Injection device capable of adapting to low-temperature environment in foam drainage gas recovery

A foam drainage and injection device technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of no industrial power supply, low ambient temperature, and the inability to effectively use foam drainage gas recovery technology, etc., to achieve Ease of transportation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

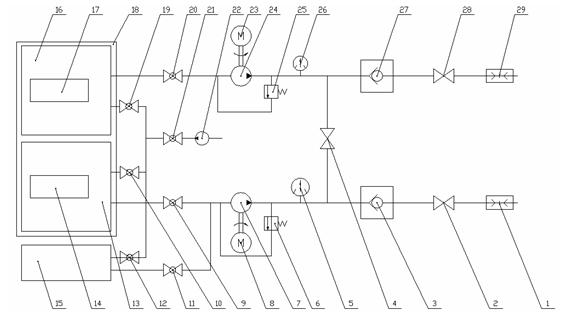

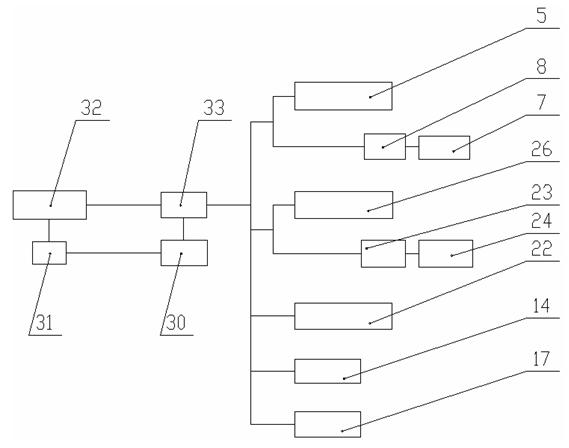

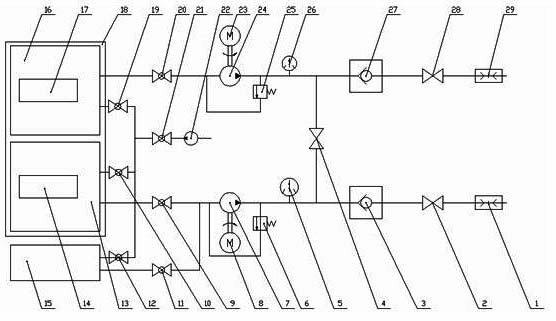

[0012] according to figure 1 , figure 2 As shown, the structural feature of the foam drainage and gas production injection device adapted to the low temperature environment is that the liquid filling pump 22 is connected to the ball valve 21 with a low-pressure pipeline, and then the ball valve 19, the ball valve 10, and the ball valve 12 are connected in parallel. The outlet end of 10 is connected to the chemical pool 13, the outlet end of the ball valve 12 is connected to the antifreeze tank 15, the electric heater 14 is set in the chemical pool 13, the electric heater 17 is set in the chemical pool 16, and exhaust jackets are installed around the chemical pool 13 and the chemical pool 16 18. The quick connector 1 is connected to the cut-off valve 2 with a pipeline, and then connected to the check valve 3. The other end of the check valve 3 is connected to the cut-off valve 4 with a three-way branch pipeline, and an electric contact pressure gauge 5 and a pressure gauge 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com