Preparation method of composite porous microspheres of core-shell structure

A technology of porous microsphere and core-shell structure, which is applied in the direction of medical preparations, microcapsules, and pharmaceutical formulations of non-active ingredients. Problems such as lumps, to achieve the effects of drug loading, good dispersion, and improved slow release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. 50mL petroleum ether + 2.4g Span80 + 10mL 0.5wt% sodium alginate solution, emulsified for 1 hour to obtain a water-in-oil emulsion;

[0033] 2. Add 20 mg of chitosan microspheres to the water-in-oil emulsion, stir for 1 hour, let it interact with the sodium alginate in the milk droplet to generate electrostatic attraction, and adsorb on the surface of chitosan porous microspheres;

[0034] 3. After ultrasonically dispersing the emulsion obtained in step 2 for 5min, add 50mL of ethanol, and suction filter to obtain porous chitosan microspheres coated with sodium alginate;

[0035] 4. Put the obtained microspheres into 20mL 2wt% calcium chloride solution and cross-link for 1h to obtain the calcium alginate shell;

[0036] 5. Wash the microspheres obtained in step 4, wash them with distilled water several times, and dry them in vacuum to obtain calcium alginate gel layer-coated porous chitosan composite porous microspheres.

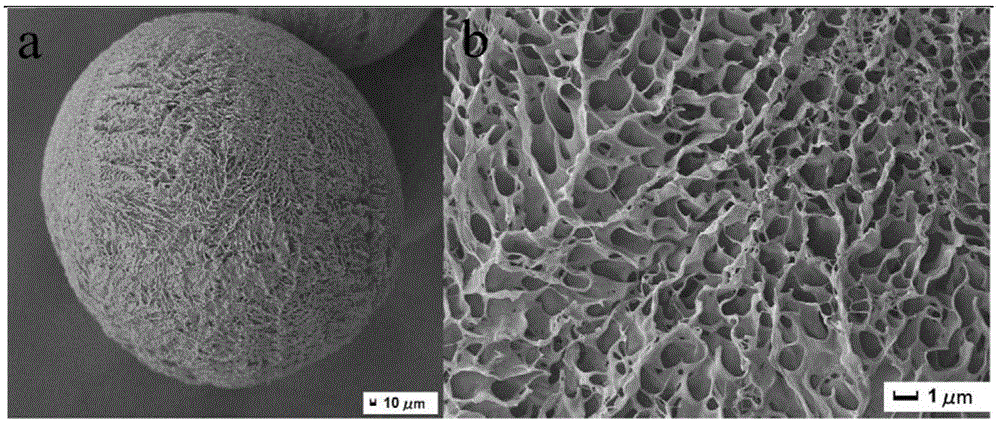

[0037] The scanning electron micrographs of...

Embodiment 2

[0041] 1. 50mL of petroleum ether + 3.2g of Span80 + 8mL of 1wt% polyvinyl alcohol solution, emulsified for 2 hours to obtain a water-in-oil emulsion;

[0042] 2. Add 20 mg chitosan microspheres to the water-in-oil emulsion, stir for 1 hour, let it interact with the polyvinyl alcohol in the emulsion droplet to undergo hydrogen bond interaction, and adsorb on the surface of the chitosan porous microspheres;

[0043] 3. After ultrasonic dispersion of the emulsion obtained in step 2 for 5min, add 50mL of ethanol, and obtain the porous chitosan microspheres coated with polyvinyl alcohol by suction filtration;

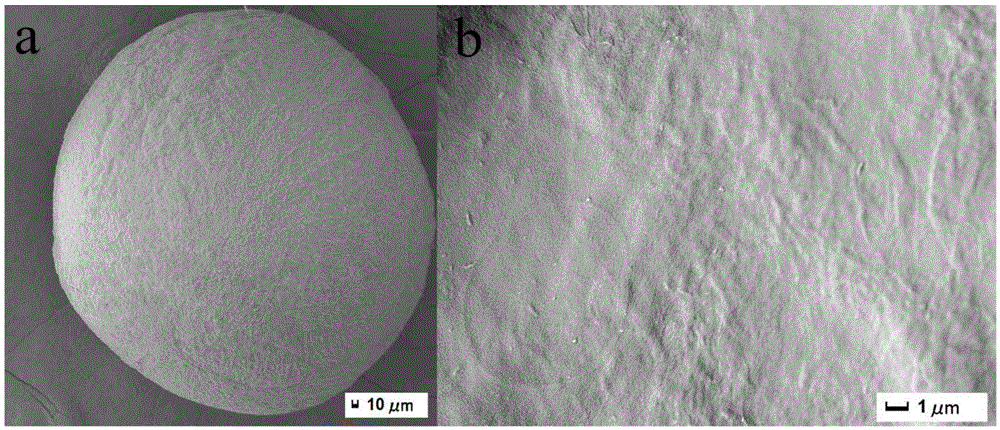

[0044] 4. The microspheres obtained in step 4 are washed with ethanol, and vacuum-dried to obtain porous chitosan composite porous microspheres coated with polyvinyl alcohol shells.

Embodiment 3

[0046] 1. 50mL paraffin oil+2gSpan80+10mL1wt% cellulose solution, emulsified for 1.5h to obtain a water-in-oil emulsion;

[0047] 2. Add 20 mg chitosan microspheres to the water-in-oil emulsion, stir for 1 hour, let it interact with the cellulose in the emulsion droplets, and adsorb on the surface of chitosan porous microspheres;

[0048] 3. After ultrasonically dispersing the emulsion obtained in step 2 for 5min, add 50mL of acetone, and obtain the porous chitosan microspheres coated with cellulose by suction filtration;

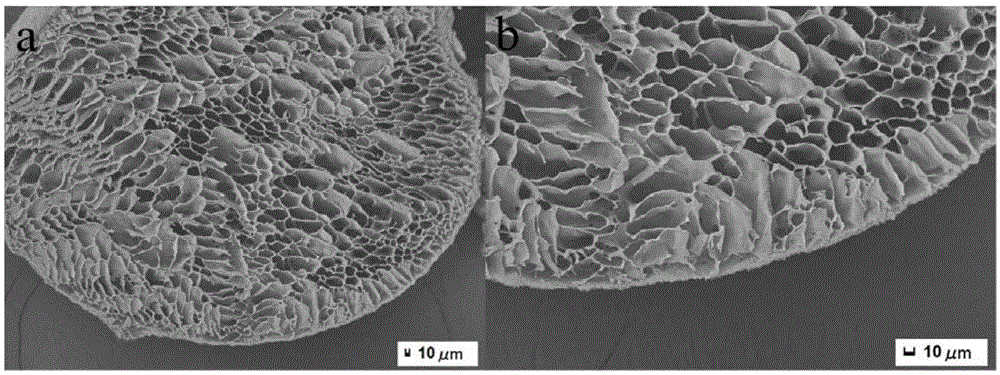

[0049] 4. Wash the microspheres obtained in step 4, wash them with acetone several times, and dry them in vacuum to obtain porous chitosan composite porous microspheres coated with cellulose shells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com