Antisepsis and antidrag chemical additive of natural gas pipeline and preparation method thereof

A chemical additive, natural gas pipeline technology, applied in the direction of pipeline anti-corrosion/anti-rust protection, pipeline protection, anti-corrosion coating, etc., can solve the problems of increasing the potential accident rate, reducing the actual application effect, complicated operation, etc., to achieve good anti-corrosion function, reduce Collision friction energy loss, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

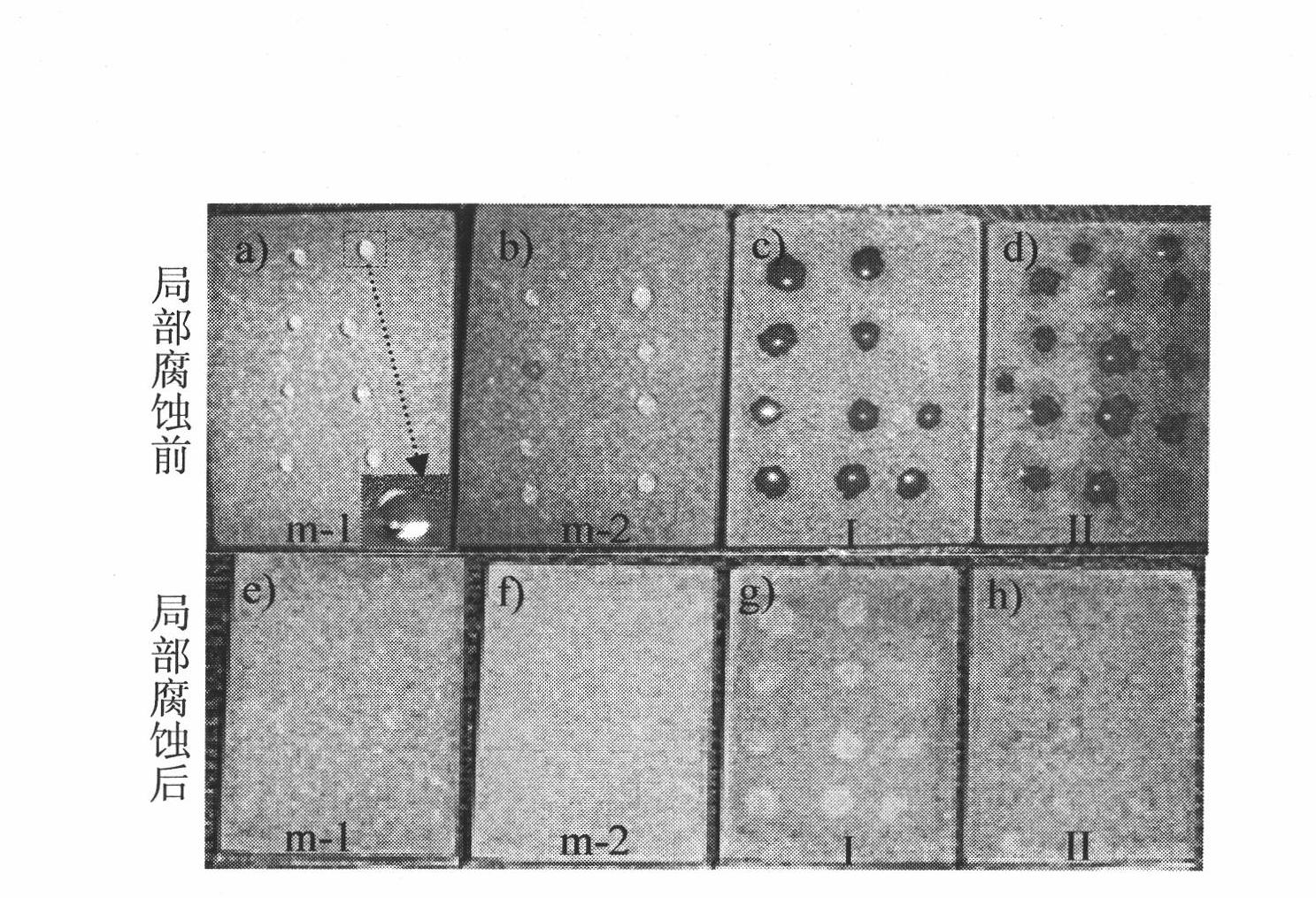

Image

Examples

Embodiment 1

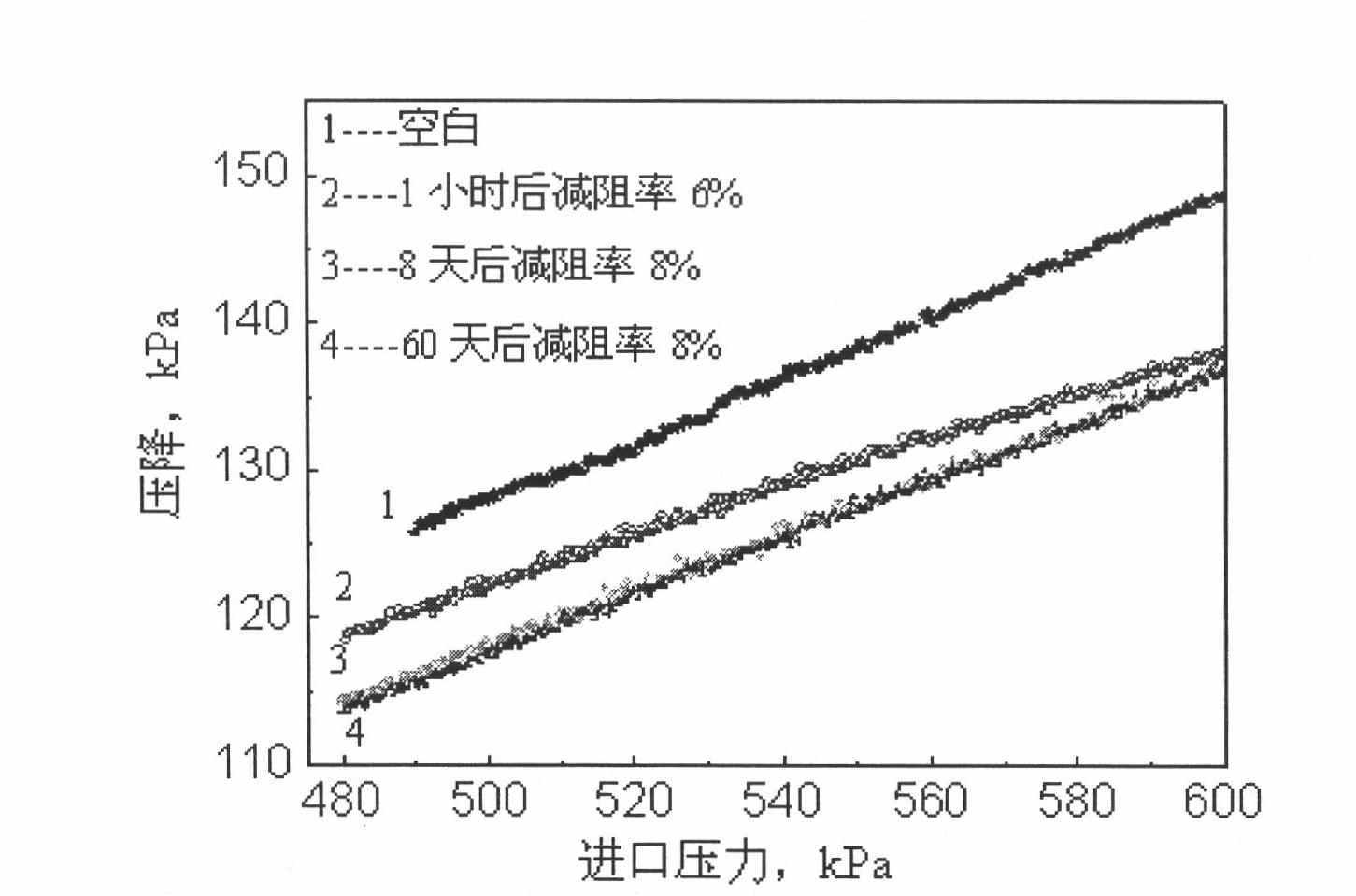

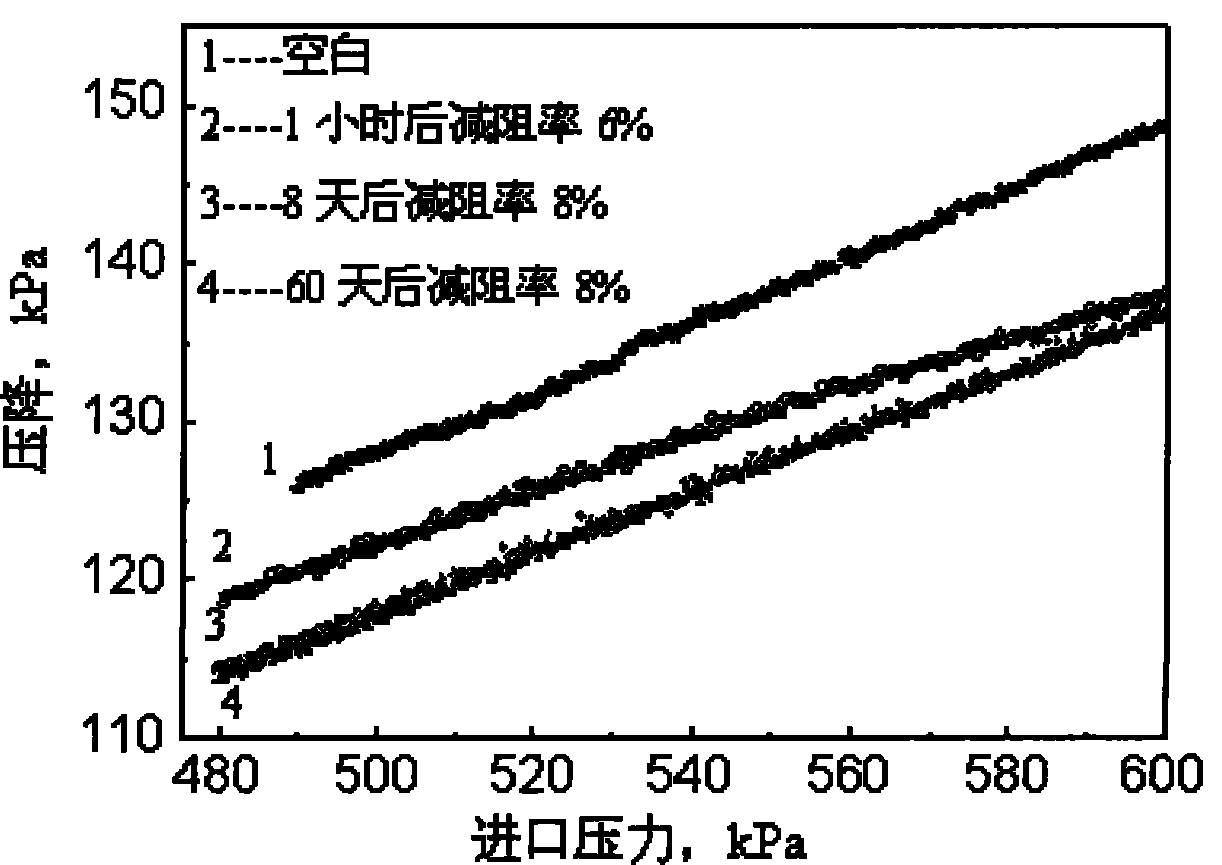

[0014] Embodiment 1. in the 500ml three-neck bottle that has thermometer and dropping funnel device, add platinum catalyst, add the mixture of trimethoxysilane (146 grams) and α-dodecene (168 grams) in dropping funnel, Wherein, the upper end of the dropping funnel is connected with the anhydrous calcium chloride drying tower with a grinding mouth elbow, the molar ratio of trimethoxysilane and α-dodecene is 1.2:1, and the molar ratio of platinum catalyst to α-dodecene is 11 ×10 -6 : 1. Open the dropping funnel, drop an appropriate amount of trimethoxysilane and α-dodecene mixture, heat in a water bath with magnetic stirring and start stirring, after the temperature of the mixture rises to 55°C, continue to drop the mixture at a constant temperature After dropping, close the valve of the dropping funnel to completely seal the three-necked bottle, slowly heat up to about 73°C, and the mixed solution is in a slightly boiling state. After reacting at a constant temperature for 2 ...

Embodiment 2

[0016] Embodiment 2. Take trimethoxysilane (146 grams) and α-dodecene (168 grams) as raw material, be 1: 1 and platinum catalyst (platinum catalyst and α-dodecene mol ratio are 10×10 -6- : 1) dodecyltrimethoxysilane is prepared under catalytic conditions, then methyltrimethoxysilane and synthetic dodecyltrimethoxysilane are successively added to the solvent in a molar ratio of 0.1:1 A 50wt.% solution is prepared by mixing n-hexane to form a chemical additive with anti-corrosion and drag-reducing functions.

[0017] The contact angle of the superhydrophobic molecular film formed by the chemical additive obtained in this embodiment on the inner wall of the steel block of the natural gas pipeline is 149°, and its static corrosion inhibition efficiency is 78%. Tested on a natural gas simulated pipeline, the average drag reduction rate is 8.5%, and the validity period is greater than 60 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com