Energy-saving ultralow-temperature preservation box

An ultra-low temperature preservation and energy-saving technology, which is applied in lighting and heating equipment, refrigerators, compressors, etc., can solve the over-temperature protection and heat recovery requirements of compressors, and the throttling mode and unit operation energy saving have not been able to provide effective solutions. Program and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

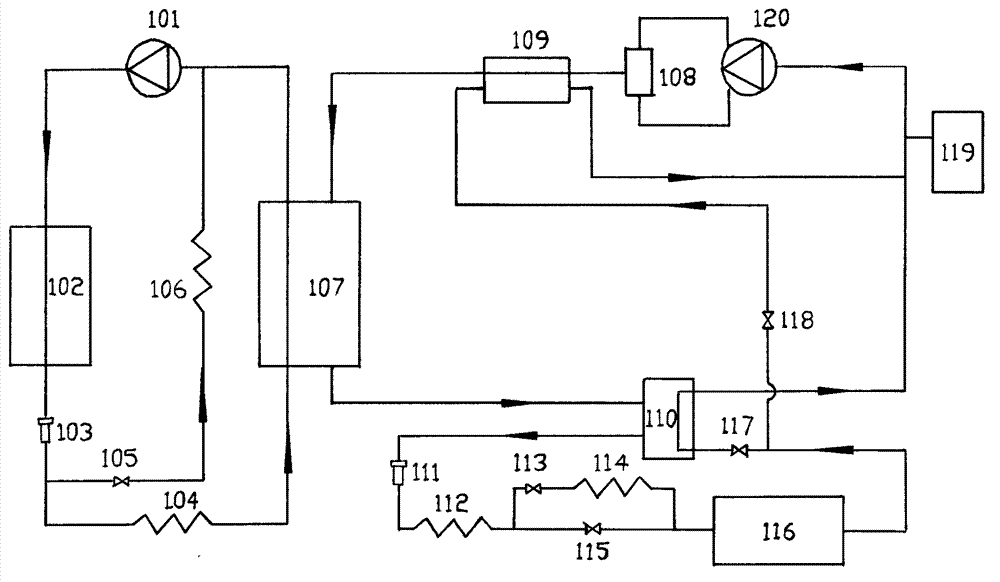

[0026] Example 1 After the high-temperature and low-temperature refrigeration cycle units are respectively evacuated, the high-temperature refrigeration cycle unit is injected with an appropriate amount of R290 refrigerant, and the low-temperature refrigeration cycle unit is injected with an appropriate amount of R23 refrigerant. The working temperature of the low-temperature preservation box is -60°C. First, the high-temperature compressor 101 is started, and the exhaust gas of the compressor 101 is condensed into a liquid through the condenser 102, and then throttled and cooled in the capillary tube 104 after passing through the dry filter 103, and the refrigerant from the capillary tube 104 is evaporated in the evaporative condenser 107, and then Go back to the compressor 101, so the cycle goes on and on, and the high-temperature refrigeration cycle is carried out.

[0027] When the temperature of the evaporative condenser drops to -32°C, the low-temperature compressor 120 s...

Embodiment 2

[0029] Example 2 After the high-temperature and low-temperature refrigeration cycle units are respectively evacuated, the high-temperature refrigeration cycle unit is injected with an appropriate amount of R404A refrigerant, and the low-temperature refrigeration cycle unit is injected with an appropriate amount of R508B refrigerant. The working temperature of the low-temperature preservation box is -86°C. First, the high-temperature compressor 101 is started, and the exhaust gas of the compressor 101 is condensed into a liquid through the condenser 102, and then throttled and cooled in the capillary tube 104 after passing through the dry filter 103, and the liquid from the capillary tube 104 evaporates in the evaporative condenser 107, and then returns to To the compressor 101, and so on, the high-temperature refrigeration cycle is carried out.

[0030] When the temperature of the evaporative condenser drops to -32°C, the low-temperature compressor 120 starts. The exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com