Method and device for measuring mixing velocity of gas-liquid two-phase flow of refrigerant

A gas-liquid two-phase flow, refrigeration technology, applied in fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problems of gas-liquid two-phase fluid that cannot measure phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

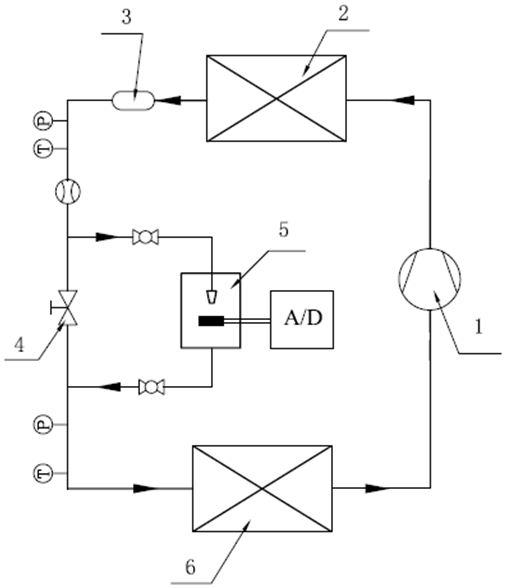

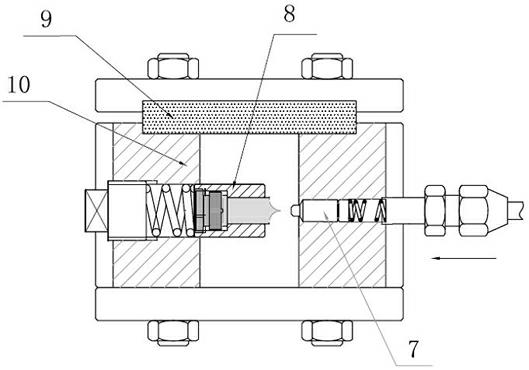

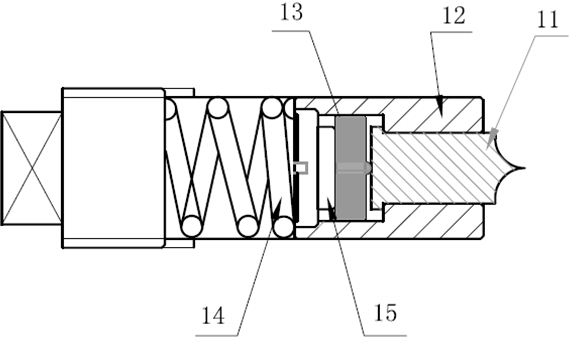

[0019] The method for measuring the mixing speed of the refrigerant gas-liquid two-phase flow of the present invention is to first measure the fluid mass flow rate m of the refrigerant in the refrigeration circuit and the ejection impact force F of the nozzle outlet, and then according to the formula F=-m(0-V 1 ) = mV 1 Calculate the average mixing velocity V of the refrigerant 1 . Wherein, the fluid mass flow m of the refrigerant is calculated by detecting the volume flow, pressure and temperature of the refrigerant at the inlet side of the nozzle. This calculation method is a prior art and will not be repeated here. Nozzle outlet jet impact force F is a electromechanical sensor component installed at the nozzle exit to detect the nozzle jet impact force. The electromechanical sensor component is affected by the nozzle impact force and converts the pressure signal into an electrical signal and then inputs it to the computer through the AD conversion circuit. obtained after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com