Well drilling method of through tubing of gas lift under-balanced coiled tubing

An underbalanced drilling and coiled tubing technology, applied in drilling equipment and methods, directional drilling, drilling equipment, etc., can solve problems such as pressure rise in the well, gas moving up, endangering operation safety, etc., and improve the ability to carry cuttings , the effect of increased return speed and high maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

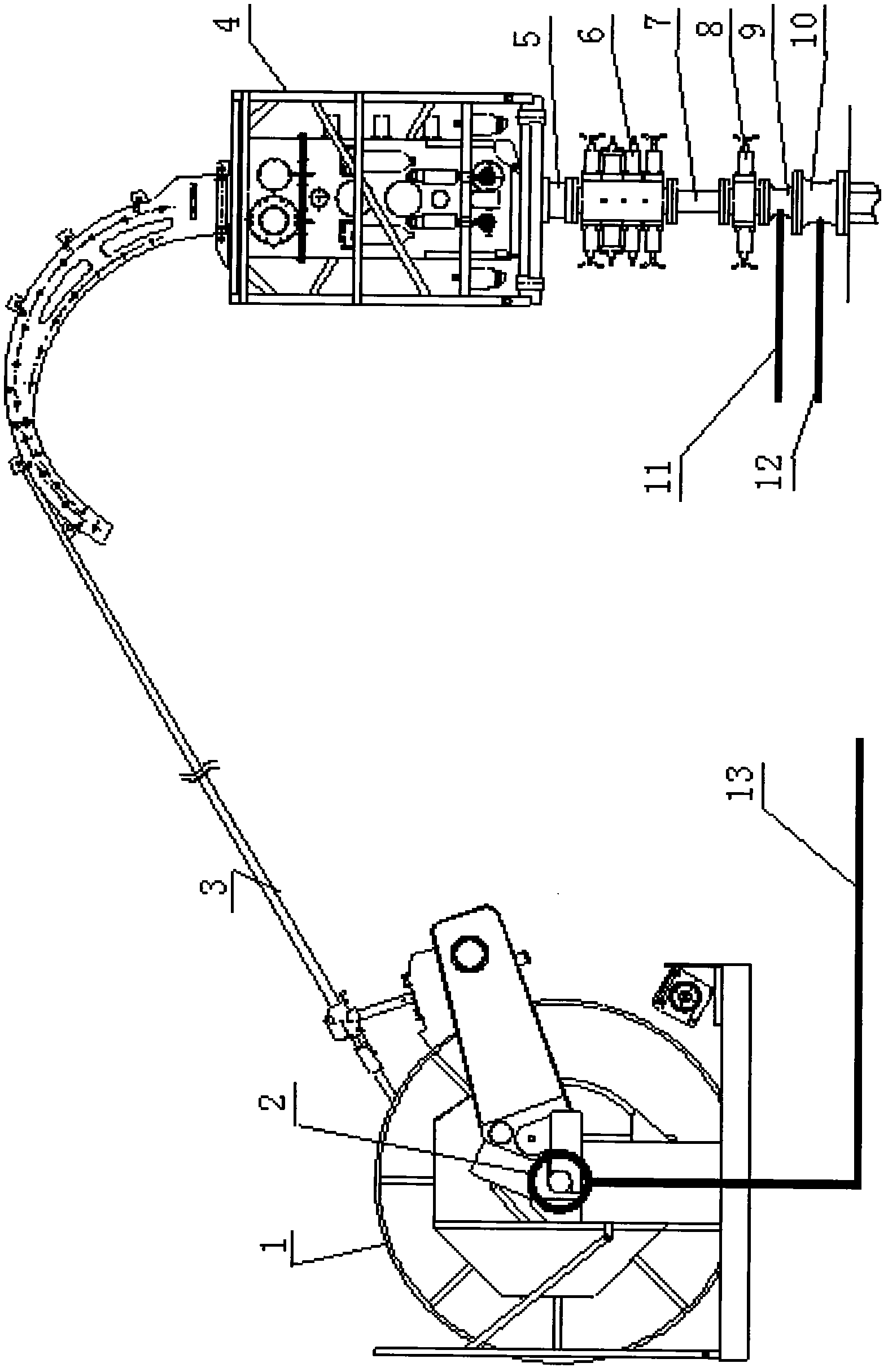

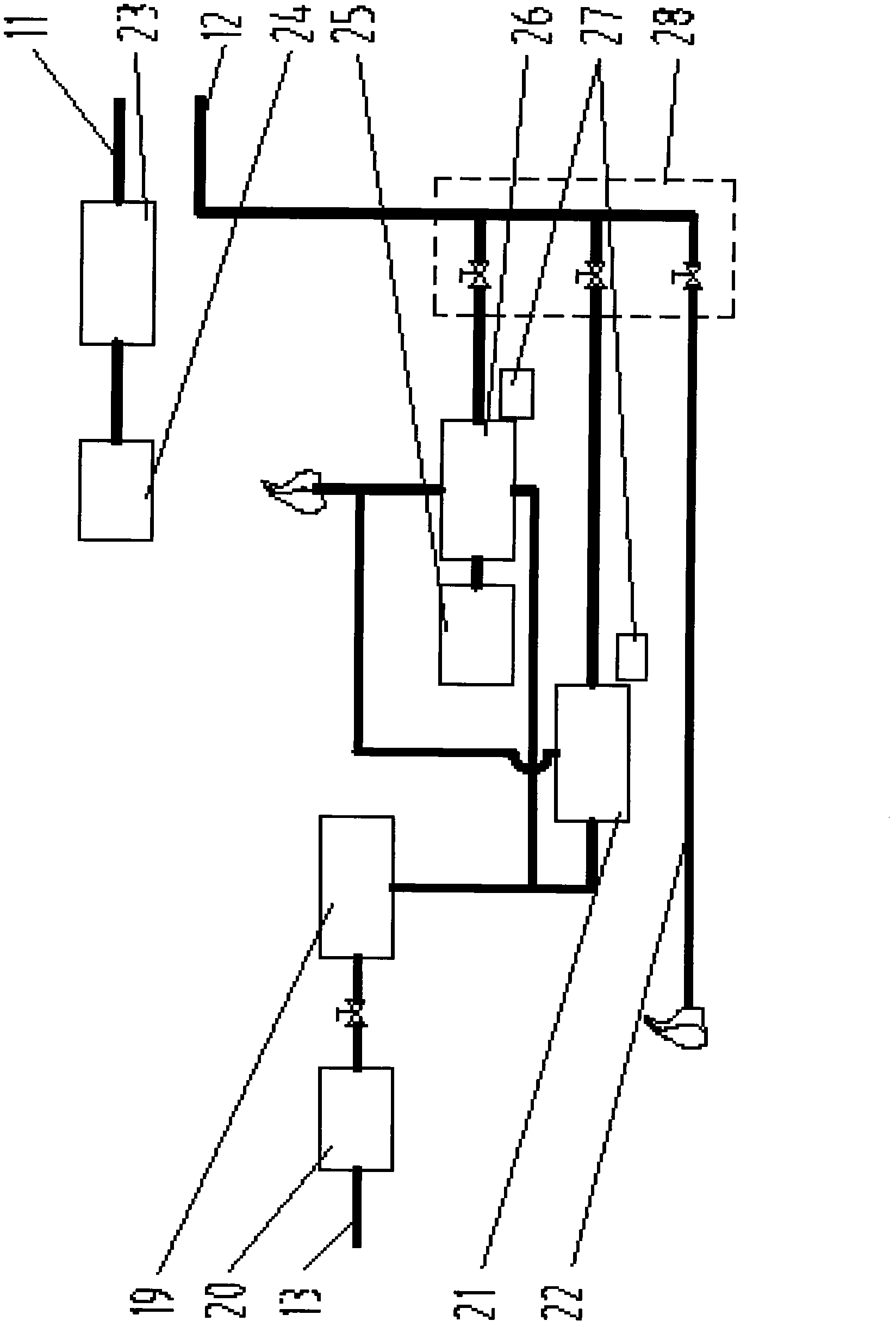

[0036] The gas-lift underbalanced coiled tubing through tubing drilling method proposed by the present invention is mainly used for performing underbalanced drilling or Low pressure drilling.

[0037] The specific embodiment of drilling technology of the present invention is described below in conjunction with accompanying drawing:

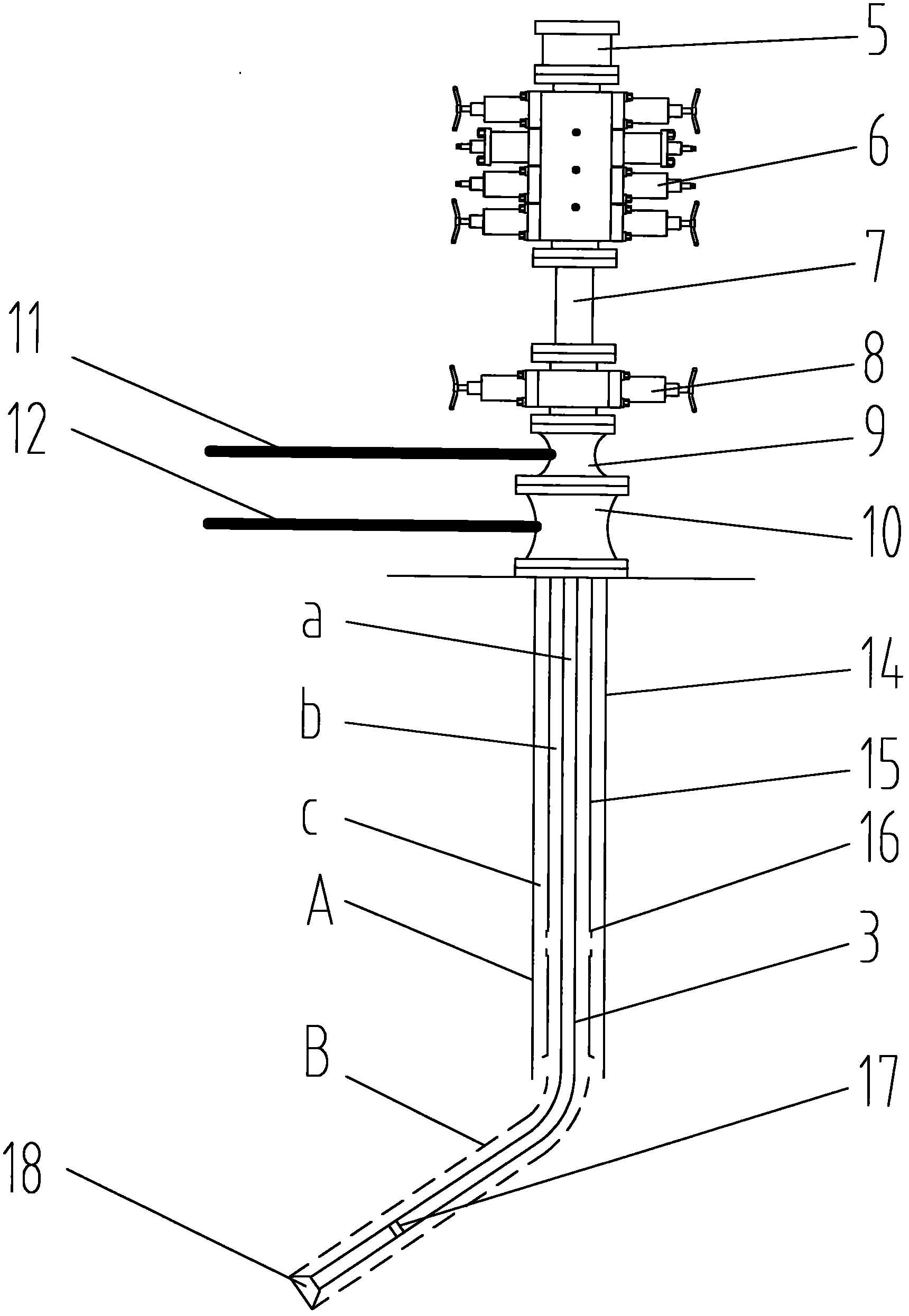

[0038] (1) see figure 2 . The operation is carried out after the upper wellbore A completes the cementing operation, and the target well section B in this embodiment is a directional well.

[0039] (2) According to the specifications of the inner casing 14 of the wellbore A and the requirements of the borehole diameter of the target well section B, select the specifications of the tubing 15 to be run in and the coiled tubing 3 to be used. The diameter of present embodiment sleeve pipe 14 is Select the diameter of oil pipe 15 as The diameter of the coiled tubing 3 is

[0040] (3) Install the casing head 10 and the oil pipe head 9, lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com