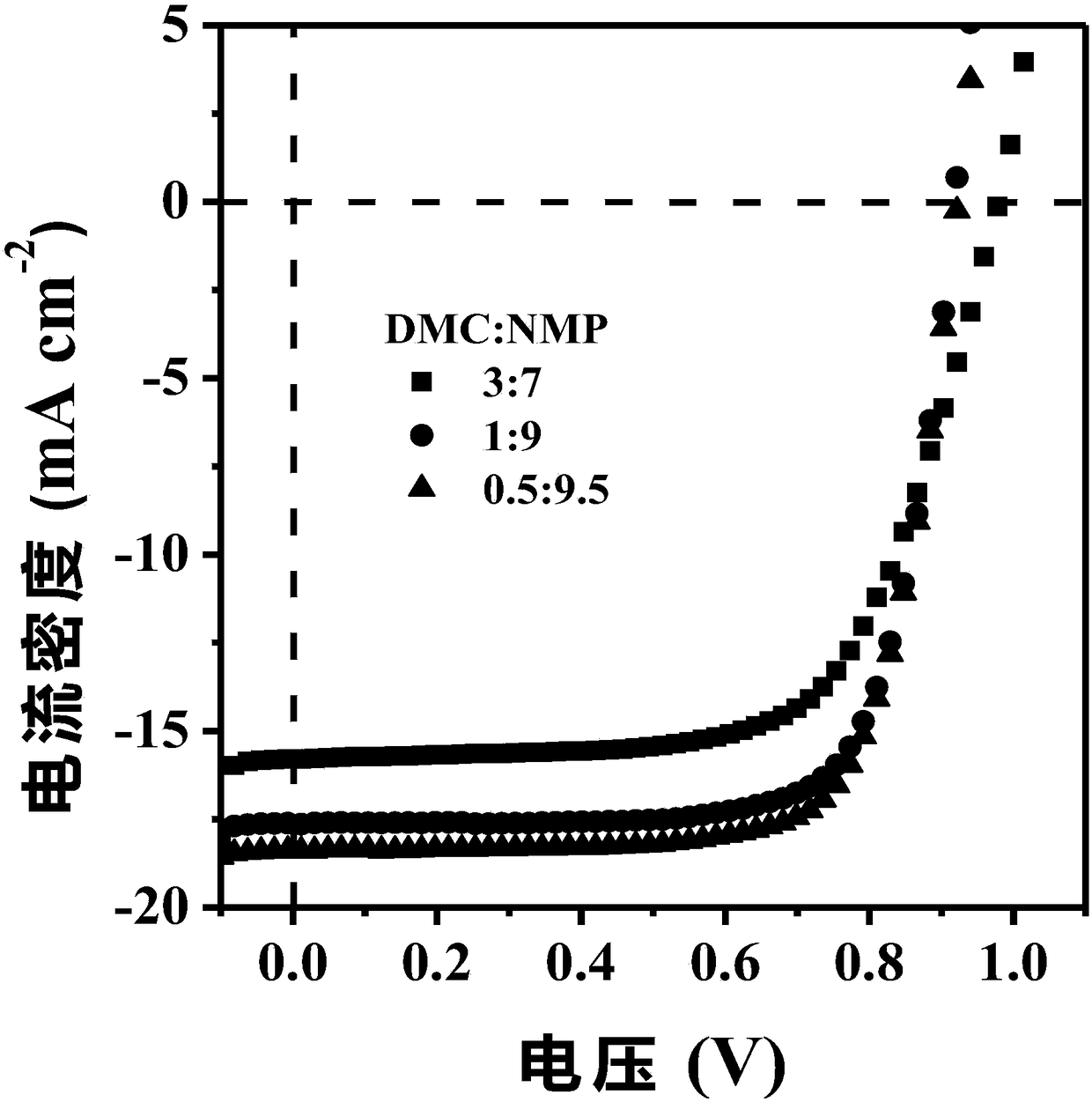

[0061] The novel green solvent system used in perovskite solar cells in this embodiment is composed of two solvents, dimethyl carbonate and N-methylpyrrolidone, with volume ratios of 3:7, 1:9 and 0.5:9.5, respectively.

[0062] The solubility test and film-forming property test of perovskite are carried out on the new green solvent system of this embodiment; the ultraviolet absorption spectrum test, SEM test and photovoltaic characteristic test are carried out on the perovskite film and device prepared by the new green solvent system, as follows :

[0063] 1. Carry out the solubility test of perovskite to the novel green solvent system of the present embodiment,

[0064] see figure 1 , figure 1 It is a photograph of the appearance of the mixed solvent system provided in Example 1 of the present invention after mixing with the perovskite raw material. Among them, the picture on the left is direct to MAI white powder and PbI 2 Dimethyl carbonate solvent is added to the yello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com