Hydraulic jet perforation, fracturing and gas lift liquid drainage integrated technical pipe column

A technology of hydrojet and process string, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., which can solve the problems of multiple construction procedures, large reservoir damage, and long construction period, so as to save nitrogen resources, The effect of reducing damage and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

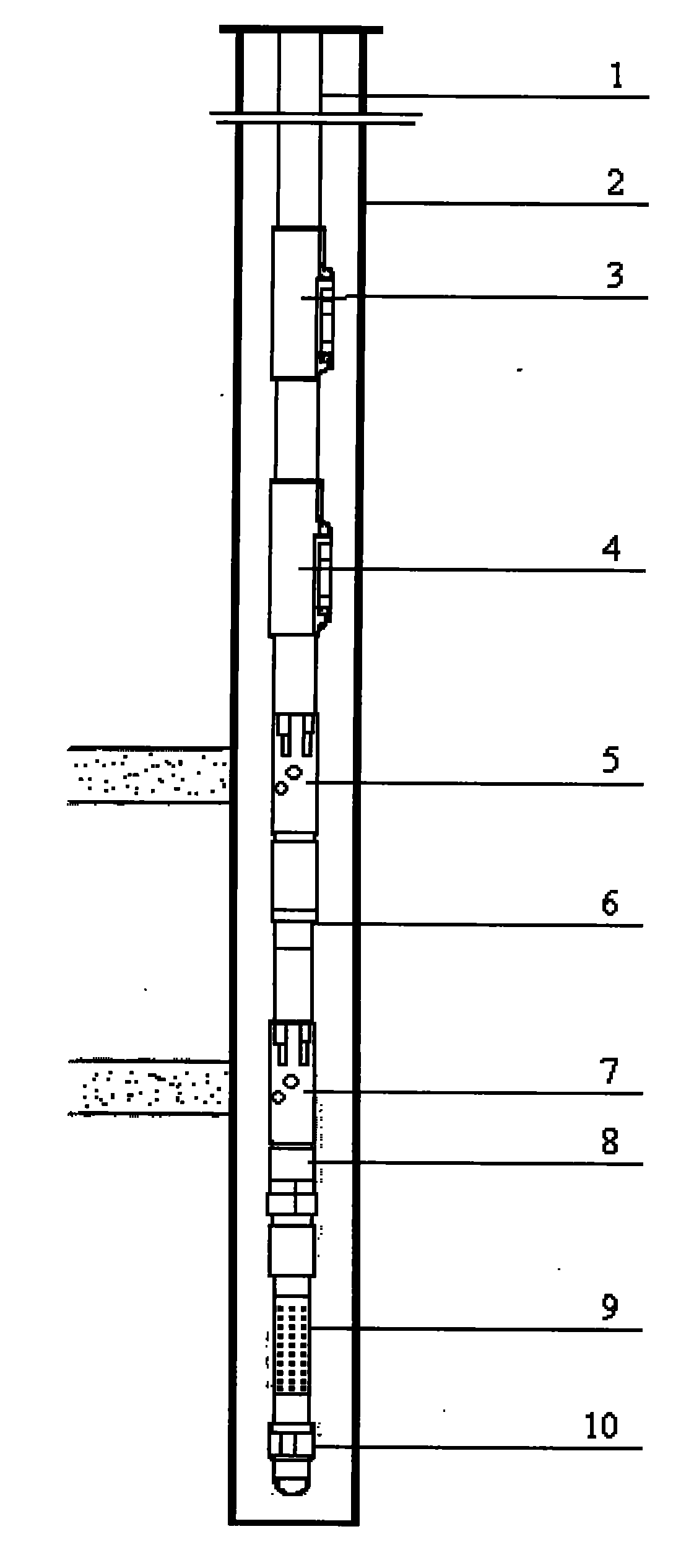

[0031] Embodiment 1: The present invention will be further described in detail by taking a hydraulic jet perforation fracturing gas-lift liquid drainage integrated process string that needs to be subjected to two-layer fracturing as an example.

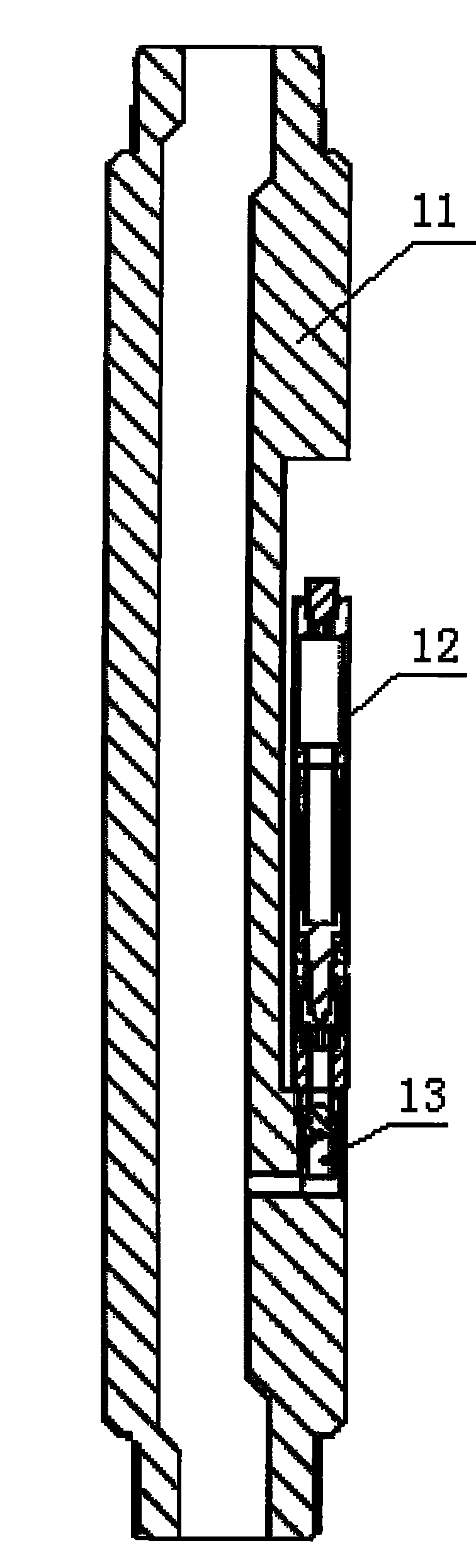

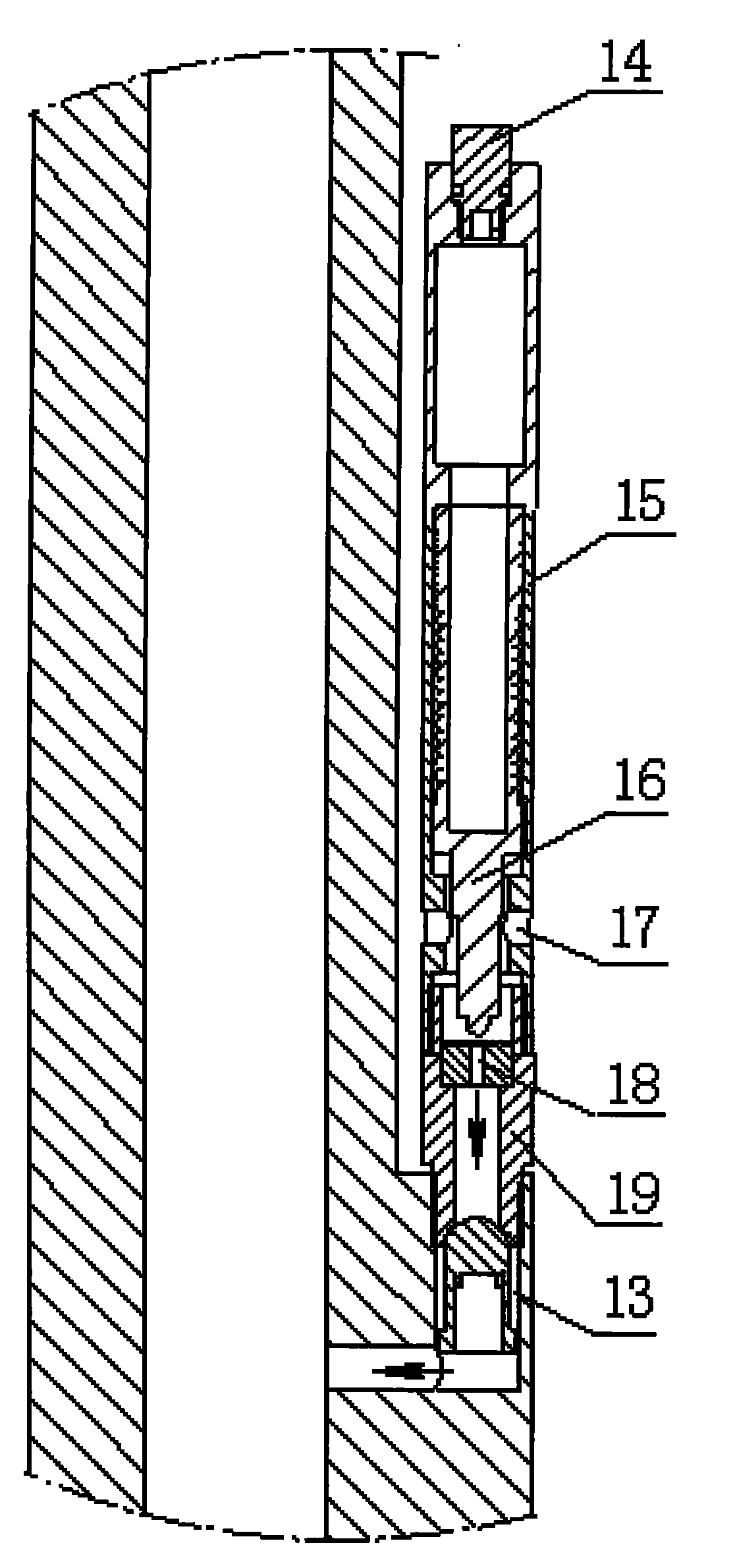

[0032] refer to figure 1. Hydraulic jet perforation fracturing gas lift drainage integrated process string, including tubing 1, primary gas lift valve 3, secondary gas lift valve 4, gas lift valve, primary hydraulic injector 5, sliding sleeve seat 6, It consists of a secondary hydraulic injector 7, a check valve 8, a screen pipe 9 and a plug 10. Inside the casing 2, there are two gas lift valves successively connected through the oil pipe 1 from top to bottom, that is, the primary gas lift valve 3 and the secondary gas lift valve 4. A first-stage hydraulic injector 5 is connected to the lower part of the second-stage gas lift valve 4 through the oil pipe, and a sliding sleeve seat 6 is connected to the lower part of the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com