A preparation method of phosphorus, nitrogen and boron multi-element synergistic wood flame retardant

A synergistic flame retardant, multi-element technology, applied in the field of wood flame retardants, can solve the problem of not fully meeting the needs of the market, and achieve the effect of improving the utilization rate of chemical atoms, strong penetration, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

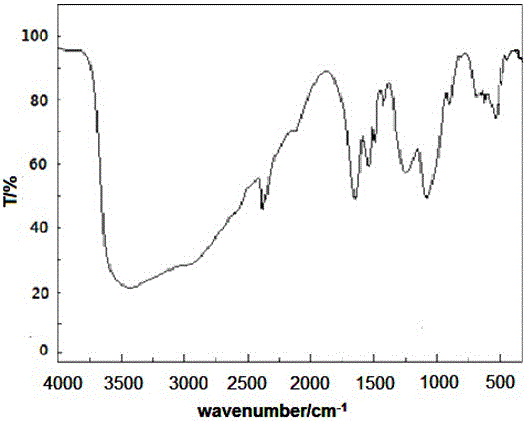

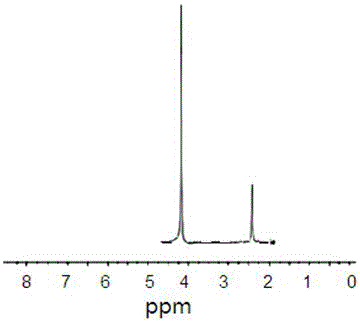

[0029] A method for preparing a phosphorus, nitrogen and boron multi-element synergistic wood flame retardant, comprising the following steps:

[0030] (1) Preparation of reaction equipment: install conventional stirrer, thermometer and fractionation device in a 250ml three-necked flask;

[0031] (2) Take 12.1g of trimethylolmethylamine, 14.01g of trimethyl phosphate and 60ml of dioxane in step (1) in a 250ml three-neck flask, heat to reflux, the reflux temperature is 102°C, and the reflux time is 12h. And control the temperature of the top of the column to not be higher than 65° C. through the fractionation device, continuously fractionate the methanol generated by the reaction until the fractionated methanol reaches the theoretical amount, and obtain the reaction solution a;

[0032] (3) Cool the reaction solution a obtained in step (2) to below 40°C, add dropwise 5.76g of phosphoric acid with a concentration of 85% by mass, stir for 1h, filter, and vacuum-dry the filter cak...

Embodiment 2

[0035] A method for preparing a phosphorus, nitrogen and boron multi-element synergistic wood flame retardant, comprising the following steps:

[0036] (1) Preparation of reaction equipment: install conventional stirrer, thermometer and fractionation device in a 250ml three-necked flask;

[0037] (2) Take 12.1g of trimethylolmethylamine, 18.21g of triethyl phosphate and 80ml of diethylene glycol dimethyl ether in step (1) 250ml three-neck flask, heat to reflux, the reflux temperature is 110°C, reflux The time is 11 hours, and the temperature of the column top is controlled by the fractionation device to be not higher than 78.5°C, and the ethanol generated by the reaction is continuously fractionated until the ethanol fractionated reaches the theoretical amount, and the reaction solution a is obtained;

[0038] (3) Cool the reaction solution a obtained in step (2) to below 40°C, add dropwise 5.76g of phosphoric acid with a concentration of 85% by mass, stir for 1h, filter, and ...

Embodiment 3

[0041] A method for preparing a phosphorus, nitrogen and boron multi-element synergistic wood flame retardant, comprising the following steps:

[0042] (1) Preparation of reaction equipment: install conventional stirrer, thermometer and fractionation device in a 250ml three-necked flask;

[0043] (2) Take 12.1g of trimethylolmethylamine, 22.42g of tri-n-propyl phosphate and 80ml of dimethyl sulfoxide, put them in a 250ml three-neck flask in step (1), heat to reflux, the reflux temperature is 130°C, and the reflux time is 9h , and the temperature of the column top is controlled by a fractionation device to be no higher than 97.7° C., and the n-propanol generated by the reaction is continuously fractionated until the fractionated n-propanol reaches the theoretical amount, and the reaction solution a is obtained;

[0044] (3) Cool the reaction solution a obtained in step (2) to below 40°C, add dropwise 5.76g of phosphoric acid with a concentration of 85% by mass, stir for 1h, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com