Method for degrading organic matters in water by activated persulfate coupling system

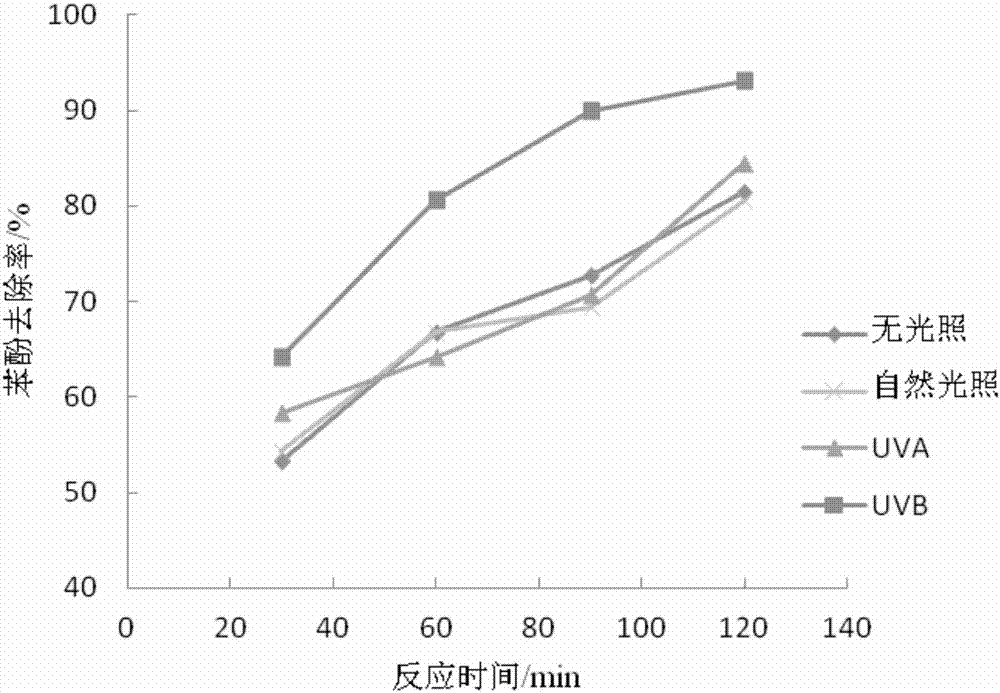

A technology for activating persulfate and persulfate, which is applied in chemical instruments and methods, water pollutants, chemical/physical processes, etc., can solve problems such as catalyst recovery difficulties and environmental secondary pollution, and achieve enhanced organic degradation effects, The effect of low metal ion dissolution and improved photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

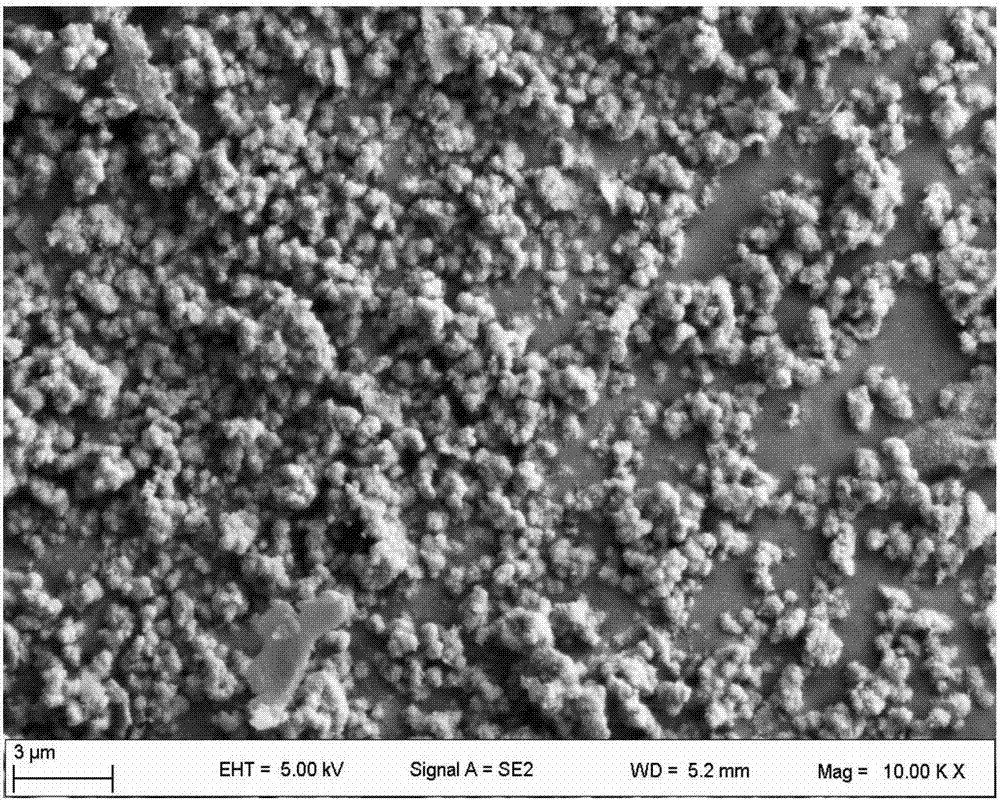

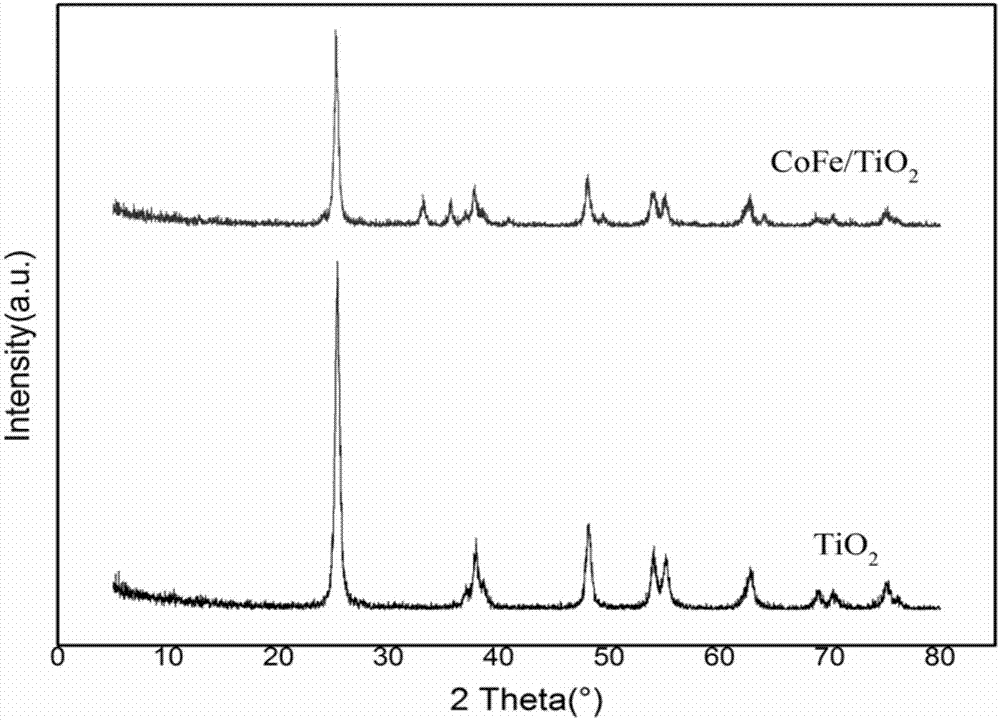

[0025] (1) Thoroughly mix 25mL tetrabutyl titanate and 32.2mL absolute ethanol. Take another 32.2mL of absolute ethanol, adjust the pH to 2-3 with hydrochloric acid, add it to the above-mentioned mixture of tetrabutyl titanate and absolute ethanol, and stir it for 30 minutes to make it fully mixed to obtain TiO 2 Sol.

[0026] (2) Take 80mL TiO 2 After mixing the sol with 12g phenol, add it to 100mL n-heptane dispersion medium, add dropwise 16mL formaldehyde under full stirring, heat up to 60-70°C for reaction, filter the mixture after about 1.5h, and wash it repeatedly with ethanol, Obtain a milky white polymer, which is TiO 2 Composite microspheres are dried and roasted at 500°C for 2 hours to decompose the polymer to obtain TiO 2 porous microspheres.

[0027] (3) Prepare 50mL of Co(NO 3 ) 2 ·6H 2 O and 0.125mol / L Fe(NO 3 ) 3 9H 2 O precursor mixed solution, 1g TiO 2 Immerse it in it, stir it electromagnetically for 5 hours, then stir it in a water bath at 80°C an...

Embodiment 2

[0030] (1) Thoroughly mix 12.5 mL of tetrabutyl titanate and 16.1 mL of absolute ethanol. Take another 16.1mL of absolute ethanol, adjust the pH to 2-3 with hydrochloric acid, add it to the above-mentioned mixture of tetrabutyl titanate and absolute ethanol, and stir it for 30 minutes to make it fully mixed to obtain TiO 2 Sol.

[0031] (2) Take 40mL TiO 2 After mixing the sol with 6g of phenol, add it to 50mL of n-heptane dispersion medium, add 8mL of formaldehyde dropwise under sufficient stirring, heat up to 60-70°C for reaction, filter the mixed solution after about 1.5h, and wash it repeatedly with ethanol, The milky white polymer is TiO 2 Composite microspheres are dried and roasted at 500°C for 2 hours to decompose the polymer to obtain TiO2 porous microspheres.

[0032] (3) Prepare 25 mL of Co(NO 3 ) 2 ·6H 2 O and 0.125mol / L Fe(NO 3 ) 3 9H 2 O precursor mixed solution, 0.5g TiO 2 Immerse it in it, stir it electromagnetically for 5 hours, then stir it in a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com