Low-smoke zero-halogen flame-retardant silane crosslinking polyolefin and preparation method thereof

A silane cross-linking and polyolefin technology, which is applied in the field of polymer materials, can solve the problems that the materials cannot be extruded smoothly, cannot be successfully realized, and the fluidity of the matrix resin is poor, so as to achieve the effect of improving the interfacial bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the above-mentioned low-smoke, halogen-free and flame-retardant silane crosslinked polyolefin, comprising the following steps:

[0027] (1) Preparation of silane-grafted polyolefin: melt-blending polyolefin resin, crosslinking initiator and unsaturated silane to obtain silane-grafted polyolefin;

[0028] (2) Preparation of catalyst masterbatch: polyolefin resin and catalyst are melt-blended to obtain catalyst masterbatch;

[0029] (3) Preparation of flame retardant masterbatch: melt blending thermoplastic elastomer and flame retardant to obtain flame retardant masterbatch;

[0030] (4) melt-blending the silane-grafted polyolefin prepared in steps (1)-(3), the catalyst masterbatch and the flame retardant masterbatch to obtain a low-smoke, halogen-free, flame-retardant silane crosslinked polyolefin;

[0031] Among them, the raw materials and their weight proportions are: 18-49 parts of polyolefin resin, 5-40 part...

Embodiment 1

[0035] Raw materials and their proportions:

[0036] 49 parts of linear low-density polyethylene, 23.2 parts of ethylene-butylene copolymer, flame retardant (a mixture of polyphosphate amine, melamine, pentaerythritol, and montmorillonite, wherein the weight ratio of polyphosphate amine, melamine, pentaerythritol, and montmorillonite 3:1:1:1) 25 parts, vinyltrimethoxysilane 1.35 parts, dicumyl peroxide 0.45 parts, dibutyltin dilaurate 1 part.

[0037] Preparation:

[0038] (1) Preparation of silane-grafted polyethylene: Mix linear low-density polyethylene (1.59 parts), dicumyl peroxide and vinyltrimethoxysilane, and blend and extrude in an extruder to obtain silane-grafted polyethylene For polyethylene blends, the temperature of each section of the extruder is 130°C, 160°C, 170°C, 180°C, and the speed is set at 55rpm;

[0039] (2) Preparation of catalyst masterbatch: mix linear low-density polyethylene (47.41 parts) with dibutyltin dilaurate according to the above ratio, and...

Embodiment 2

[0044] Raw materials and proportioning: 18 parts of low-density polyethylene, 8 parts of butadiene copolymer, 72 parts of aluminum hydroxide, 0.045 parts of vinyltriethoxysilane, 0.019 parts of benzoyl peroxide, and 0.05 parts of stannous octoate.

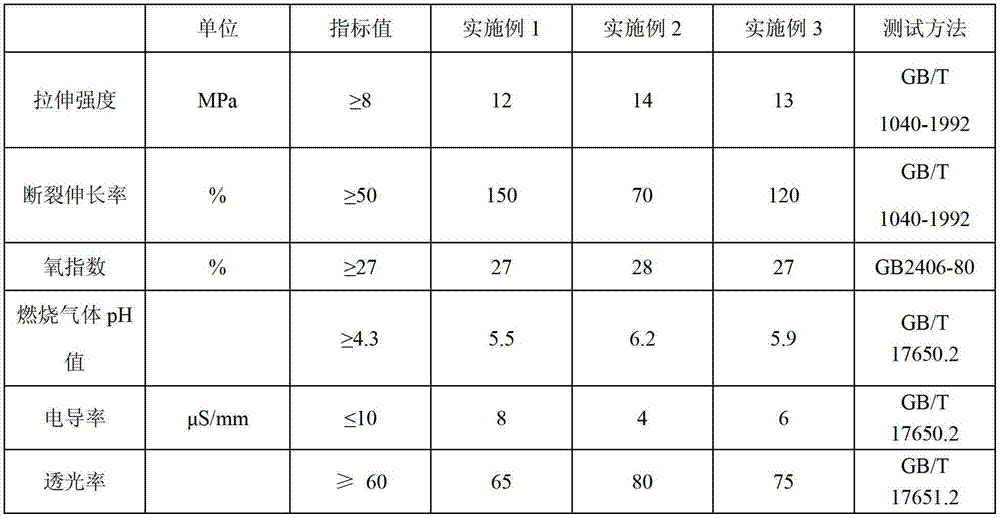

[0045] The specific preparation method is the same as in Example 1, and the total ratio of silane-grafted polyolefin to catalyst masterbatch is 9:1. The performance indicators of the obtained products are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com