Injectable composite material capable of promoting bone regeneration and repair and preparation method thereof

A composite material and bone regeneration technology, applied in the field of biomedical materials and regenerative medicine, can solve the problems of unsatisfactory osteoporotic fractures, difficult matching of degradation rate, poor biological activity, etc., to facilitate the transmission of nutrients and optimize biological Activity, promoting effect of cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

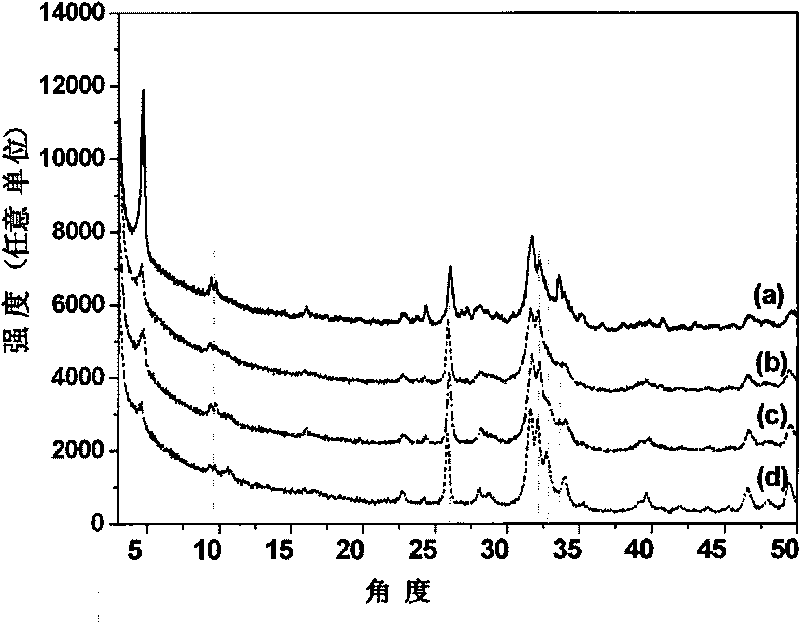

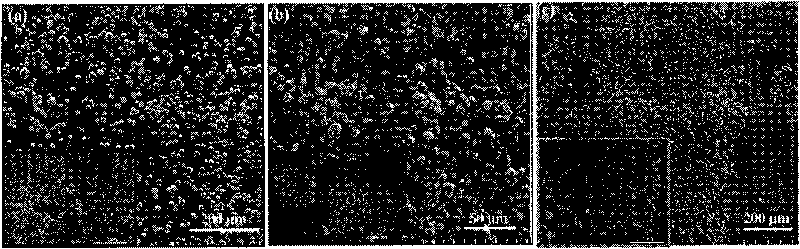

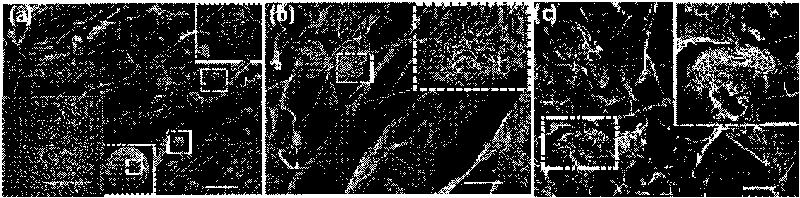

[0050] 1) Will contain SiO 3 2- , PO 4 3- Na 2 SiO 3 And Na 3 PO 4 The molar ratio of the inorganic salt is 1:10 and added to the sodium polyaspartate aqueous solution to control the sodium phosphate concentration to 10%, maintain the mixed solution at 37°C, and adjust the pH of the solution with hydrochloric acid under continuous conditions 7.0, continuous stirring to form a uniform solution, and then the Ca 2+ , Sr 2+ , Zn 2+ And Mg 2+ Ionic Ca(CH 3 COO) 2 ·H 2 O, SrCl 2 , ZnCl 2 And MgCl 2 The solution is added dropwise to the sodium phosphate mixed solution, Ca 2+ , Sr 2+ , Zn 2+ And Mg 2+ Total moles and SiO 3 2- And PO 4 3- The ratio of the total number of moles is 8:6. After the addition is complete, maintain the temperature of the solution and continue stirring and aging for 10 minutes, then stop stirring and filter to precipitate the multi-element co-doped calcium phosphate microspheres, and use deionized water and anhydrous Washed with ethanol 3 times, then filtered and...

Embodiment 2

[0056] The preparation method is the same as in Example 1, the difference is: Step 1) will contain PO 4 3- Na 2 HPO 4 ·2H 2 The molar ratio of O inorganic salt is 1:10 and added to the sodium polyacrylate aqueous solution, the sodium phosphate concentration is controlled to 10%, the mixed solution is maintained at 60°C, and the pH of the solution is adjusted to 4.8 with hydrochloric acid under continuous conditions. Stir continuously to form a uniform solution, and then add Ca 2+ , Sr 2+ , Zn 2+ And Mg 2+ Ion of CaCl 2 , SrCl 2 , ZnCl 2 And MgCl 2 The solution is added dropwise to the sodium phosphate mixed solution, Ca 2+ , Sr 2+ , Zn 2+ And Mg 2+ Total moles and PO 4 3- The ratio of the mole number of phosphate is 8:6. After the addition, the temperature of the solution is maintained and the octacalcium phosphate microsphere particles are partially transformed, and the hydroxyapatite and octacalcium phosphate composite with a slower degradation rate are obtained by maintaining t...

Embodiment 3

[0059] The preparation method is the same as in Example 1, the difference is: Step 1) will contain PO 4 3- Na 3 PO 4 Add the sodium polyacrylate aqueous solution at a molar ratio of 1:10, control the sodium phosphate concentration to 10%, maintain the mixed solution at 40°C, and adjust the pH of the solution to 6.8 with hydrochloric acid under continuous conditions, and continue stirring to form Homogeneous solution, then add Ca 2+ , Zn 2+ And Mg 2+ Ion of CaCl 2 , Zn(NO3) 2 And MgCl 2 The solution is added dropwise to the sodium phosphate mixed solution, Ca 2+ , Zn 2+ And Mg 2+ Total moles and PO 4 3- The ratio of the number of moles is 8:6. After the addition, the temperature of the solution is maintained and the solution is continuously stirred and aged for 360 minutes. The octacalcium phosphate microsphere particles are transformed to obtain hydroxyapatite microspheres with a slower degradation rate. Wash with water and absolute ethanol three times in sequence, then filter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com