Oil based drilling cutting microemulsion cleaning solution and cleaning method thereof

A technology of oil-based drilling cuttings and cleaning fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex process, high cost, and inability to realize efficient recovery of base oil, and achieve simple process and low processing cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

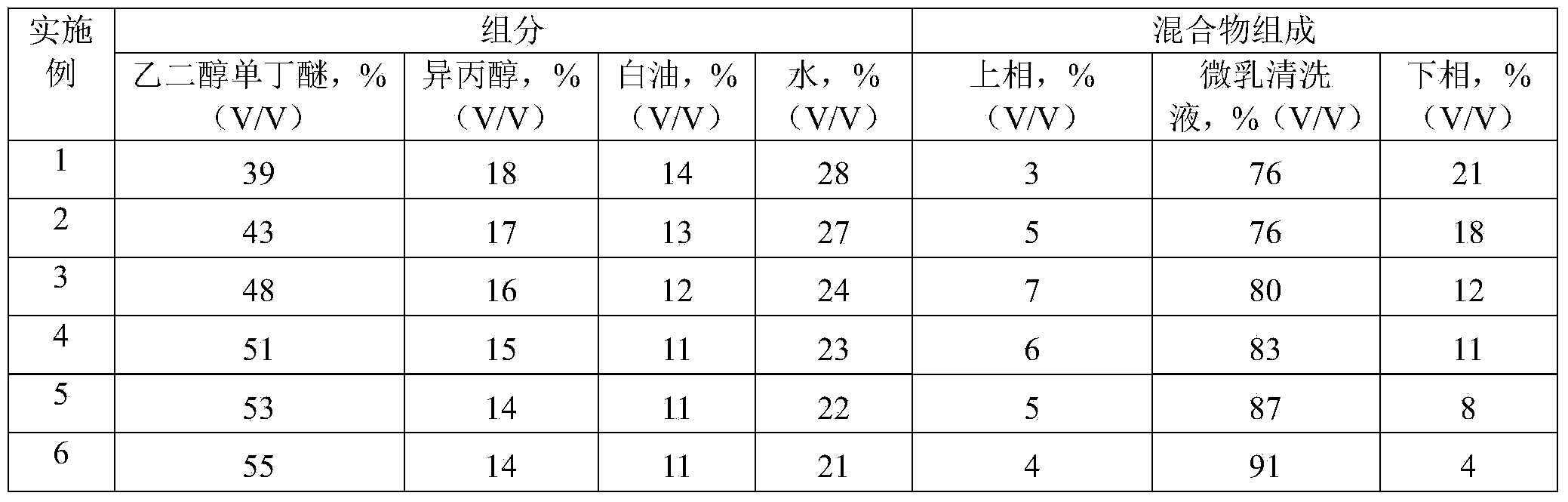

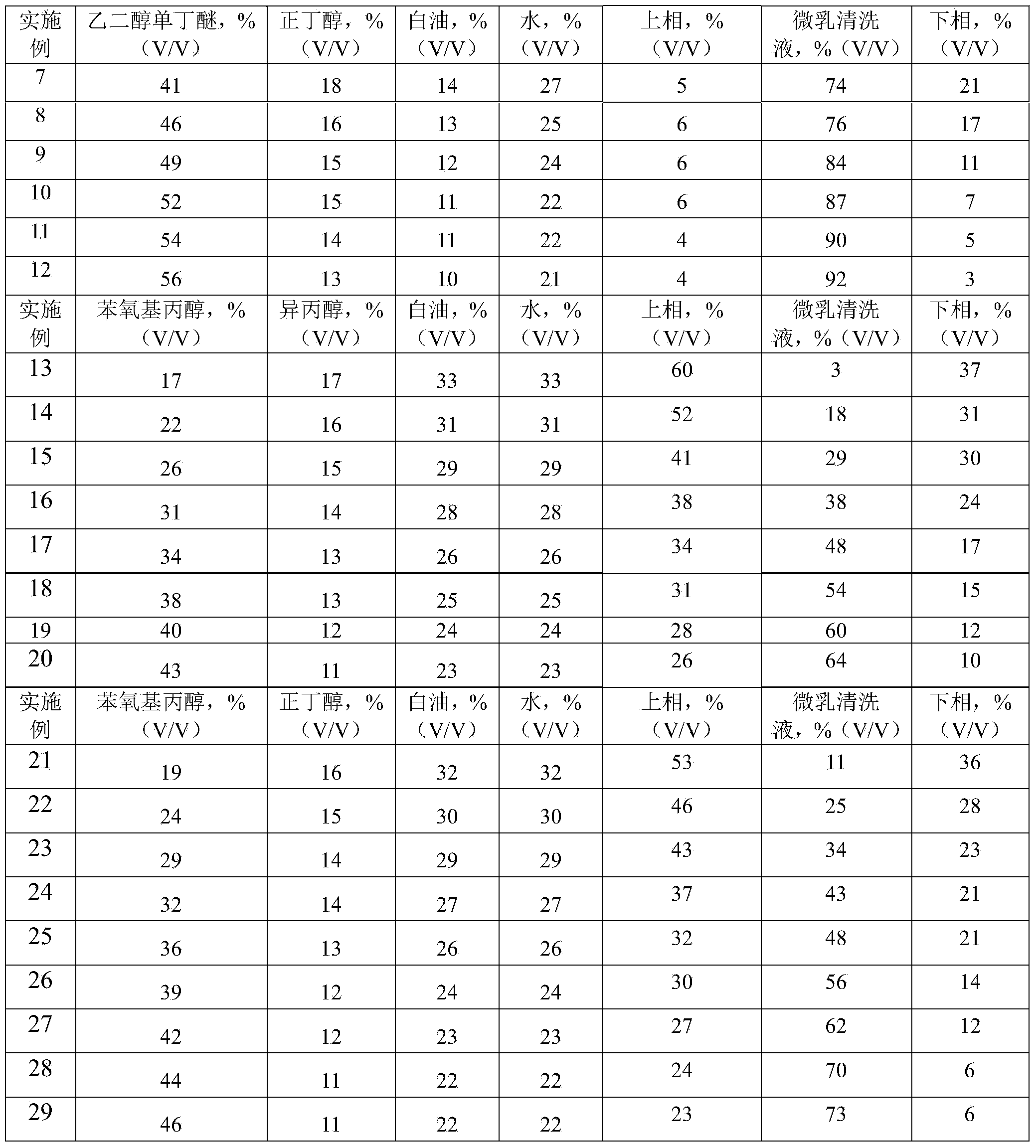

Examples

Embodiment 30

[0014] A sample of oil-based cuttings was taken from a well in Zhongyuan Oilfield, numbered 1, and the oil content of the cuttings was determined to be 21.27%. .

[0015] Mix 50 grams of the oil-based cuttings cleaning solution prepared in Example 5 with 25 grams of the cuttings sample evenly, control the stirring speed at 300 rpm, and stir for 30 minutes, and then enter the centrifuge for centrifugal separation at a centrifugal speed of 3500 rpm; the centrifugation time is 10 minutes, and the upper liquid phase Pour out, measure the volume, and determine the oil content in solid phase. Determination of specific data is as follows:

[0016] serial number

Embodiment 31

[0018] A sample of oil-based cuttings was taken from a well in Zhongyuan Oilfield, numbered as No. 2, and the oil content of the cuttings was determined to be 21.27%.

[0019] Mix 75 grams of the oil-based cuttings cleaning solution prepared in Example 11 with 25 grams of the cuttings sample evenly, control the stirring speed at 300 rpm, and stir for 30 minutes, then enter the centrifuge for centrifugal separation at a centrifugal speed of 3500 rpm; centrifuge for 10 minutes, and the upper liquid phase Pour out, measure the volume, and determine the oil content in solid phase. Determination of specific data is as follows:

[0020] serial number

Embodiment 32

[0022] The oil-based cuttings sample was taken from a gas field in Sichuan, numbered as No. 3, and the oil content of the cuttings was determined to be 9.86%.

[0023] Mix 50 grams of the oil-based cuttings cleaning solution prepared in Example 19 with 25 grams of the cuttings sample evenly, control the stirring speed at 350 rpm, and stir for 30 minutes, and then enter the centrifuge for centrifugal separation at a centrifugal speed of 4000 rpm; the centrifugation time is 10 minutes, and the upper liquid phase Pour out and determine the oil content in solid phase. The specific data are as follows:

[0024] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com