Gas Hydrate Harvesting

a gas hydrate and gas technology, applied in soil-shifting machines/dredgers, well accessories, wellbore/well accessories, etc., can solve the problems of limited progress towards harvesting this vast energy source, limited prior art satisfactorily addressing the significant challenge of efficiently removing the vast deposits of gas hydrates buried within seafloor sediments, and achieve efficient fluidization, rapid freeing of gas hydrate crystals, and cost-effective harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

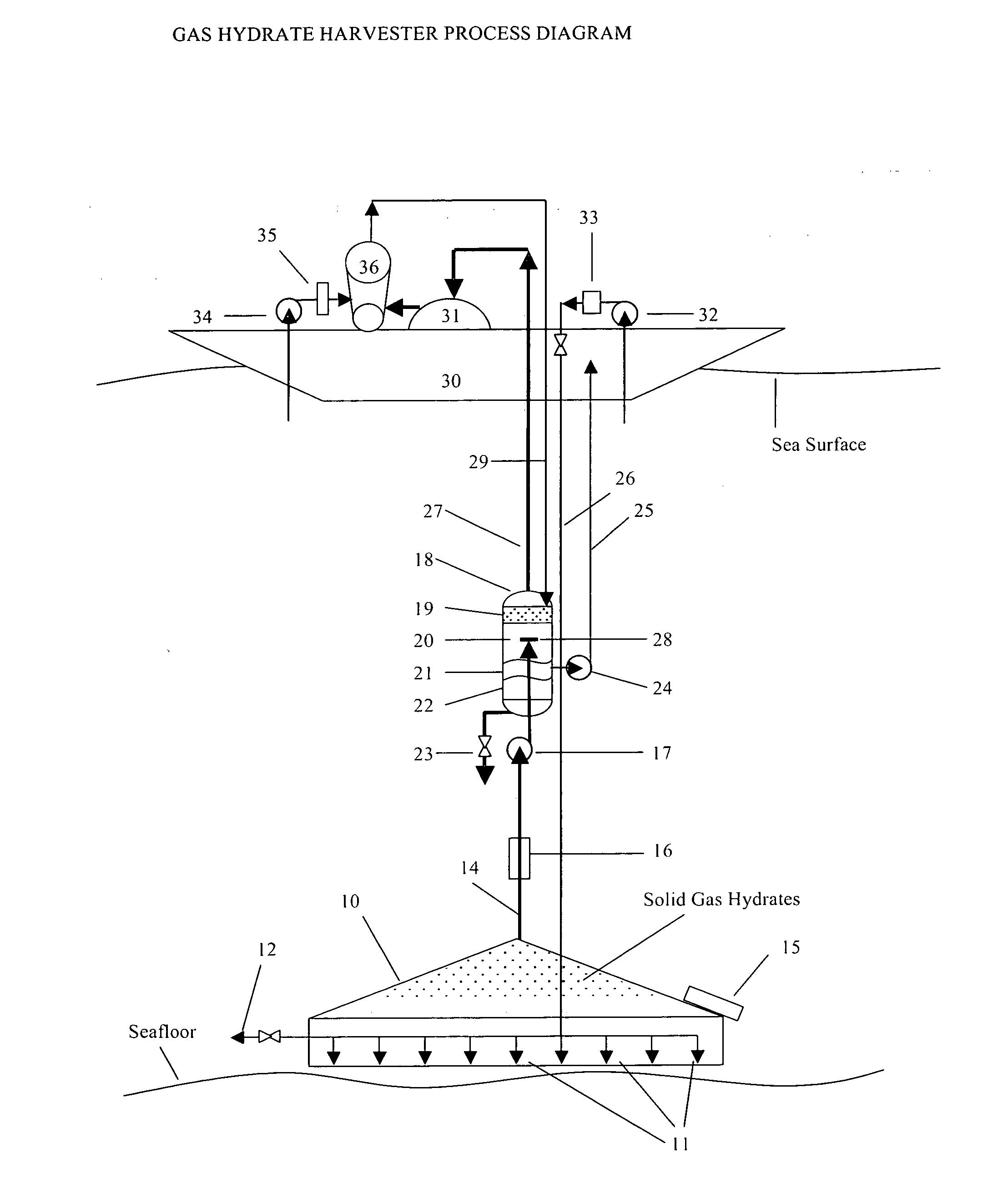

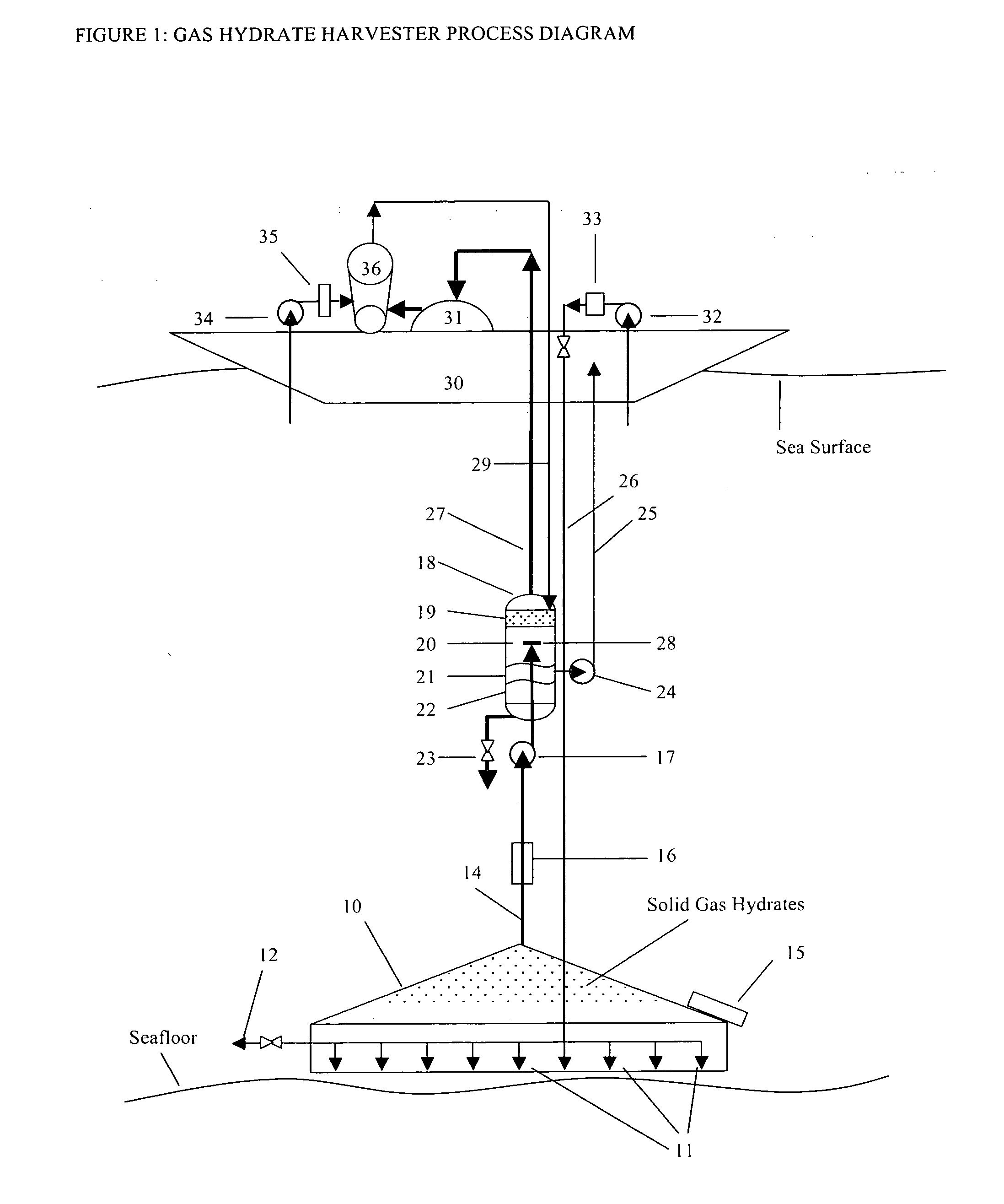

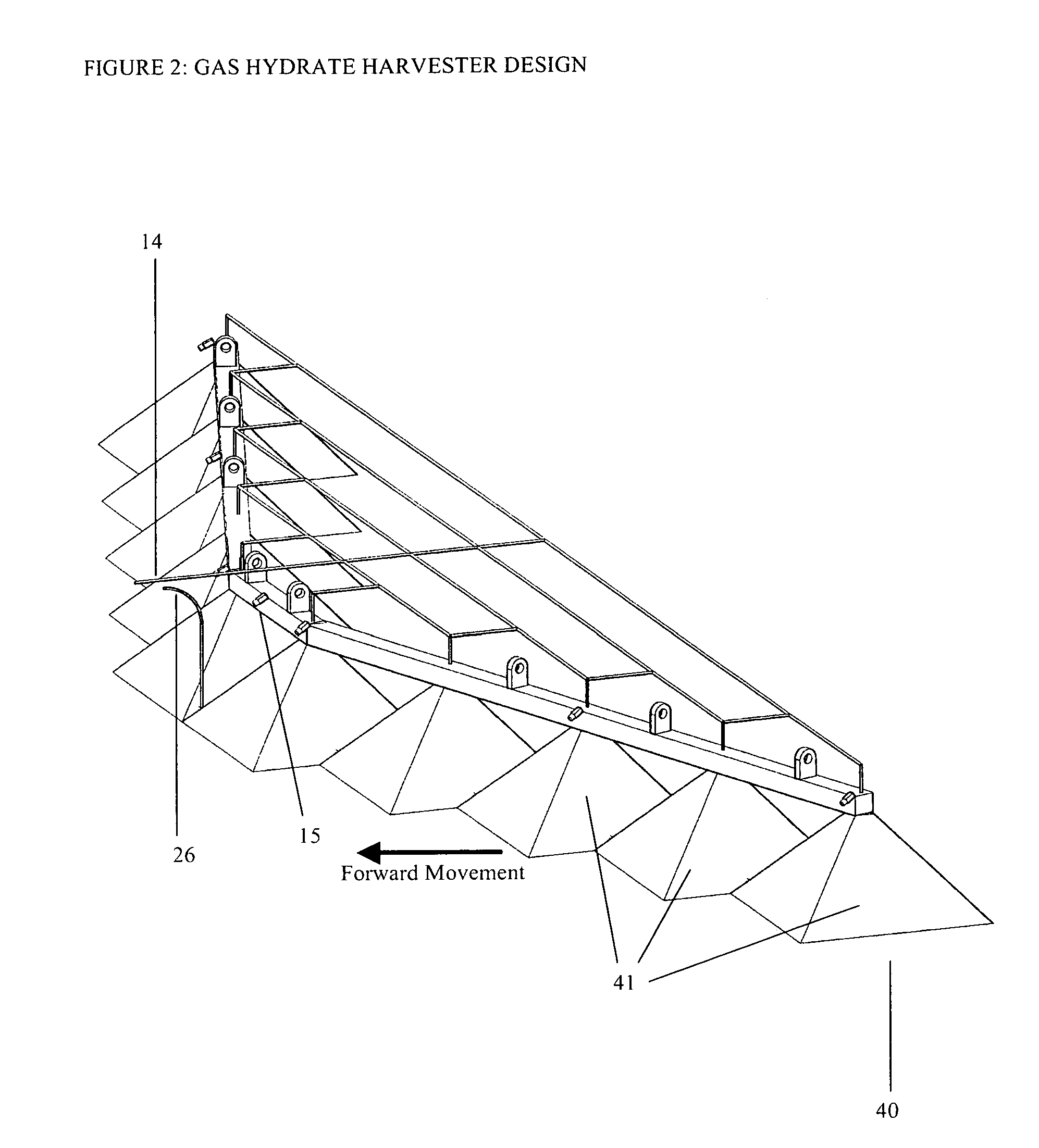

[0065]The invention as claimed is shown in FIG. 1 that utilizes a harvester 10 with a sloping, pyramid shaped roof that is open on the bottom. The harvester 10 fluidizes the seafloor sand and soil using high pressure warm water spray jets 11 that releases solid gas hydrate crystals from the pore spaces of the seafloor sand and soil. The warm water beneath the harvester 10 releases the gas hydrate crystals from any seafloor sand and soil. The lower density and resulting higher buoyant forces of the solid gas hydrate crystals causes them to float upward towards the harvester 10. The solid gas hydrate crystals that accumulate and concentrate beneath the harvester 10 then enter a hydrate slurry pipe 14 leading to a hydrate slurry pump 17 discharging flow into a separation vessel 18. When the warm spray water, seawater and solid gas hydrate crystals enter the separation vessel 18, the lower pressure and optional use of steam or hot water heating causes the dissociation of the gas hydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com