Chitosan/sheet silicate nano compound stephanoporate crosslinked microsphere sorbent and preparation method thereof

A layered silicate, cross-linked microsphere technology, applied in silicon compounds, chemical instruments and methods, other chemical processes, etc., can solve problems such as the difficulty of desorption and recovery of heavy metal substances, and achieve the improvement of adsorption process and recovery process, The effect of expanding the scope of application and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

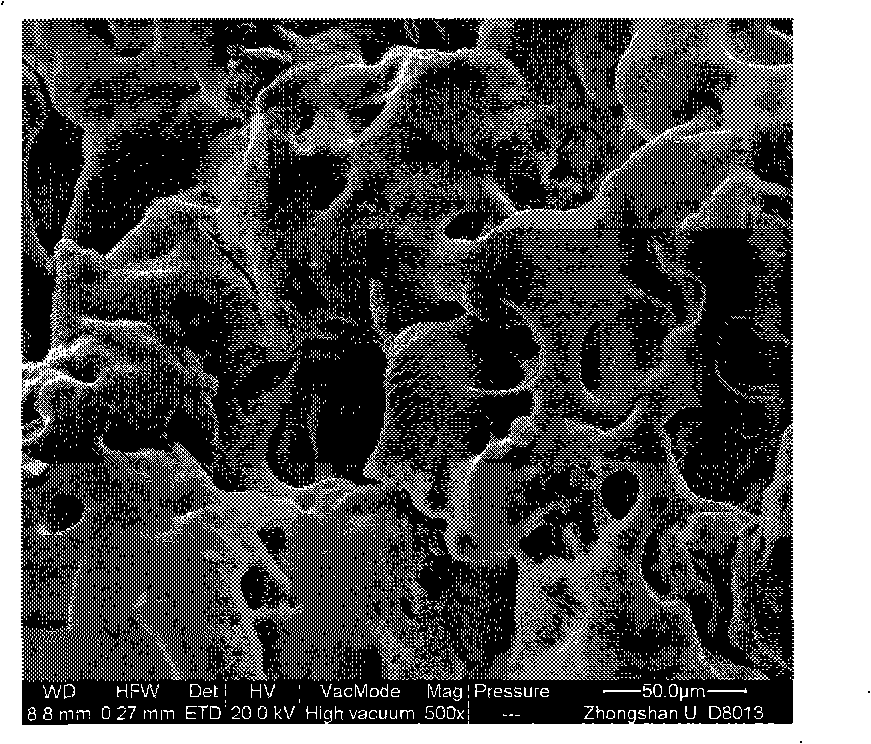

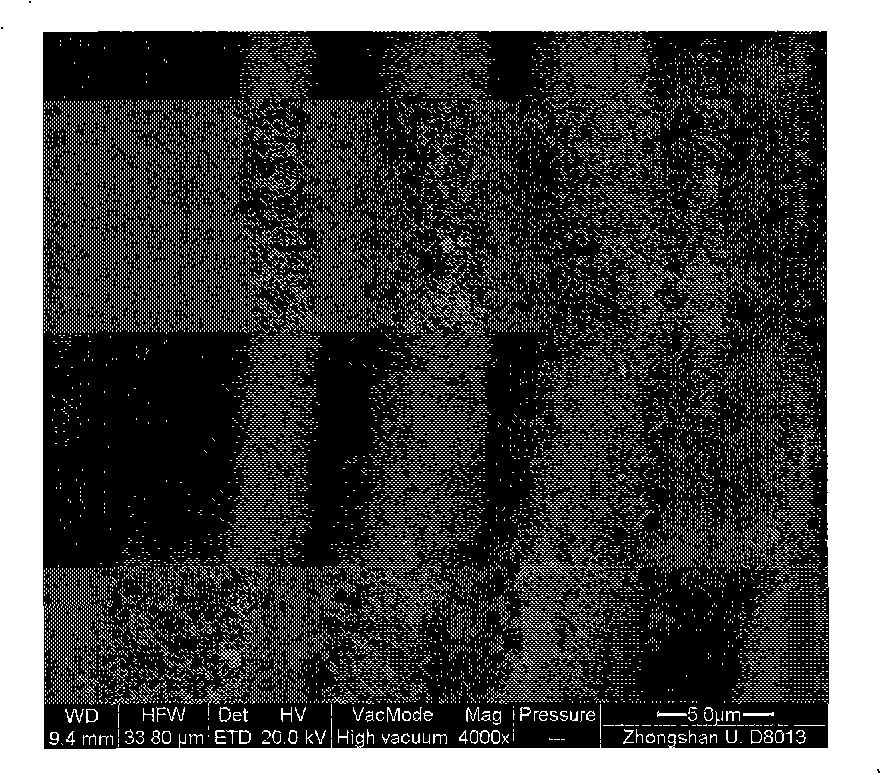

[0042] This embodiment provides a method for preparing a porous microsphere adsorbent that has high-efficiency adsorption and separation capabilities for heavy metal ions and organic pollutants and is inexpensive, which specifically includes the following steps:

[0043] (1) Preparation of phyllosilicate suspension: add 100 to 500 parts by weight of water to 1 to 20 parts by weight of phyllosilicate, and stir at a temperature of 50 to 95° C. for 1 to 6 hours to obtain a suspension of phyllosilicate. suspension;

[0044] (2) Preparation of low molecular weight chitosan solution: 1~20 parts by weight of low molecular weight chitosan is dissolved in 100~500 parts by weight of concentration in the acidic solution of 1~8% (volume ratio), adjust the pH value to 3~ 6, obtain chitosan acidic solution;

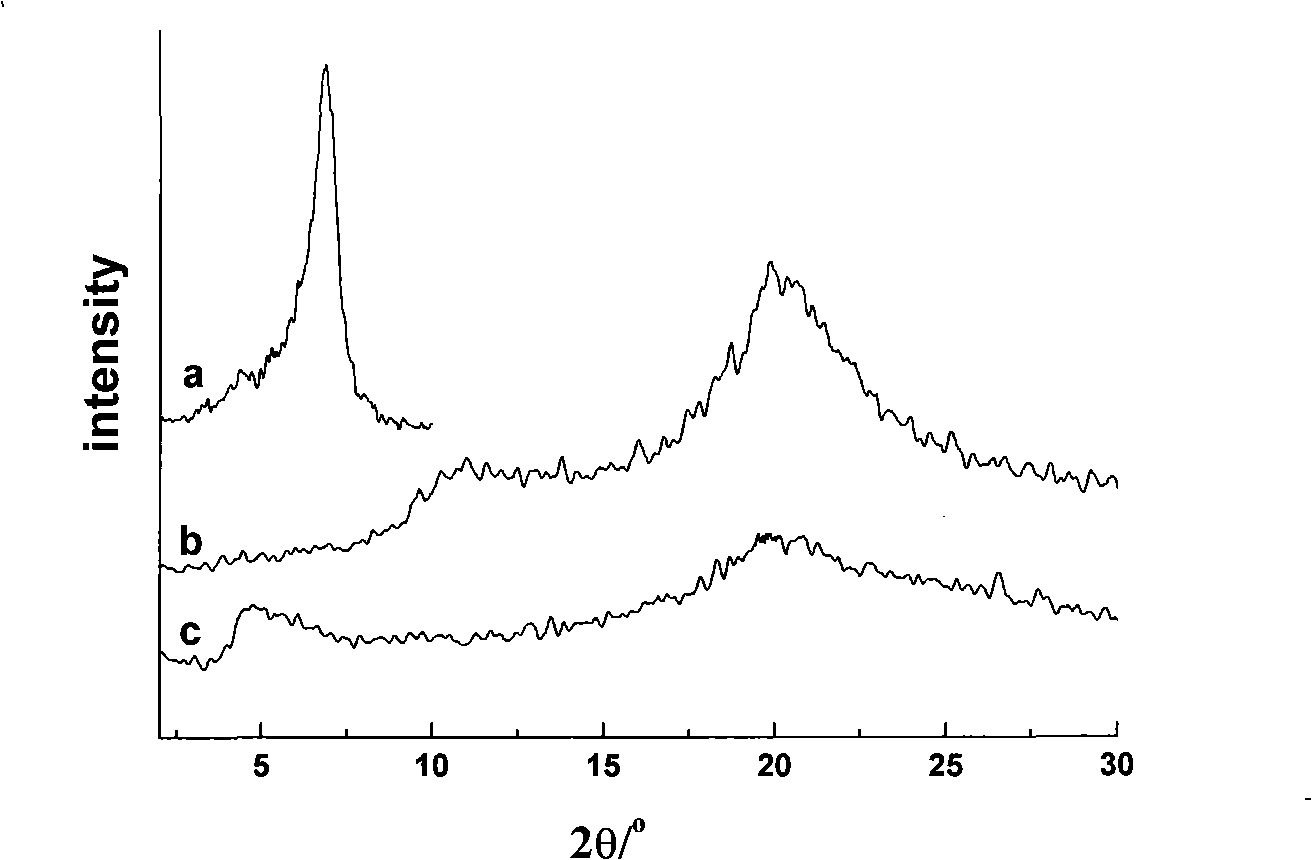

[0045] (3) Preparation of chitosan / layered silicate intercalation complex: the layered silicate suspension obtained in the above (1) and the chitosan obtained in the above (2) The ac...

Embodiment 2

[0064] The present embodiment provides a kind of preparation method of chitosan / phyllosilicate nanocomposite porous crosslinked microsphere adsorbent, specifically comprises the following steps:

[0065] (1) Add 5 g of montmorillonite to 150 ml of deionized water, and stir for 6 hours at a temperature of 50° C. to obtain a suspension of montmorillonite;

[0066] (2) mix with the montmorillonite suspension with chitosan acetic acid solution with the same volume as the montmorillonite suspension, the molecular weight is 27,000, the degree of deacetylation is 94.2%, and the concentration is 3% (wt%), adjusting the pH value of the mixed solution to 3.8; stirring at a temperature of 40° C. for 8 hours to obtain a chitosan / montmorillonite intercalation complex solution;

[0067] (3) Weigh 4.8g of chitosan with a molecular weight of 710,000 and a degree of deacetylation of 92.3, dissolve it in the compound solution in (2) above, stir at 50°C for 5 hours, cool to room temperature and ...

Embodiment 3

[0072] The present embodiment provides a preparation method of chitosan / layered silicate nanocomposite porous crosslinked microsphere adsorbent, which is specifically carried out according to the following steps:

[0073] (1) Add 4 g of kaolin to 125 ml of deionized water, and stir for 5 hours at a temperature of 60° C. to obtain a kaolin suspension;

[0074] (2) the chitosan acetic acid solution that is 27,000, the degree of deacetylation is 95.2%, and the concentration is 2% (wt%) is mixed with the kaolin suspension with the molecular weight of the same volume as the kaolin suspension, and the pH value of the adjustment is 4.8, stirring at a temperature of 50° C. for 6 hours to obtain a chitosan / kaolin intercalation complex solution;

[0075] (3) Take by weighing 3.8g, molecular weight is 650,000, the chitosan that deacetylation degree is 91.3 is dissolved in the described complex solution that makes in above-mentioned (2), after stirring 4 hours at 60 ℃ of temperature, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com