Preparation method of porous chitosan-based microspheres

A technology of porous microspheres and chitosan, which is applied to the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of increased environmental burden, consumption of raw materials, and complicated processes, so as to avoid biological toxicity and save raw materials , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of embodiment 1 chitosan porous microspheres comprises the steps:

[0040] 1. Dissolve 1 g of chitosan in 100 mL of 1 wt % acetic acid aqueous solution, and remove foam.

[0041] 2. Dissolve 5g of Span 80 in 100mL petroleum ether solution.

[0042] 3. Take 10 mL of the chitosan solution obtained in step 1 as a dispersed phase and slowly add it to the continuous phase solution obtained in step 2, and stir at a high speed to obtain an emulsion.

[0043] 4. Place the emulsion in a freezer at -20°C for 4 hours to freeze and quench.

[0044] 5. Pour the mixed coagulation solution of 1wt% NaOH ethanol water at -20°C into the quenched emulsion and soak for 3 hours.

[0045] 6. Centrifuge to obtain chitosan microspheres, wash with ethanol and water for several times and then dry to obtain the product.

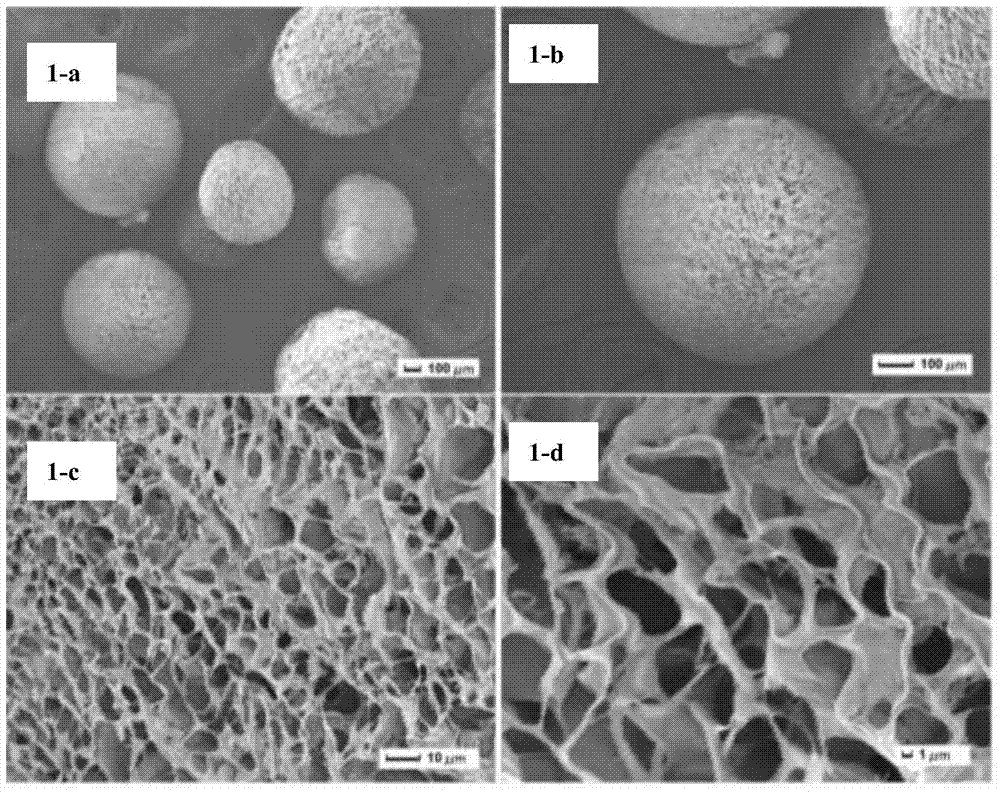

[0046] The chitosan microspheres that present embodiment prepares, its size and surface morphology are as follows figure 1 As shown, the size of th...

Embodiment 2

[0047] The preparation method of embodiment 2 chitosan / PVA porous microspheres comprises the steps:

[0048] 1. Dissolve 0.5g chitosan and 0.5g PVA in 100mL of 1wt% acetic acid aqueous solution, and defoam.

[0049] 2. Dissolve 5g of Span 80 in 100mL petroleum ether solution.

[0050] 3. Take 10 mL of the mixed solution obtained in step 1 as the dispersed phase and slowly add it to the continuous phase solution obtained in step 2, and stir at high speed to obtain an emulsion.

[0051] 4. Place the emulsion in a freezer at -20°C for 4 hours to freeze and quench.

[0052] 5. Pour the mixed coagulation solution of 1wt% NaOH ethanol water at -20°C into the quenched emulsion and soak for 3 hours.

[0053] 6. Centrifuge to obtain chitosan / PVA composite microspheres, wash with ethanol and water for several times and then dry to obtain the product.

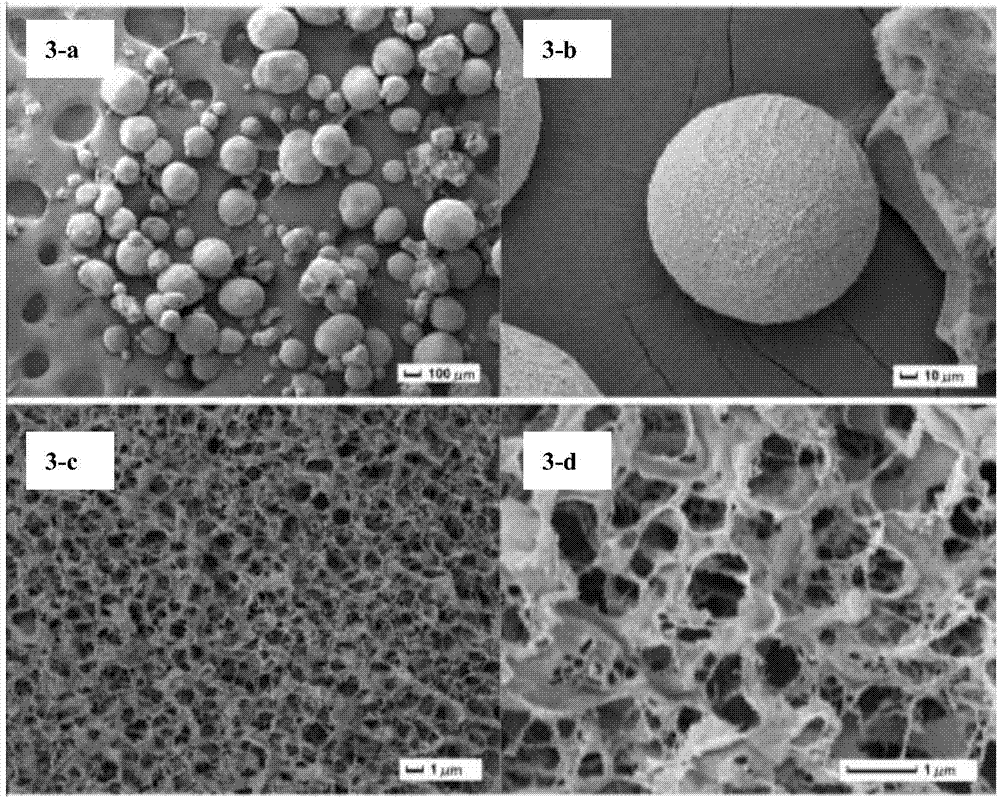

[0054] The chitosan / PVA composite microsphere that present embodiment prepares, its appearance is as follows image 3 As shown, th...

Embodiment 3

[0055] The preparation method of embodiment 3 chitosan / gelatin porous microspheres comprises the steps:

[0056] 1. Dissolve 0.5 g chitosan and 0.5 g gelatin in 100 mL of 1 wt % acetic acid aqueous solution, and defoam.

[0057] 2. Dissolve 5g of Span 80 in 100mL of toluene solution.

[0058] 3. Take 10 mL of the mixed solution obtained in step 1 as the dispersed phase and slowly add it to the continuous phase solution obtained in step 2, and stir homogeneously at a high speed to obtain an emulsion.

[0059] 4. Place the emulsion in a freezer at -20°C for 4 hours to freeze and quench.

[0060] 5. Pour the mixed coagulation solution of 1wt% NaOH ethanol water at -20°C into the quenched emulsion and soak for 3 hours.

[0061] 6. Centrifuge to obtain chitosan / gelatin composite microspheres, wash with ethanol and water for several times, and vacuum dry to obtain the product.

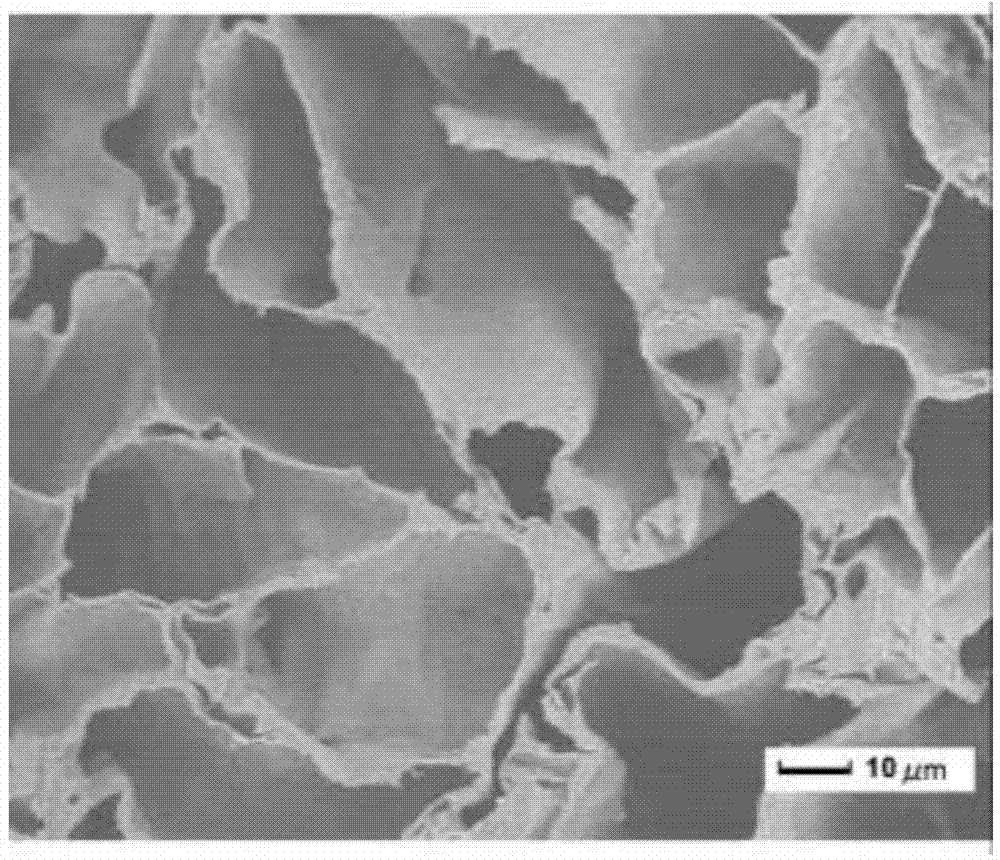

[0062] The chitosan / gelatin composite porous microsphere that present embodiment prepares, its morph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com