Method for preparing magnetic porous polystyrene microspheres on basis of suspension polymerization

A technology of porous polystyrene and suspension polymerization, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of difficult separation of adsorption materials, and achieve rapid separation and good magnetic response Properties, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. A method for preparing magnetic porous polystyrene microspheres by suspension polymerization, the preparation method is carried out according to the following steps:

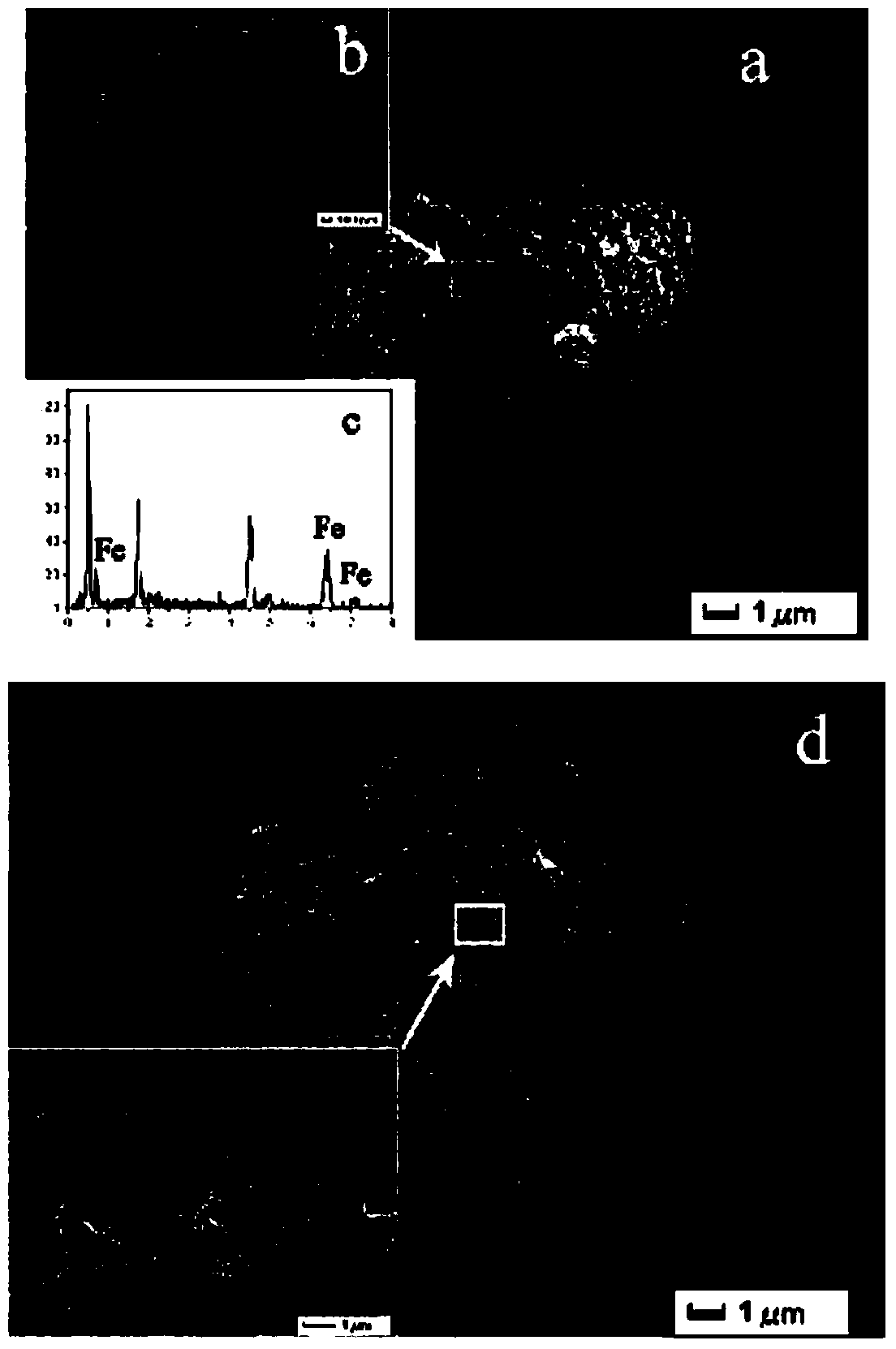

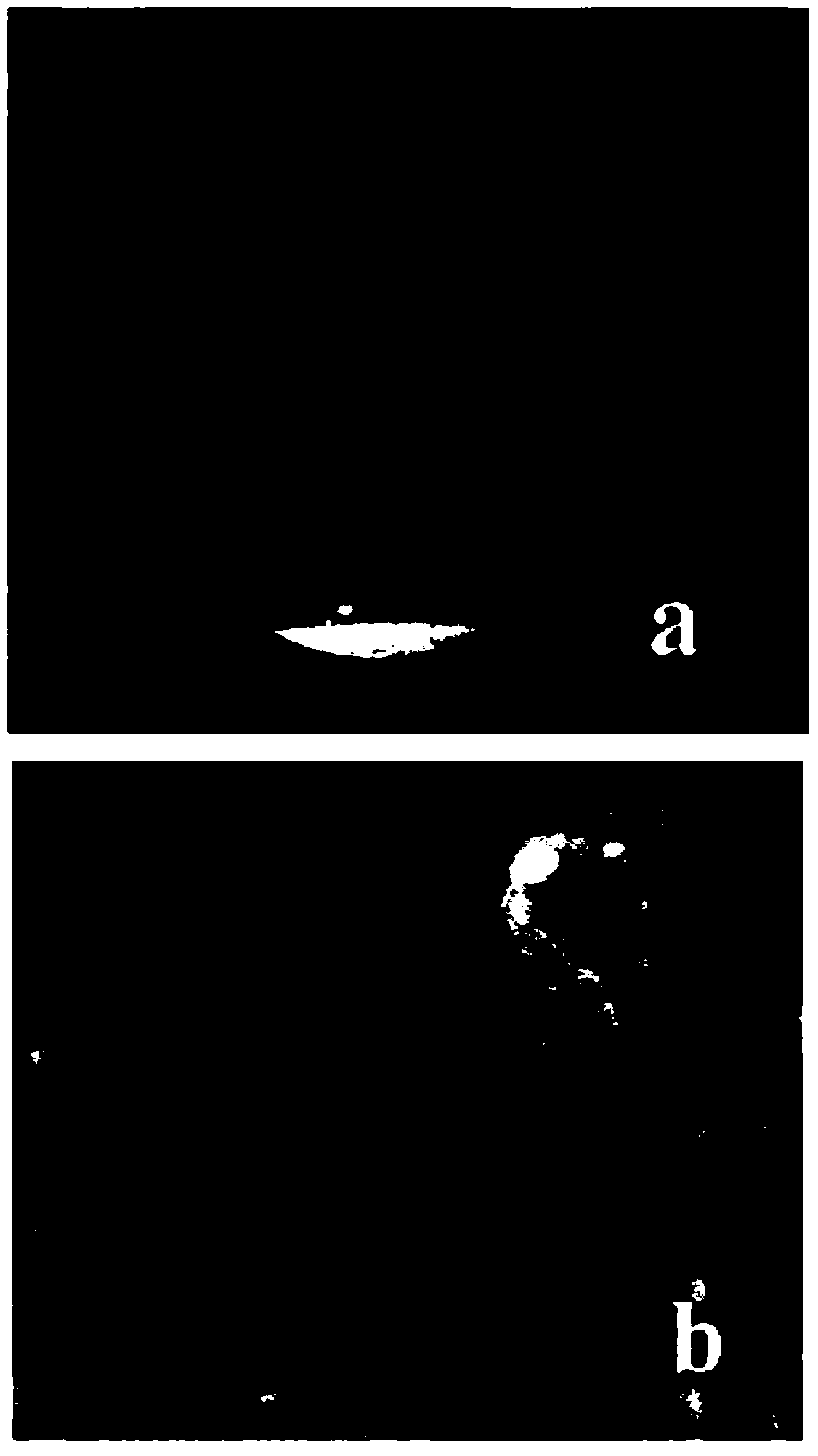

[0037] (1) Solvothermal synthesis of ferric oxide (Fe 3 o 4 ) magnetic nanoparticles:

[0038] 1.35 g ferric chloride hexahydrate (FeCl 3 ·6H 2 (0) and 7.2 g of sodium acetate (NaAc) were dissolved in 40 ml of ethylene glycol solution, and the mixed solution was stirred in a constant temperature water bath at 160° C. for 1 h at a speed of 800 rpm / min under the protection of nitrogen, and then the mixed solution was transferred to 50 ml In a reaction kettle, react at 200°C for 10h, cool to room temperature, wash the suspension three times with ethanol solution, dry the obtained product in a vacuum environment of 60°C, and finally grind it in a mortar, Get Fe 3 o 4 Nanoparticles.

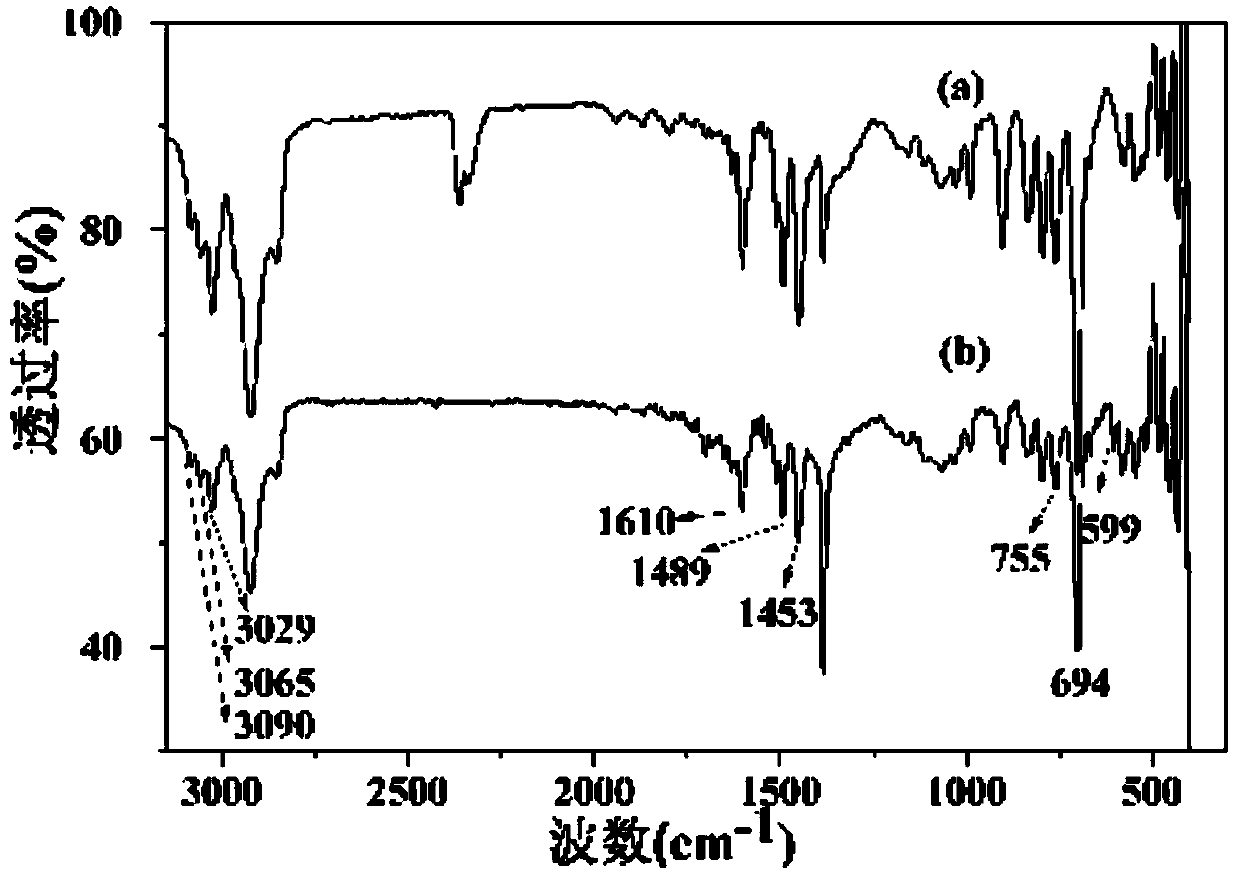

[0039] (2) Oleic acid on Fe 3 o 4 Magnetic nanoparticles for surface modification

[0040] 4 ml oleic acid was add...

Embodiment 2

[0055] 1. A method for preparing magnetic porous adsorbent by suspension polymerization, the preparation method is carried out according to the following steps:

[0056] (1) Synthesis of Fe3O4 magnetic nanoparticles by solvothermal method:

[0057] 1.85 g ferric chloride hexahydrate (FeCl 3 ·6H 2 (0) and 7.3 g of sodium acetate (NaAc) were dissolved in 45 ml of ethylene glycol solution, and the mixed solution was stirred in a constant temperature water bath at 160° C. for 2 h at a speed of 800 rpm / min under the protection of nitrogen, and then the mixed solution was transferred to 50 ml React in a reaction kettle at 200°C for 12 hours, cool to room temperature, wash the suspension 5 times with ethanol solution, dry the obtained product in a vacuum environment at 60°C, and finally crush and grind it in a mortar to obtain Fe 3 o 4 Nanoparticles.

[0058] (2) Oleic acid on Fe 3 o 4 Magnetic nanoparticles for surface modification

[0059] 4 ml oleic acid was added to 0.1 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com