Porous carbon microsphere with surface covered with graphene, and preparing method and application of porous carbon microsphere

A technology of porous microspheres and porous carbon, applied in the field of material science, can solve problems such as electrical performance and stability to be improved, limit the application of graphene, irreversible agglomeration, etc., and achieve industrialized large-scale production, excellent electrical conductivity, and controllable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

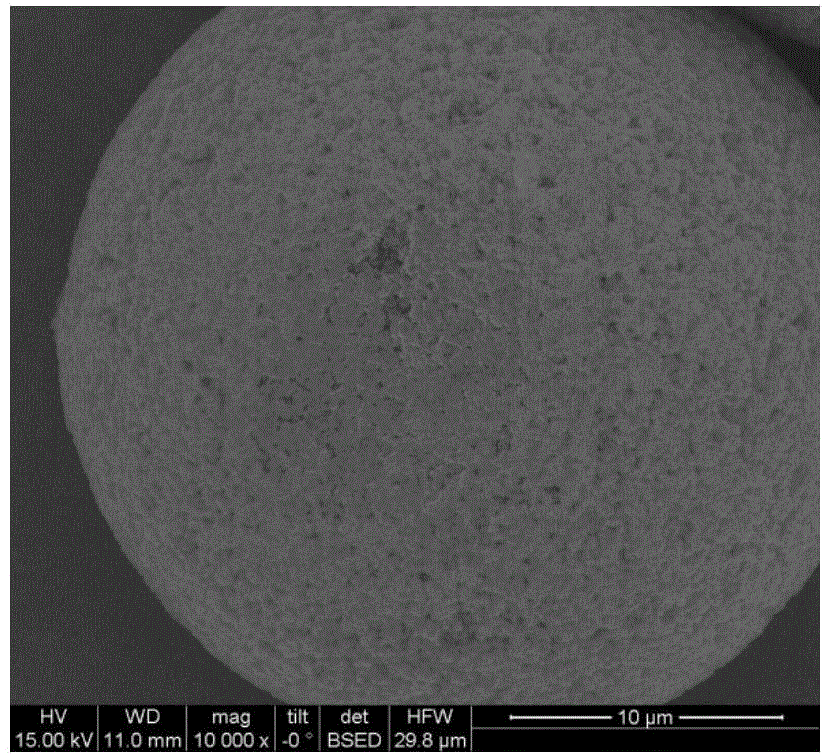

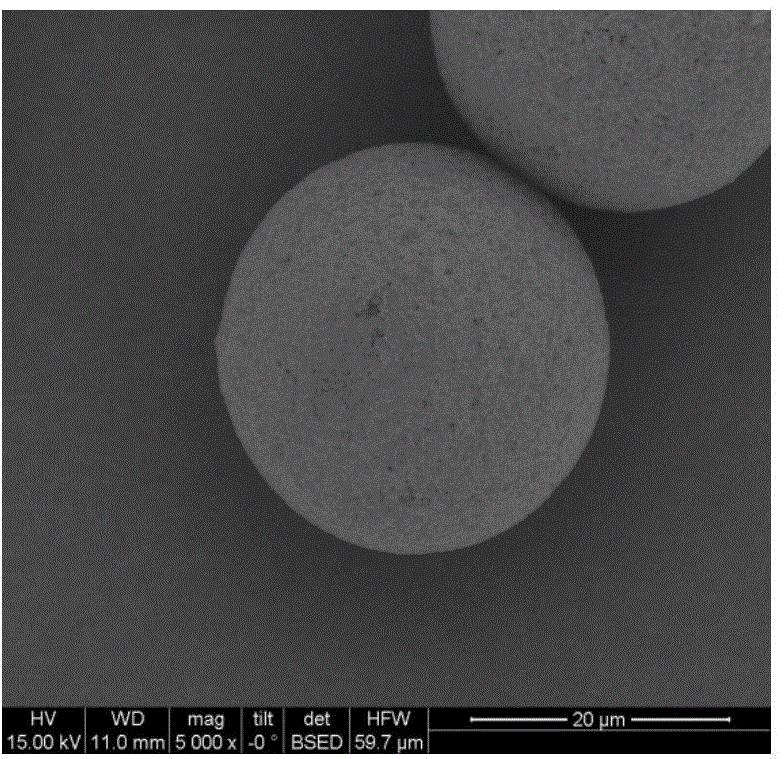

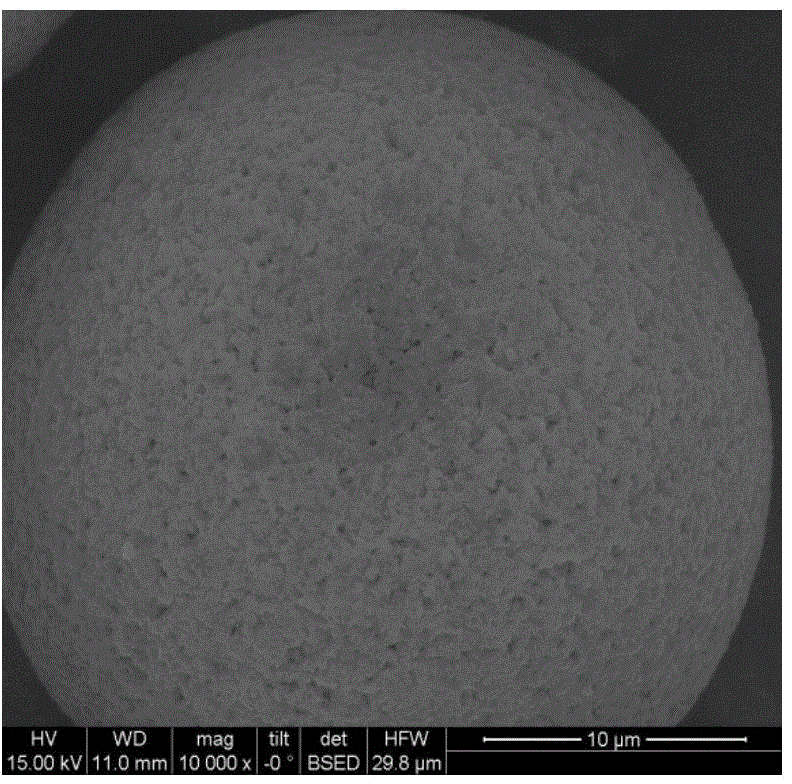

[0028] Aminated polyacrylate microspheres with an average particle size of about 30 μm and quaternary amine groups attached to the surface (Suzhou Nawei Technology Co., Ltd., product model UniQ-30L, please refer to Figure 1a-Figure 1b , surface porous and no bonding phenomenon) as a template, uniformly dispersed in the concentration of 5% (wt) sulfonated graphene (diameter thickness of about 3-5 nanometers, can refer to CN103539105A; CN103359728A; Nano Letters, 2008,8 ( 6): 1679–1682 and other documents, which can also be obtained through commercial channels) in aqueous solution, after continuous stirring and soaking for 2 hours, put it in a constant temperature drying oven, and dry it at 60°C for 24 hours to obtain the dried product, namely Polymer porous microspheres / graphene composites (polymer porous microspheres coated with sulfonated graphene on the surface, please refer to Figure 2a-Figure 2b , the porous structure can be seen and there is no bonding phenomenon), and t...

Embodiment 2

[0032] Aminated polystyrene microspheres with an average particle size of about 100 μm and quaternary amine groups attached to the surface (Suzhou Nanomicro Technology Co., Ltd., product model PS1100) were used as templates and uniformly dispersed in sulfonated graphene with a concentration of 10 wt%. Water ((diameter and thickness about 3-5nm) solution, after continuous stirring and soaking for 2 hours, put it in a constant temperature drying oven, and dry it at 80°C for 48 hours to obtain the product after drying, that is, polymer porous microspheres / graphene Afterwards, put the dried product in a nitrogen atmosphere, raise the temperature to about 1200°C at a rate of 10°C / m / / , and carbonize at a high temperature for 2 hours to obtain the target product, that is, porous carbon microspheres coated with graphene on the surface , its diameter is about 70 μ m, and has porous structure (aperture about 35 / m), and graphene is covered on the surface of porous carbon microspheres. Thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com