Preparation method of alumina porous microsphere

A technology of porous microspheres and alumina, applied in alumina/aluminum hydroxide and other directions, can solve the problems of complex process and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

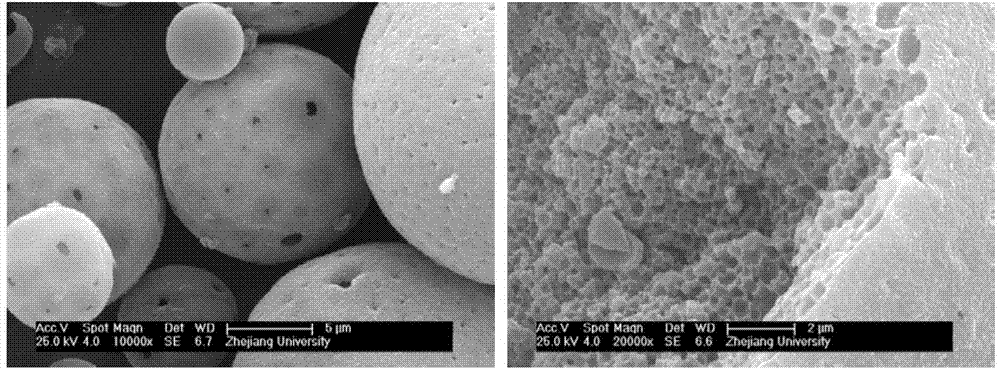

Image

Examples

Embodiment 1

[0030] Embodiment 1, a kind of preparation method of aluminum oxide porous microsphere, carries out following steps successively:

[0031] 1) Dissolve 4g of sodium lauryl sulfate and 8g of OP-10 in 300g of deionized water, and continuously stir in a high-speed disperser at 1000 rpm for 60 minutes; as the water required for the emulsion method Mutually.

[0032] 2) Mix 2.377g of ethyl acetoacetate, 4.450g of aluminum sec-butoxide and 10.450g of n-octanol, and stir (1000 rpm) for 1 hour, as the oil phase required by the emulsion method.

[0033] 3) Add 0.571g Span80 and 0.571g polyvinylpyrrolidone to the oil phase obtained in step 2), and continue stirring (1000 rpm) for 1 hour to obtain a uniform and clear oil phase.

[0034] 4) Pour the obtained clear oil phase solution into the water phase in the high-speed disperser, and keep stirring (1000 rpm) for emulsification for 24 hours.

[0035] The above steps 1) to 4) are all carried out at room temperature.

[0036] 5) After va...

Embodiment 2

[0039] Change "4g sodium lauryl sulfate and 8g OP-10" in embodiment 1 into "12g sodium lauryl sulfate", and the rest are the same as embodiment 1.

[0040] The size of the obtained aluminum oxide porous microsphere is 1-3 μm, the inside of the microsphere is a closed pore structure, and the diameter of the closed pores is 300 nm-1 μm.

Embodiment 3

[0042] Change "4g sodium lauryl sulfate and 8g OP-10" into "12g of OP-10" in Example 1, and the rest are the same as Example 1.

[0043] The size of the obtained aluminum oxide porous microsphere is 5-50 μm, the inside of the microsphere is a closed pore structure, and the diameter of the closed pore is 50nm-800nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com