Skin filler used for injection and preparing method and application thereof

A technology for dermal fillers and injections, applied in the field of dermal fillers for injections and its preparation, can solve the problems of stimulating autoimmune disorders, increasing occurrence position shift, impaired skin metabolism, etc., achieving good biocompatibility, The effect of increasing the load factor and reducing the risk of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

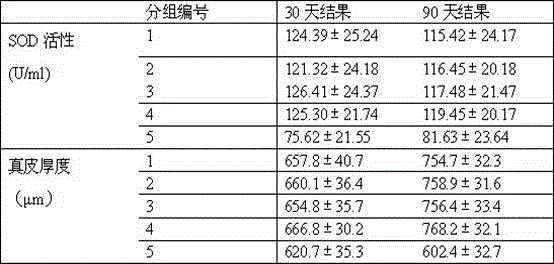

Examples

preparation example Construction

[0029] The present invention also includes a preparation method of a dermal filler for injection, comprising the following steps:

[0030] ①Add ethylene glycol monomethyl ether into a vacuum reaction flask, add stannous octoate, lactic acid and glycolic acid after vacuum dehydration to obtain a mixed solution, and react the mixed solution under vacuum conditions at 145~155°C for 8~12 hours to obtain Reaction solution; the mass ratio of the ethylene glycol monomethyl ether, stannous octoate, lactic acid and glycolic acid is 3~8:0.02~0.2:70~90:5~20;

[0031] ②Add dichloromethane to dissolve the reaction solution obtained in step ①, then add ethanol and stir to obtain a precipitate, and vacuum-dry the obtained precipitate at 45~55°C for 45~50 hours to obtain polyethylene glycol-polylactic acid-glycolic acid block copolymerization Material MPEG-PLGA; The mass volume ratio of described step 1. gained reaction solution, methylene chloride and ethanol is 1g: 3 ~ 5ml: 1 ~ 3ml;

[003...

Embodiment 1

[0048] A dermal filler for injection, consisting of the following raw materials: 7g of sodium carboxymethylcellulose, 9g of mannitol and 11g of hydrophilic modified polylactic acid microspheres loaded with antioxidant factors; the hydrophilic modified polylactic acid microspheres It is a porous microsphere composed of polyethylene glycol-polylactic acid-glycolic acid block copolymer MPEG-PLGA. The particle size of the hydrophilic modified polylactic acid microsphere is 30 microns, and the specific surface area is 1m 2 / g, the antioxidant factor is superoxide dismutase.

Embodiment 2

[0050] A dermal filler for injection, consisting of the following raw materials: 9 g of sodium carboxymethylcellulose, 11 g of mannitol and 13 g of hydrophilic modified polylactic acid microspheres loaded with antioxidant factors; the hydrophilic modified polylactic acid microspheres It is a porous microsphere composed of polyethylene glycol-polylactic acid-glycolic acid block copolymer MPEG-PLGA, the particle size of the hydrophilic modified polylactic acid microsphere is 150 microns, and the specific surface area is 12m 2 / g, the antioxidant factor is grape seed extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com