Nano titanium dioxide porous microsphere and its production method

A nano-titanium dioxide, manufacturing method technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical process and other directions, can solve problems such as cost increase, bulky, complex photocatalyst separation, etc., to simplify the structure and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

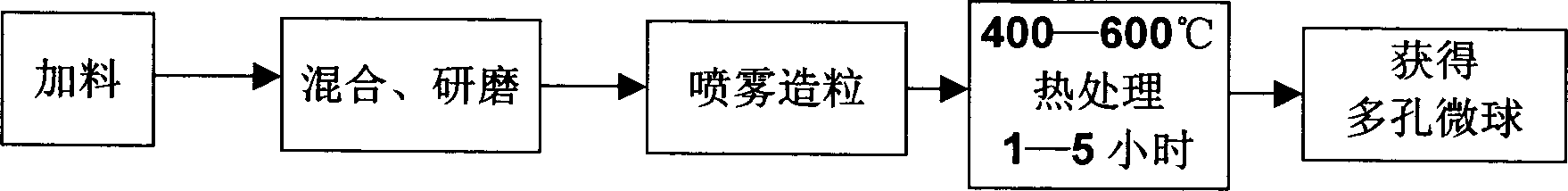

[0024] Embodiment one: see attached figure 1 Shown, a kind of manufacture method of nano-titanium dioxide porous microsphere, 30% nano-titanium dioxide powder (20-25 nanometer), 65% nano-titanium dioxide colloid (15-20 nanometer) and 5% Tween mix, grind, A mixed slurry of nano-titanium dioxide is obtained; spray granulation is adopted; heat treatment is performed at 400° C. for 3 hours to obtain nano-titanium dioxide porous microspheres.

[0025] The technical index of the nano titanium dioxide porous microsphere that present embodiment obtains is:

[0026] Titanium dioxide content: >99.0%

[0027] Crystal form: 100% anatase phase

[0028] Appearance: off-white

[0029] Granular particle size: 60 mesh to 150 mesh (250μm-100μm)

[0030] Loose bulk density: about 0.8 g / cm 3

[0031] Specific surface area: about 80m2 / g-100m2 / g

[0032] Pore volume: 0.38-0.40cc / g

[0033] Pore size: 20nm to 80nm

[0034] Absorb UV wavelength: λ<380nm, 100% absorption

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com