Subdivision ring type fast opening device for container sealing end cover and natural gas filter

A container sealing and dissecting technology, which is used in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of insufficient compact structure, unreasonable force, poor sealing, etc., and achieve a simple structure. , Unreasonable force, not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

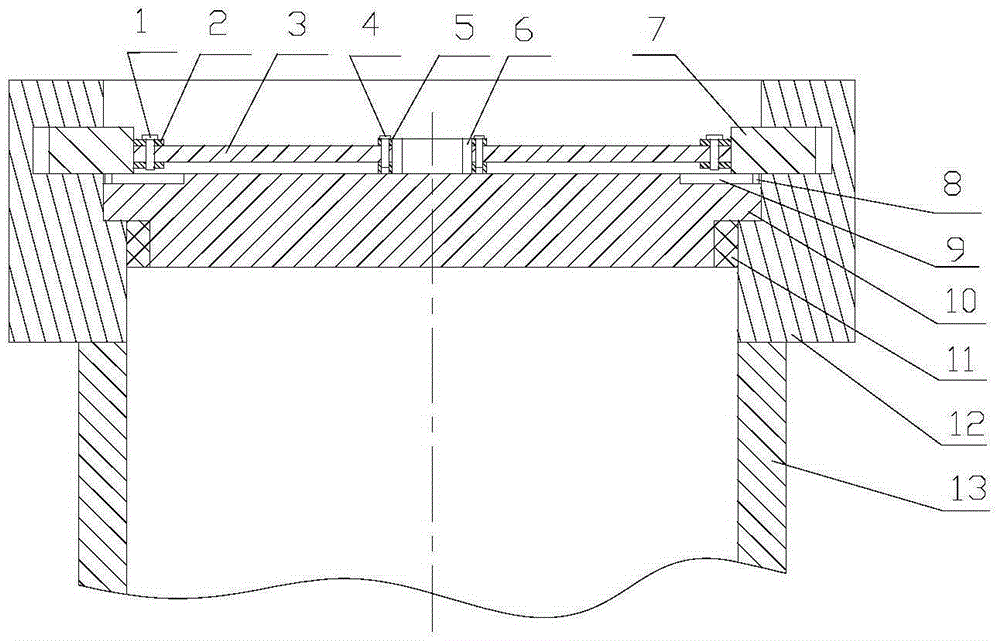

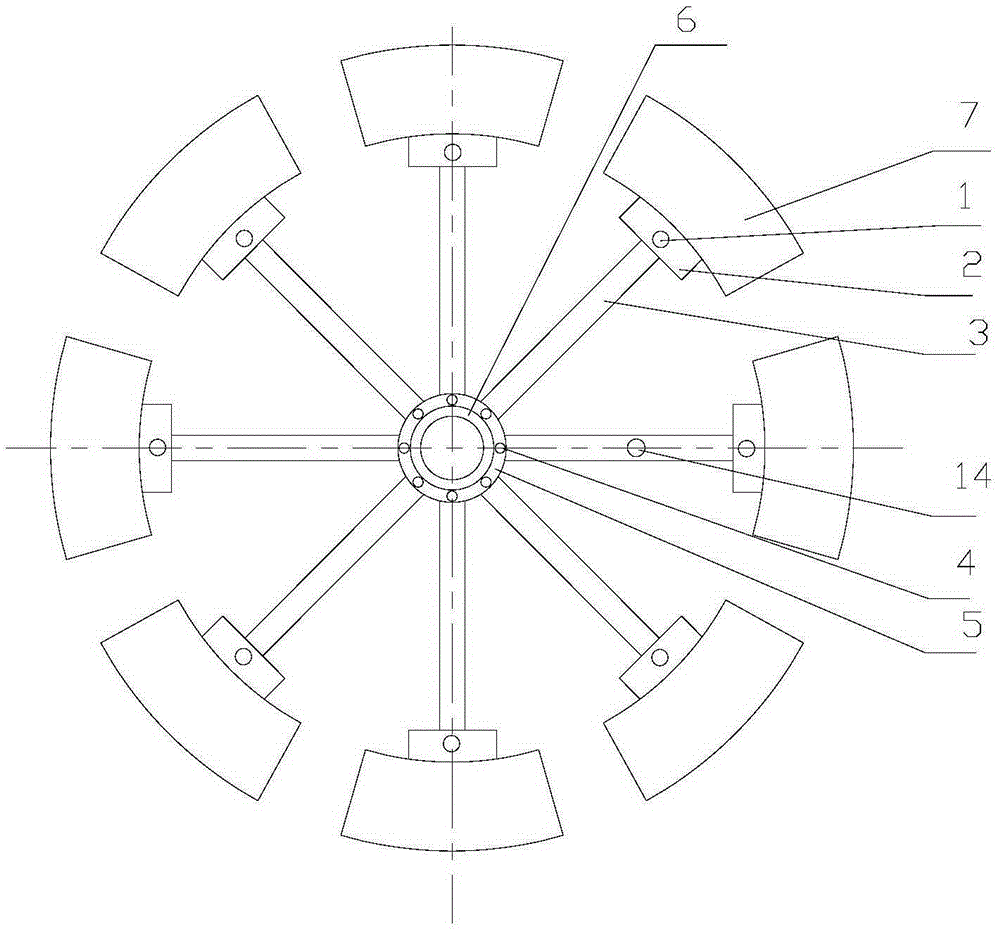

[0024] Such as figure 1 and figure 2 As shown, a split ring type quick-opening device for the sealing end cap of a container is set at the operating hole of the container, and its structure specifically includes a cylinder flange 12, a sealing ring 11, a flat cover 10, multiple sets of guide mechanisms and multiple sets of split rings. Claw mechanism;

[0025] The cylinder flange 12 is fixed at the operating hole of the container, and can be directly welded to one end of the cylinder, or a connecting piece can be installed on the container to weld the cylinder flange 12. The cylinder flange 12 includes an inner hole with a step; the flat cover 10 is arranged at the step of the inner hole, and a sealing ring 11 is provided between the flange 12 and the flat cover 10 . The sealing ring 11 can be arranged on the end surface.

[0026] Specifically in this example, the flat cover 10 is a variable diameter structure, and the shoulder of the variable diameter is in contact with t...

Embodiment 2

[0037] A natural gas filter, which adopts the above-mentioned container sealing end cap split ring type quick-opening device, and the opening on one side of the natural gas filter cylinder 13 is the operation hole.

[0038] Owing to adopting above-mentioned technical scheme, the present invention has following advantage and effect:

[0039] 1. It can effectively and safely realize the opening and closing action of the sealing end cap of the container, such as quick replacement of the filter core of the natural gas filter, with low labor intensity.

[0040] 2. The structure is compact and simple, and the space occupied is small.

[0041] 3. Changing the specific structural size can adapt to different work flow requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com