Foamed fluid additive for underbalance drilling

a technology of foaming fluid and additive, which is applied in the direction of borehole/well accessories, animal/human proteins, cytokeratin, etc., can solve the problems of agglomeration of drilling solids, and ineffective foaming of cationics, so as to reduce hydrostatic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

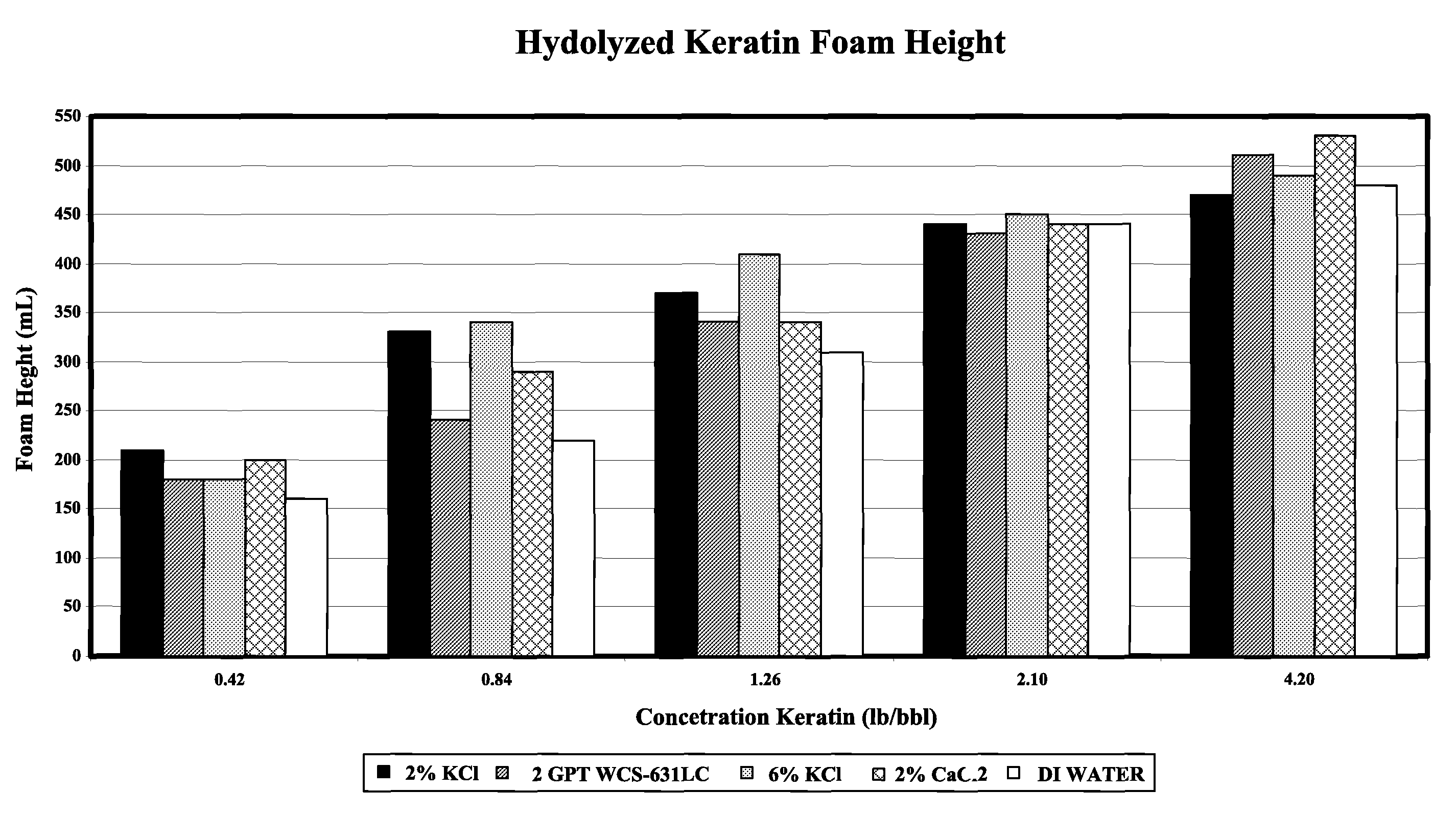

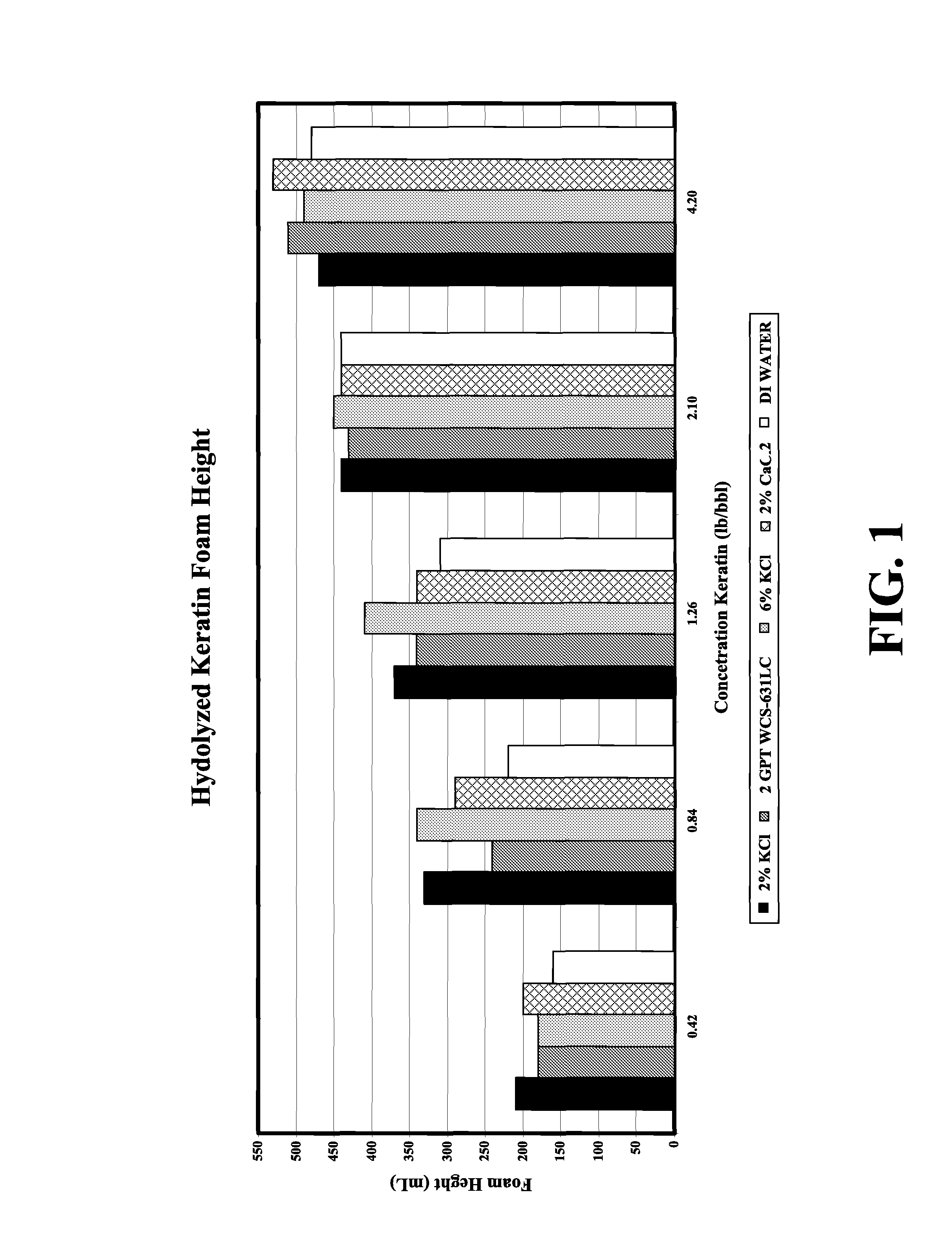

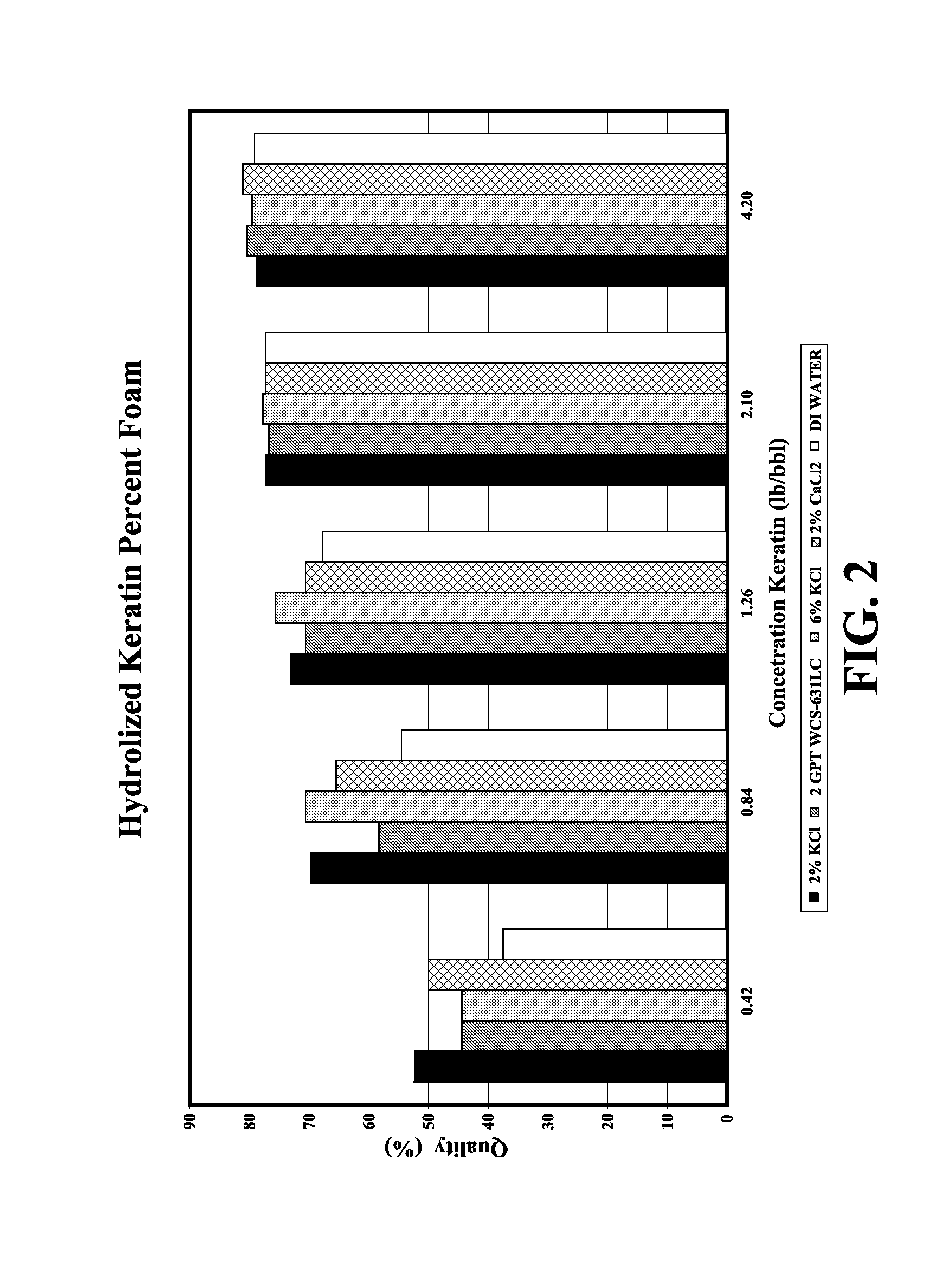

[0024]The inventors have found that a bio-degradable foaming composition for using in underbalanced or controlled pressure drilling can be formulated, where the foaming composition including an amino acid bio-material such as keratin. The foamer can be introduced into an underbalanced drilling system using conventional methods. The foamer can also be an additive in production chemicals, especially where the production chemicals are injected into a producing oil and / or gas well through a capillary tubing string downhole, where the foaming agent and gas are allowed to commingle downhole with production fluids to generate a foam that lightens the hydrostatic pressure of the column increasing an amount of production fluids produced by the well. The foamer can also be introduced into a producing well via a soap stick including a foaming composition of this invention. The difference in this invention is in the use of an unique environmentally friendly foamer for underbalance drilling appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com