Preparation method for hollow carbon material and product

A carbon material, hollow technology, applied in the field of preparation of new hollow carbon materials, can solve the problem of no hollow cavity, etc., achieve low cost, strong controllability, and realize the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

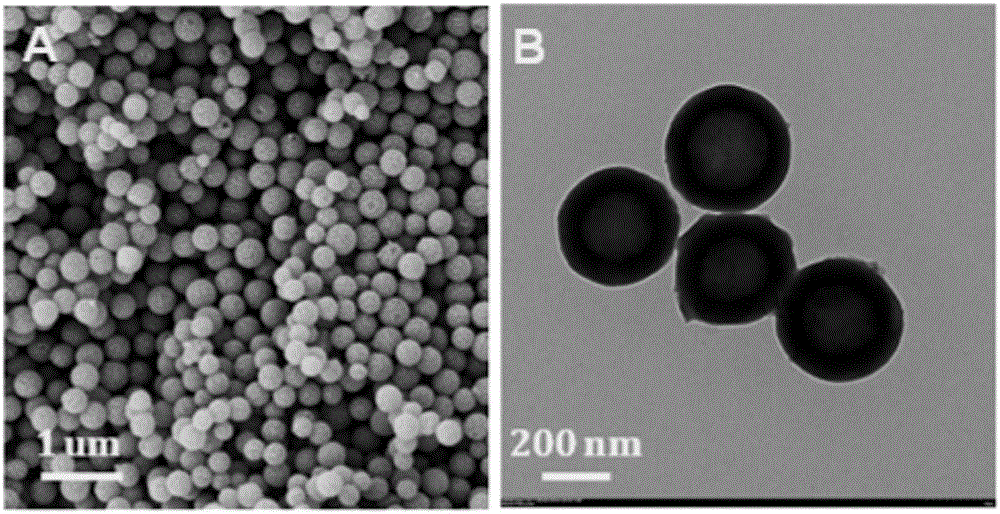

[0034] Embodiment 1: Taking glucose as carbon source

[0035] Dissolve 75mg of sodium oleate and 150mg of P123 in 30mL of water to obtain solution I; then dissolve 5g of glucose in 30mL of water to obtain solution II; then mix solution I and solution II and stir for 10min; at 160°C Hydrothermal for 24 hours, centrifuged, washed with water, and dried to obtain the precursor. The precursor was put into a muffle furnace and calcined in a nitrogen inert gas atmosphere at a heating rate of 10 °C / min, and calcined at 1000 °C for 1 h to obtain hollow carbon spheres. Relevant characterizations of prepared products such as figure 1 shown

Embodiment 2

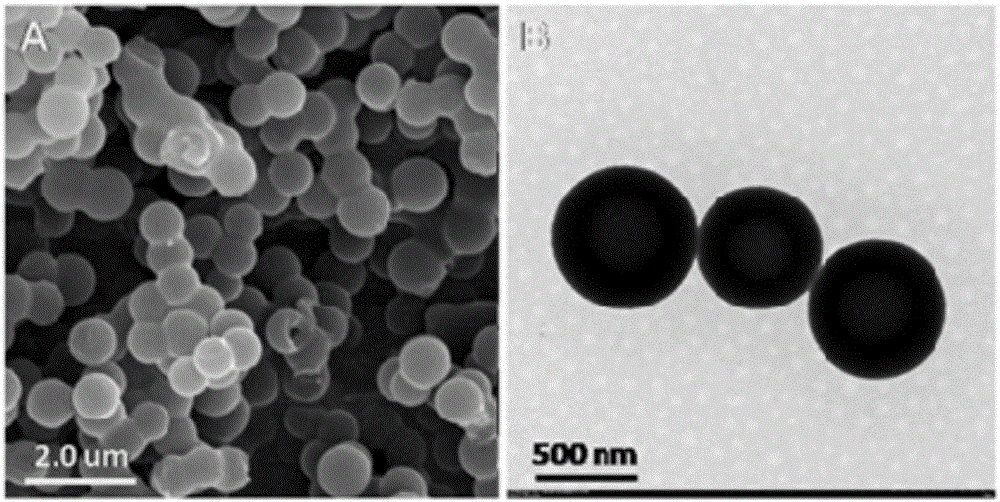

[0036] Embodiment 2: Taking fructose as carbon source

[0037] Dissolve 75mg of sodium oleate and 150mg of P123 in 30mL of water, then dissolve 5g of fructose in 30mL of water, then mix the two, stir for 10min; heat at 160°C for 24h, centrifuge, wash with water, and dry to obtain Hydrothermal products. The hydrothermal product was put into a muffle furnace and calcined in a nitrogen inert gas atmosphere at a heating rate of 10°C / min, and calcined at 1000°C for 1 hour to obtain hollow carbon spheres. The relevant characterization of the prepared product is as follows figure 2 shown.

Embodiment 3

[0038] Embodiment 3: Taking xylose as carbon source

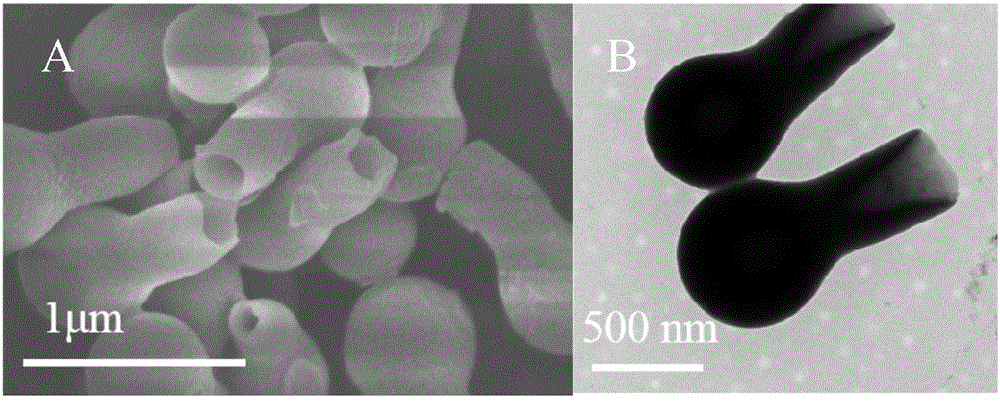

[0039] Dissolve 75mg of sodium oleate and 150mg of P123 in 30mL of water, then dissolve 5g of xylose in 30mL of water, then mix the two, stir for 10min; heat at 160°C for 24h, centrifuge, wash with water, and dry A hydrothermal product is obtained. The hydrothermal product was put into a muffle furnace and calcined in a nitrogen inert gas atmosphere at a heating rate of 10°C / min, and calcined at 1000°C for 1 hour to obtain a "racket-shaped" hollow carbon material. The relevant characterization of the prepared product is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com