Method using emulsion electricity texture to prepare beaded filaments

An emulsion and bead-like technology, which is applied in the field of emulsion electrospinning to prepare bead-like fibers, achieves the effect of mild conditions, great application prospects, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

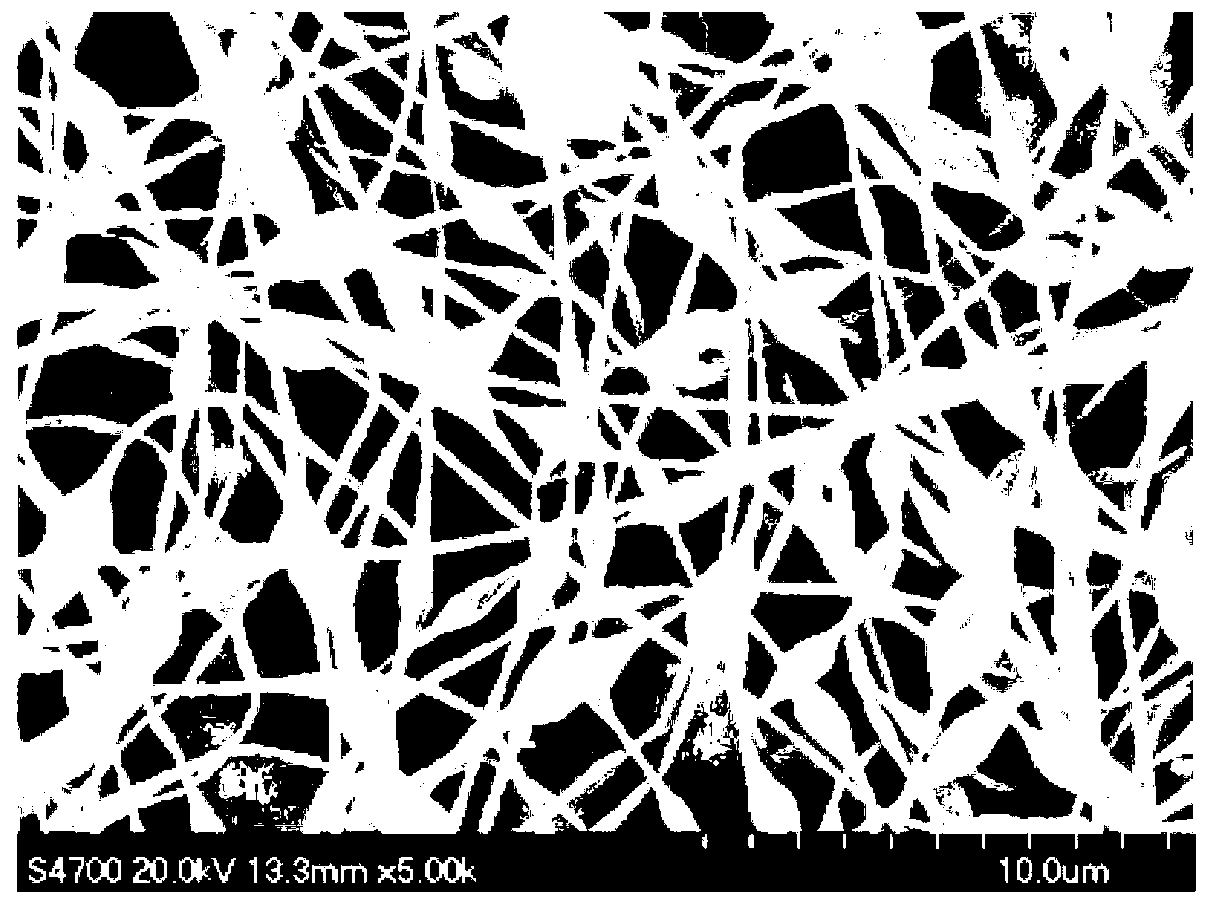

Embodiment 1

[0022] (1) Preparation of polystyrene emulsion with a solid content of 25 wt%:

[0023] Add 1.2 g of sodium lauryl sulfate, 0.018 g of sodium bicarbonate and 180 g of deionized water into a 500 mL four-neck flask equipped with a magnetic stirrer, reflux condenser and thermometer, and stir and mix well. Add 60 g of styrene monomer under stirring, feed nitrogen into the reaction system of the vessel to exhaust the oxygen, heat the temperature of the reaction system to 70°C, add 0.18 g of potassium persulfate (dissolved In 20 g of deionized water), the polymerization was initiated. After 3 h of polymerization, the reaction was stopped and cooled naturally to obtain a polystyrene emulsion with a solid content of 25 wt%.

[0024] (2) Take an appropriate amount of the prepared polystyrene emulsion in an Erlenmeyer flask, add dropwise a poloxamer surfactant of 3 wt% relative to the mass of polystyrene under magnetic stirring, mix well, and mix with PS / PVA PVA solution (10 wt%) was a...

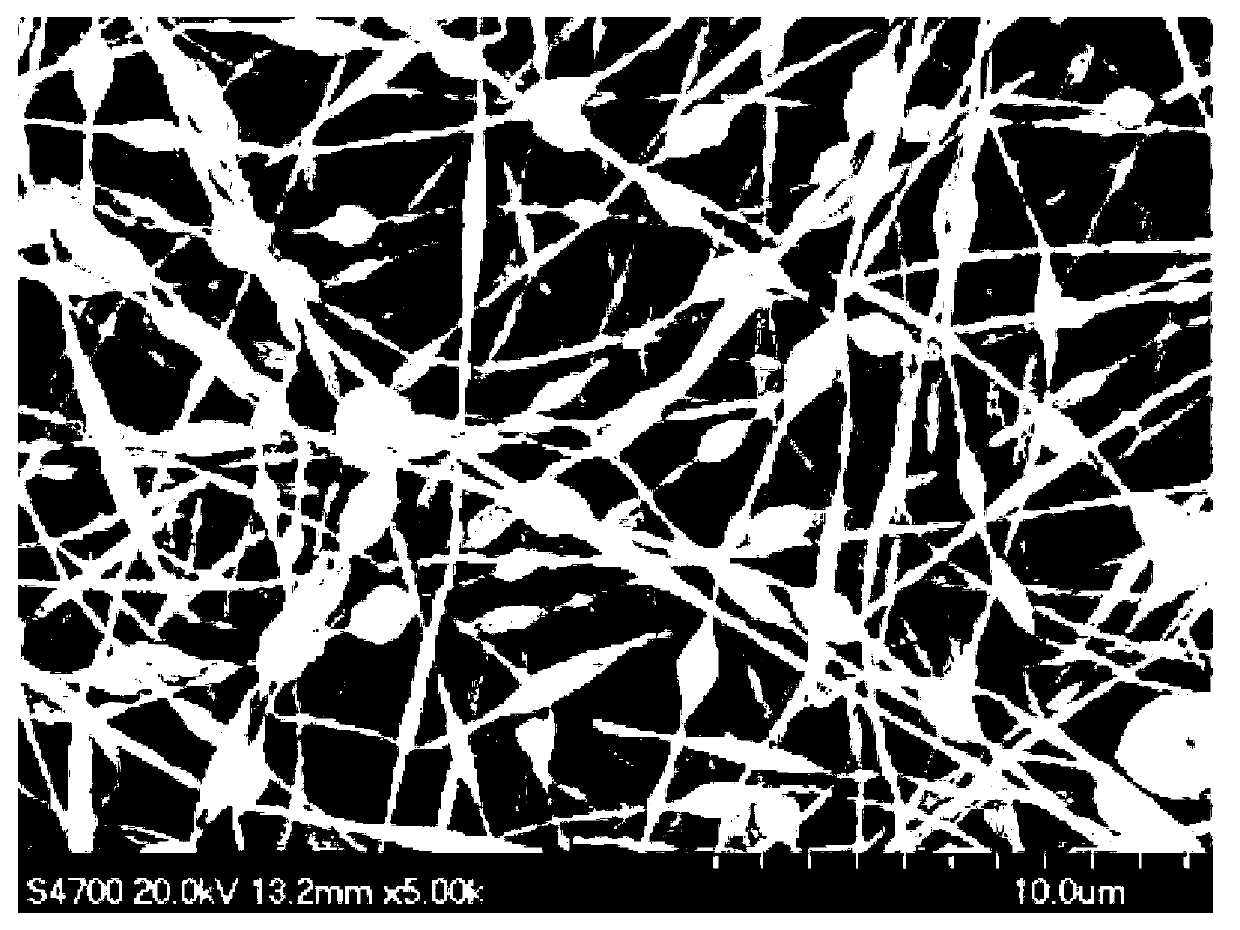

Embodiment 2

[0027] (1) Preparation of polystyrene emulsion with a solid content of 25 wt%:

[0028] Add 1.2 g of sodium lauryl sulfate, 0.018 g of sodium bicarbonate and 180 g of deionized water into a 500 mL four-neck flask equipped with a magnetic stirrer, reflux condenser and thermometer, and stir and mix well. Add 60 g of styrene monomer under stirring, feed nitrogen into the reaction system of the vessel to exhaust the oxygen, heat the temperature of the reaction system to 70°C, add 0.18 g of potassium persulfate (dissolved In 20 g of deionized water), the polymerization was initiated. After 3 h of polymerization, the reaction was stopped and cooled naturally to obtain a polystyrene emulsion with a solid content of 25 wt%.

[0029] (2) Take an appropriate amount of the prepared polystyrene emulsion in an Erlenmeyer flask, add 5 wt% poloxamer surfactant to the mass of polystyrene dropwise under magnetic stirring, mix well, and mix with PS / PVA PVA solution (10 wt%) was added dropwise ...

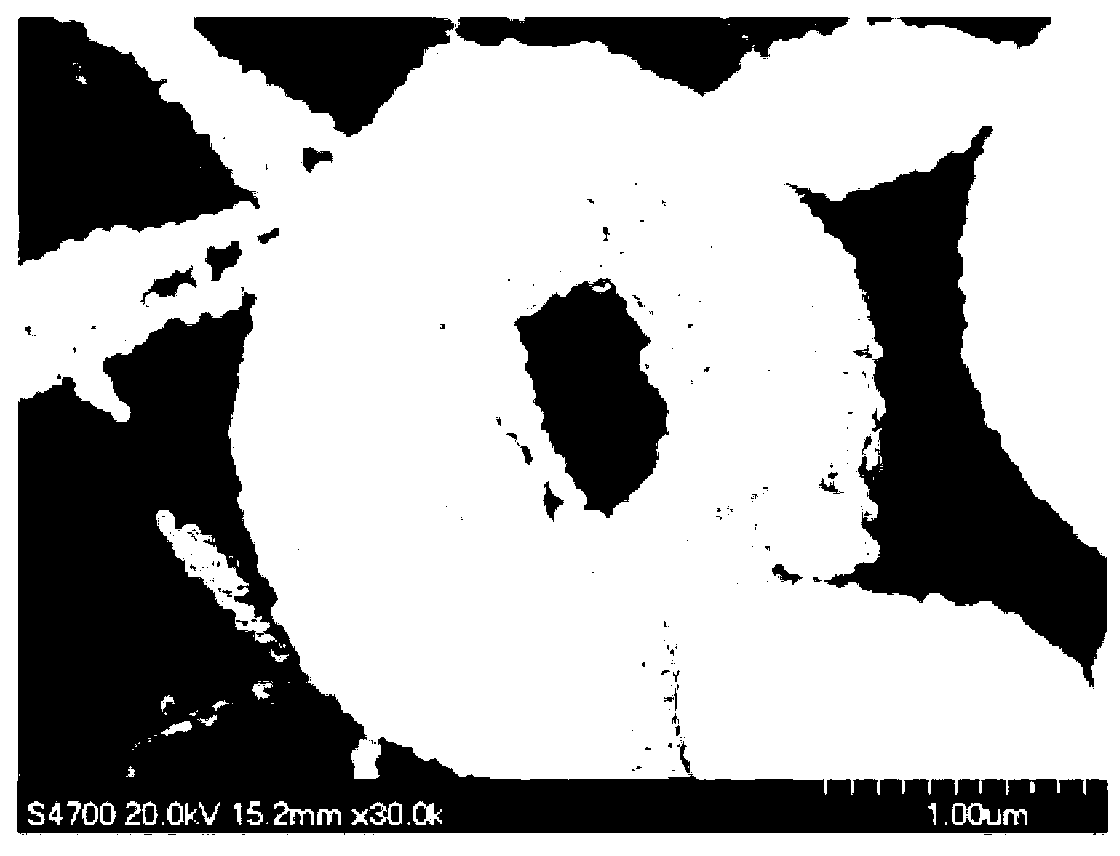

Embodiment 3

[0032] (1) Preparation of polystyrene emulsion with a solid content of 25 wt%:

[0033] Add 1.2 g of sodium lauryl sulfate, 0.018 g of sodium bicarbonate and 180 g of deionized water into a 500 mL four-neck flask equipped with a magnetic stirrer, reflux condenser and thermometer, and stir and mix well. Add 60 g of styrene monomer under stirring, feed nitrogen into the reaction system of the vessel to exhaust the oxygen, heat the temperature of the reaction system to 70°C, add 0.18 g of potassium persulfate (dissolved In 20 g of deionized water), the polymerization was initiated. After 3 h of polymerization, the reaction was stopped and cooled naturally to obtain a polystyrene emulsion with a solid content of 25 wt%.

[0034] (2) Take an appropriate amount of the prepared polystyrene emulsion in an Erlenmeyer flask, add dropwise a poloxamer surfactant of 7 wt% relative to the mass of polystyrene under magnetic stirring, mix well, and mix with PS / PVA PVA solution (10 wt%) was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com