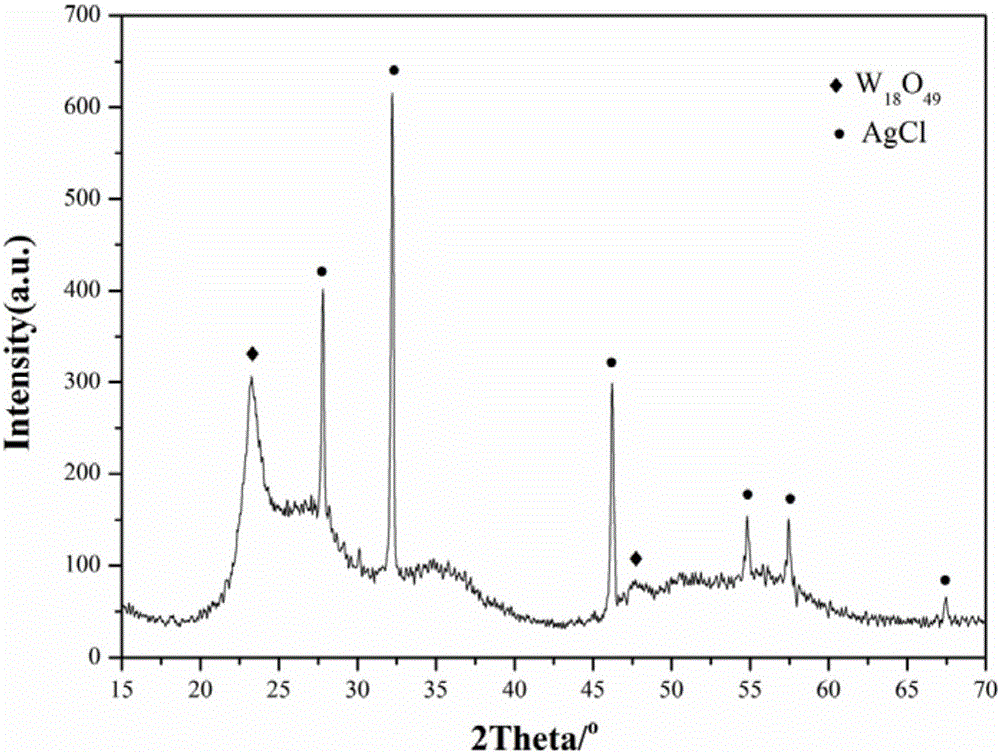

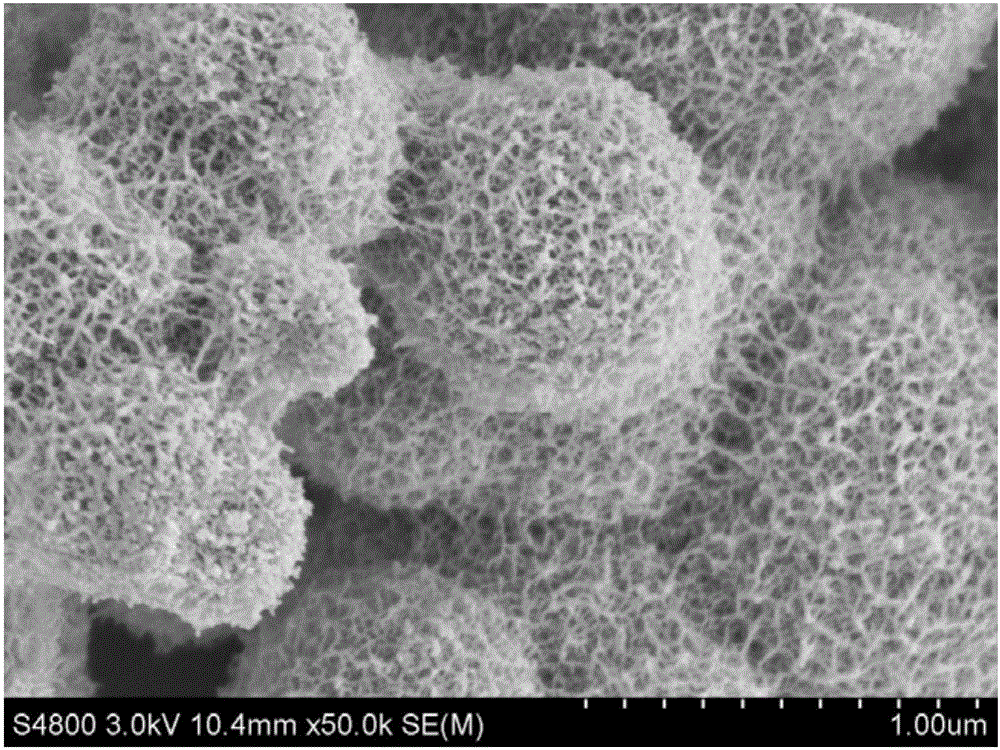

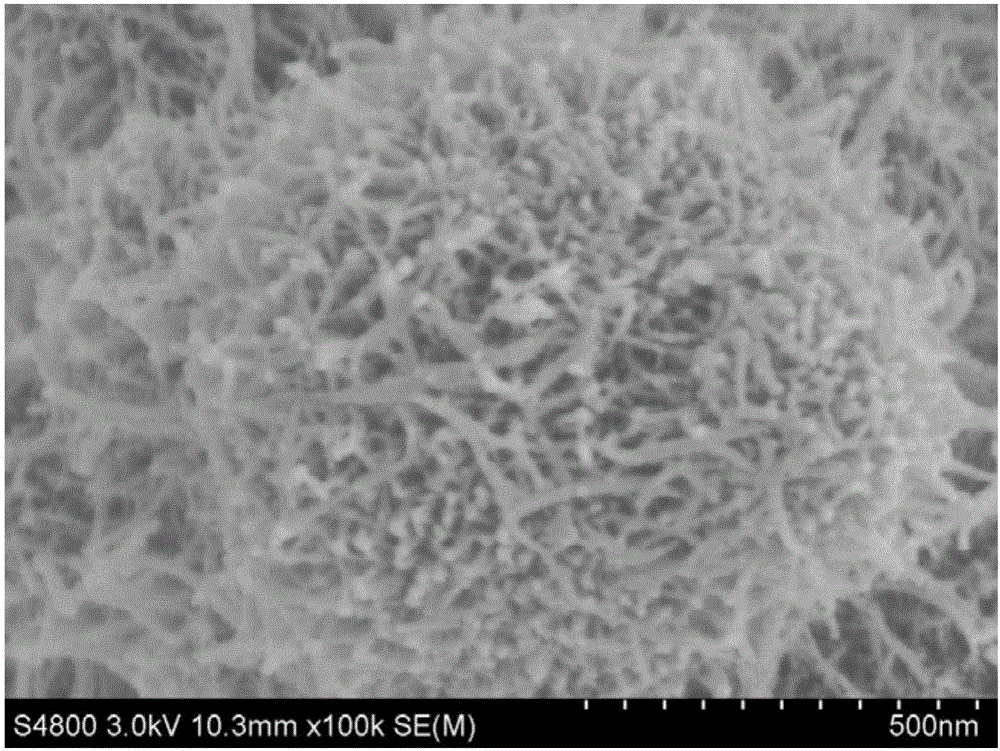

Method for preparing spherical AgCl/W18O49 composite material

A technology of W18O49 and composite materials, which is applied in the field of preparing spherical AgCl/W18O49 composite materials, can solve the problems of low product purity, high sintering temperature, and long holding time, and achieve uniform chemical composition, low reaction temperature, and easy control of the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh 0.7931g analytically pure WCl 6 , Prepare 0.05mol / L solution A with 40mL absolute ethanol.

[0030] 2) Weigh 0.1132g of analytically pure AgNO in A solution 3 , making AgNO 3 and WCl 6 The ratio of the amount of the substances is 1:3, and the solution B is obtained.

[0031] 3) Seal solution B with plastic wrap to avoid contact with air, stir with a magnetic stirrer for 30 minutes, and treat with ultrasonic (80Hz) for 20 minutes

[0032] 4) Pour the homogeneously mixed solution B into a 100mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 40%.

[0033] 5) Feed 20min of N into the reactor 2 To reduce the oxygen in the reactor.

[0034] 6) Put the sealed reaction kettle into the homogeneous hydrothermal reactor, set the temperature parameter to 160° C., and the reaction time to 24 hours.

[0035] 7) Cool to room temperature after the reaction, and centrifuge and wash the final reactant three times with absolute ethanol. The c...

Embodiment 2

[0039] 1) Weigh 0.3569g analytically pure WCl 6 , Prepare 0.03mol / L solution A with 30mL absolute ethanol.

[0040] 2) Weigh 0.1529g analytically pure AgNO in A solution 3 , making AgNO 3 and WCl 6 The ratio of the amounts of substances is 1:1 to obtain solution B.

[0041] 3) Seal solution B with plastic wrap to avoid contact with air, stir with a magnetic stirrer for 20 minutes, and treat with ultrasonic (60Hz) for 30 minutes

[0042] 4) Pour the homogeneously mixed solution B into a 100mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 30%.

[0043] 5) Feed 30min of N into the reactor 2 To reduce the oxygen in the reactor.

[0044] 6) Put the sealed reactor into a homogeneous hydrothermal reactor, set the temperature parameter to 150° C., and the reaction time to 18 hours.

[0045] 7) Cool to room temperature after the reaction, and centrifuge and wash the final reactant three times with absolute ethanol. Put the centrifuged material int...

Embodiment 3

[0048] 1) Weigh 1.9035g analytically pure WCl 6 , Prepare 0.03mol / L solution A with 30mL absolute ethanol.

[0049] 2) Weigh 0.1631g of analytically pure AgNO in A solution 3 , making AgNO 3 and WCl 6 The ratio of the amount of substances is 1:5 to obtain solution B.

[0050] 3) Seal solution B with plastic wrap to avoid contact with air, stir with a magnetic stirrer for 40 minutes, and treat with ultrasonic (80Hz) for 20 minutes

[0051] 4) Pour the homogeneously mixed solution B into a 100mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 30%.

[0052] 5) Feed 20min of N into the reactor 2 To reduce the oxygen in the reactor.

[0053] 6) Put the sealed reactor into a homogeneous hydrothermal reactor, set the temperature parameter to 170° C., and the reaction time to 25 hours.

[0054] 7) Cool to room temperature after the reaction, and centrifuge and wash the final reactant three times with absolute ethanol. The centrifuged material was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com