Method for forming pleats on surface of elastomer film

A technology for elastomers and elastomer materials, which is applied in the field of elastomer surface processing and can solve problems such as complex regulation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

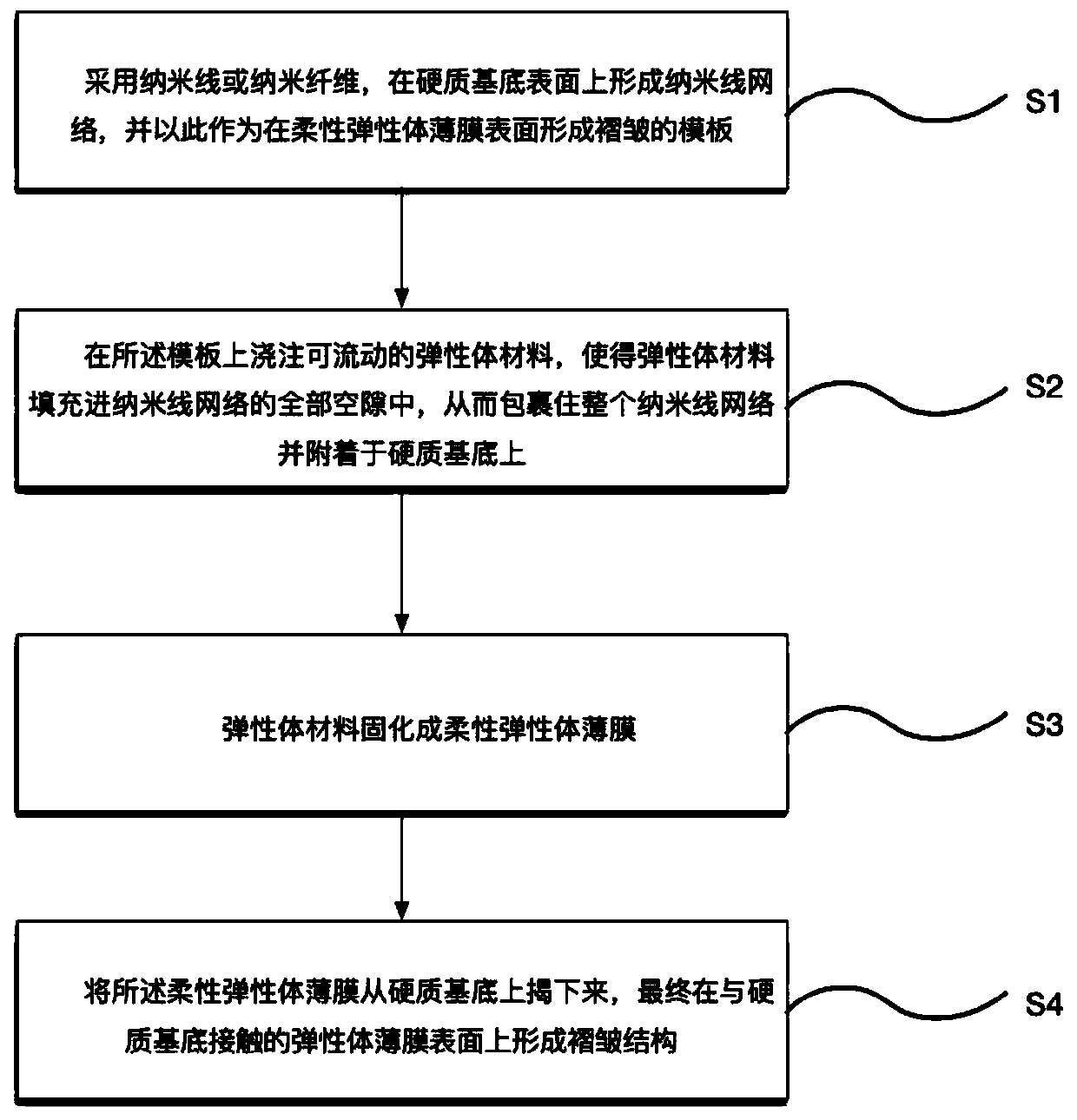

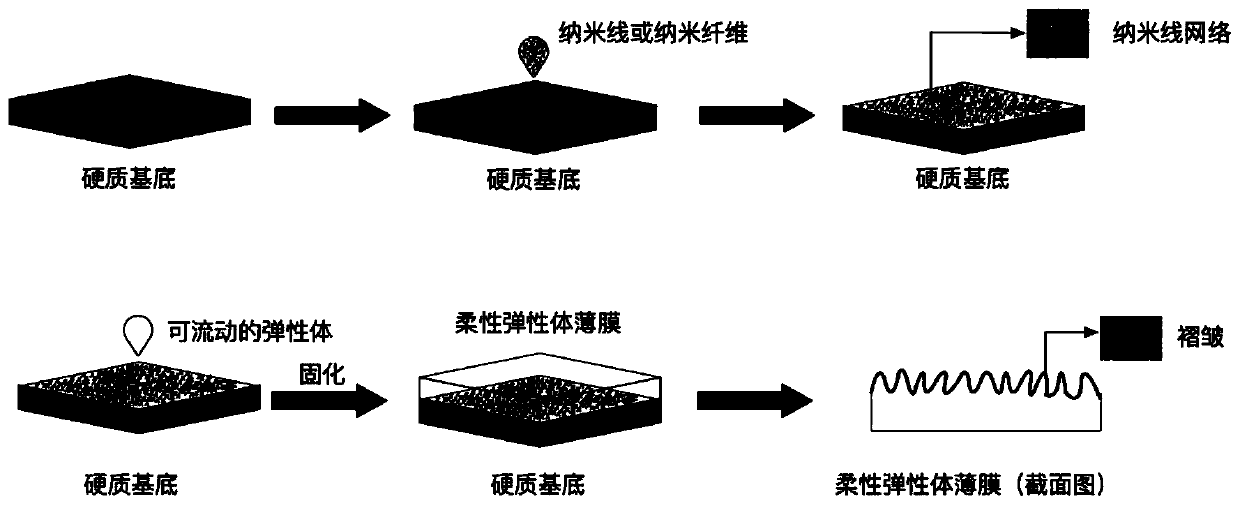

[0043] This embodiment provides a method for forming nano-folds on the surface of an elastomer film, comprising the steps of:

[0044] S10, the slides were ultrasonically cleaned in acetone, alcohol, and deionized water in sequence, then rinsed with deionized water and dried with nitrogen; then, the slides were bombarded with oxygen plasma for 5 to 10 minutes to obtain a Water-based hard substrate.

[0045] Specifically, the size of the slide is 2.0 cm (length) x 1.0 cm (width) x 0.1 cm (height);

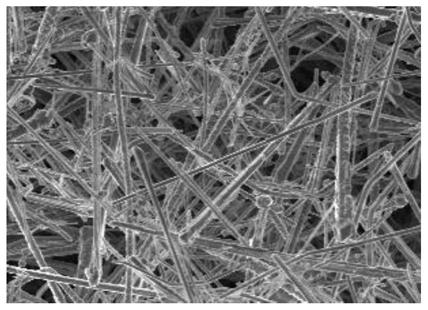

[0046] S11, forming a nanowire network with a dense structure on the surface of the hard substrate by drip-coating the copper nanowire solution multiple times, in the nanowire network, the nanowires are criss-crossed and overlapped up and down, and there are void.

[0047] Specifically, copper nanowires with a diameter of 50-200 nanometers and a length of 1-10 microns are dissolved in alcohol to form a copper nanowire solution with good monodispersity (mass fraction is 0.01wt.%); ...

Embodiment 2

[0054] This embodiment provides a method for forming nano-folds on the surface of an elastomer film, comprising the steps of:

[0055] S20, the slides were ultrasonically cleaned in acetone, alcohol, and deionized water in sequence, then rinsed with deionized water and dried with nitrogen; then, the slides were bombarded with oxygen plasma for 5 to 10 minutes to obtain a Water-based hard substrate.

[0056] Specifically, the size of the slide is 2.0 cm (length) x 1.0 cm (width) x 0.1 cm (height);

[0057] S21, forming a nanowire network with a dense structure on the surface of the hard substrate by drip-coating the copper nanowire solution multiple times, in the nanowire network, the nanowires are criss-crossed and overlapped up and down, and there are void.

[0058] Specifically, copper nanowires with a diameter of 50-200 nanometers and a length of 1-10 microns are dissolved in alcohol to form a copper nanowire solution with good monodispersity (mass fraction is 0.01wt.%); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com