Capsule type catalyst for preparing low-carbon olefin by catalyzing synthesis gas and preparation method thereof

A low-carbon olefin and synthesis gas technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the role of the carrier cannot be fully exerted, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

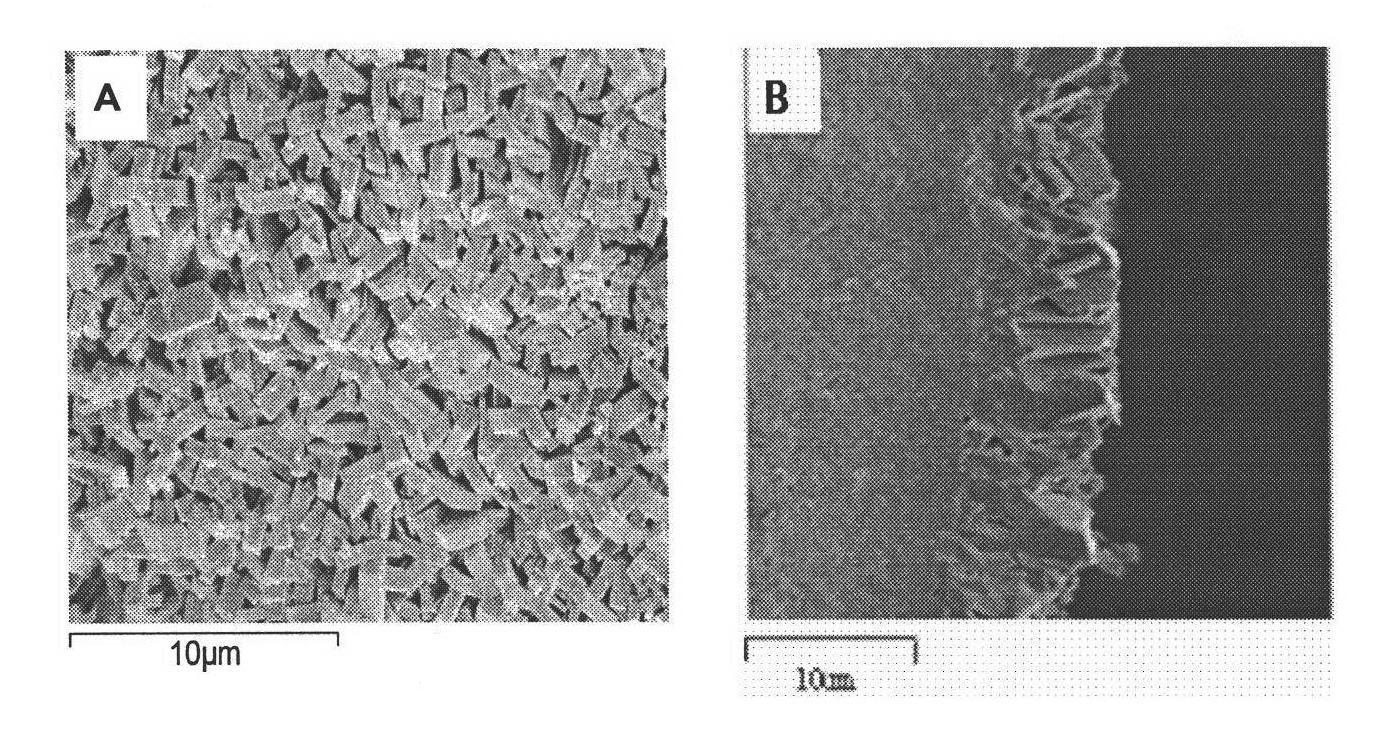

Image

Examples

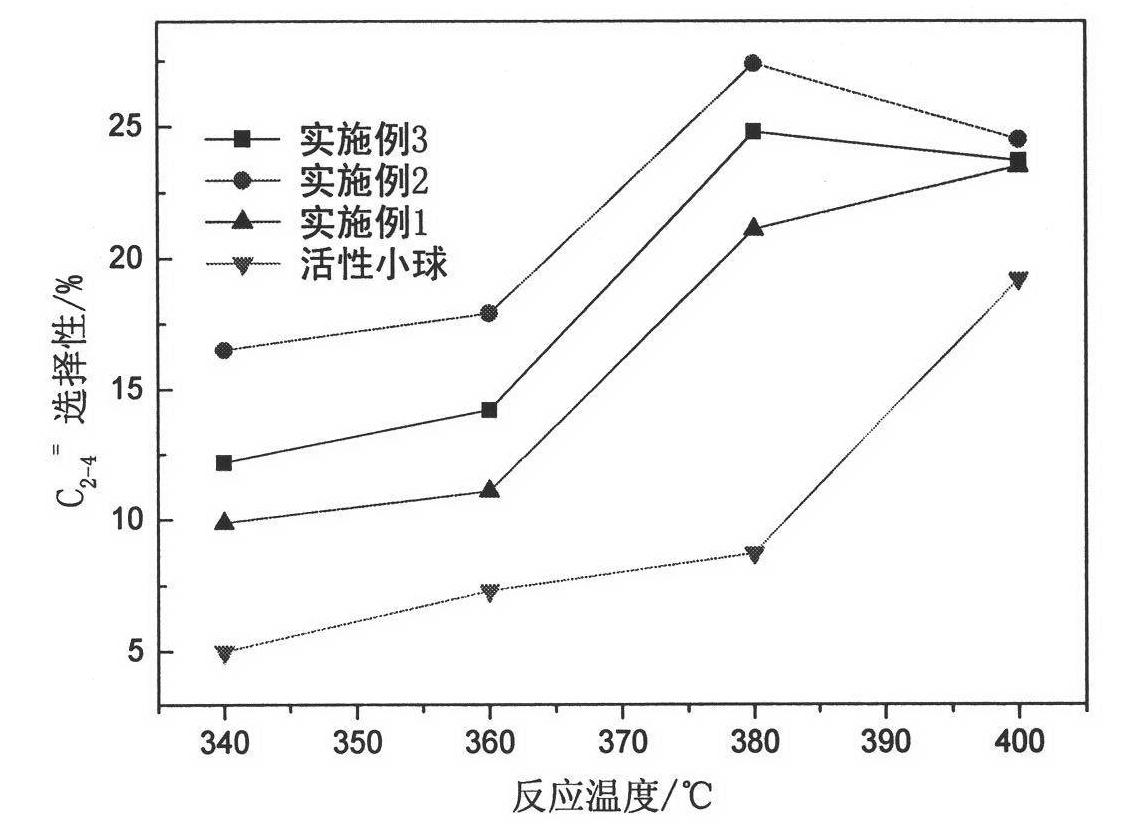

Embodiment 1

[0015] After weighing 22g ferric nitrate and dissolving it in water, mix it with 15g SiO 2 Pellets (1.18-2.15mm) were impregnated with equal volume for 1 hour, then dried at 100°C for 0.5h, and calcined at 550°C for 6 hours to obtain active pellets with catalytic conversion of synthesis gas to produce hydrocarbons.

[0016] In a 100ml polytetrafluoroethylene kettle, configure 60ml of a mixed solution of silane coupling agent (AP-TMS) and absolute ethanol with a volume ratio of 1:35, put 2g of the prepared active pellets, and keep it airtight at 100°C for 4h. Rinse with ethanol to remove residual silane coupling agent on the surface, then mix with 0.3wt% ethanol solution of 60ml Silicalite-1 molecular sieve seed crystals, place in a 100ml polytetrafluoroethylene kettle, keep it airtight at 100°C for 4 hours, take it out, and rinse with ethanol , and then dried at 100° C. and calcined at 300° C. for 6 hours to obtain pellets coupled with Silicalite-1 molecular sieve crystal seed...

Embodiment 2

[0019] The active pellets prepared in Example 1 were used to prepare capsule-type catalysts, and the implementation method was the same as in Example 1, except that the crystallization time was 2 days, and other steps were the same.

Embodiment 3

[0021] The active pellets prepared in Example 1 are used to prepare capsule-type catalysts, and the implementation method is the same as in Example 1, except that the film-forming liquid formula is changed to TEOS: 0.25TPAOH: 350H 2 Except for O, other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com