Multi-cylinder rotary compressor and refrigeration cycle device

A rotary compressor and multi-cylinder technology, which is applied to rotary piston machines, rotary piston pumps, rotary piston/oscillating piston pump components, etc., can solve problems such as reducing compression work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

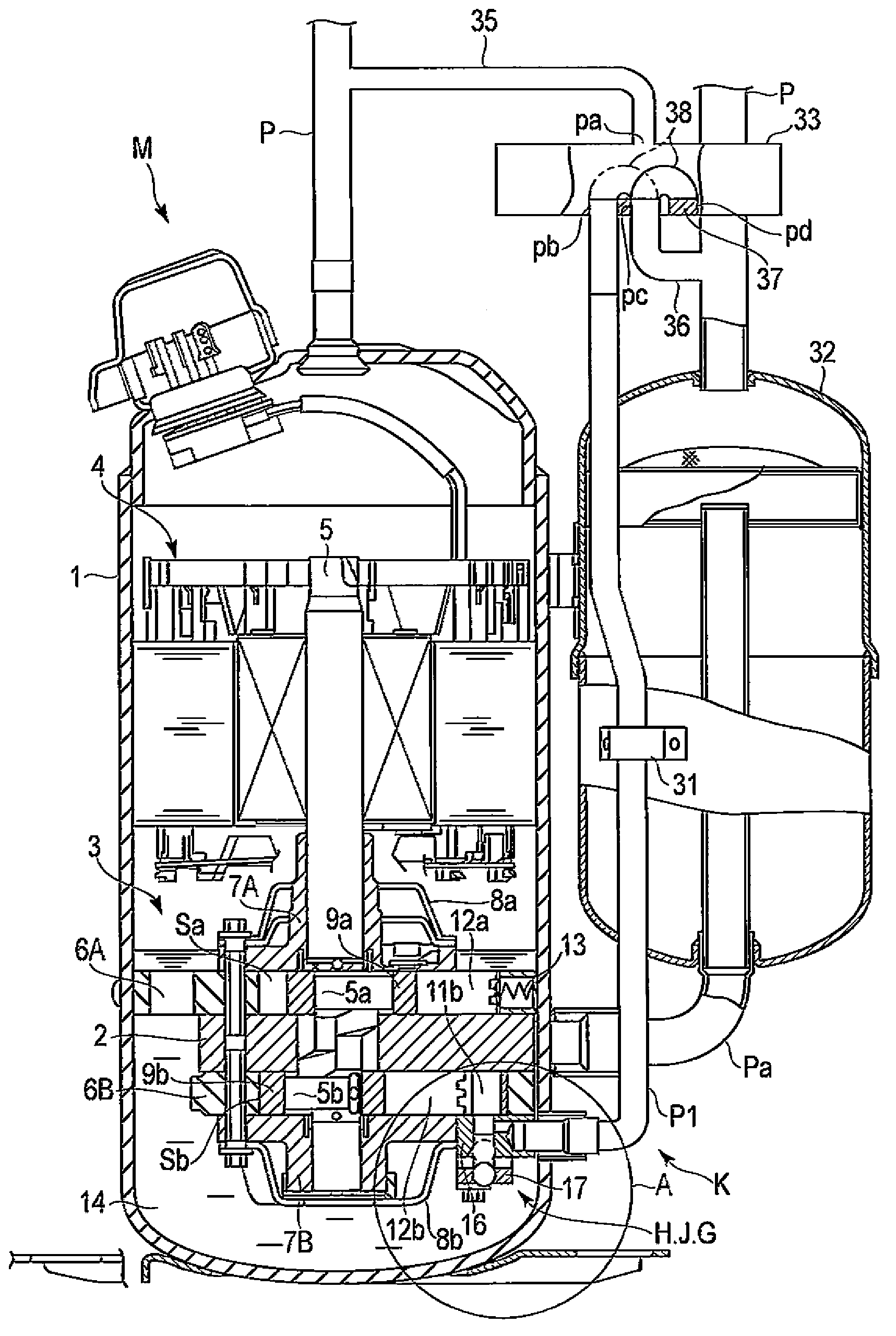

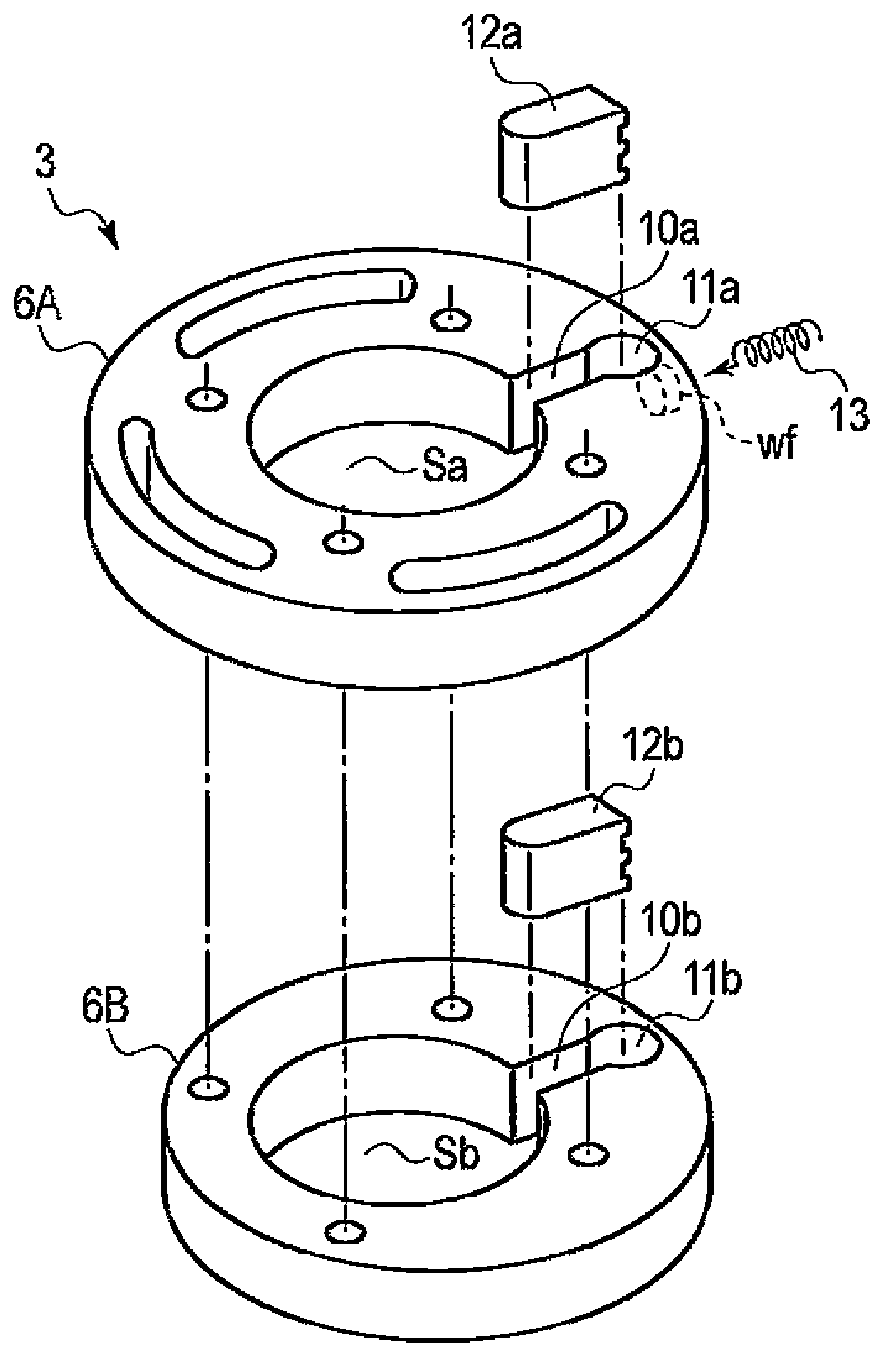

[0020] Hereinafter, this embodiment will be described based on the drawings. figure 1 It is a schematic longitudinal sectional view of the multi-cylinder rotary compressor M of this embodiment. Reference numeral 1 in the figure is an airtight case, and the compression mechanism part 3 is provided in the lower part in this airtight case 1, and the motor part 4 is provided in the upper part. The motor unit 4 and the compression mechanism unit 3 are integrally connected via a rotating shaft 5 .

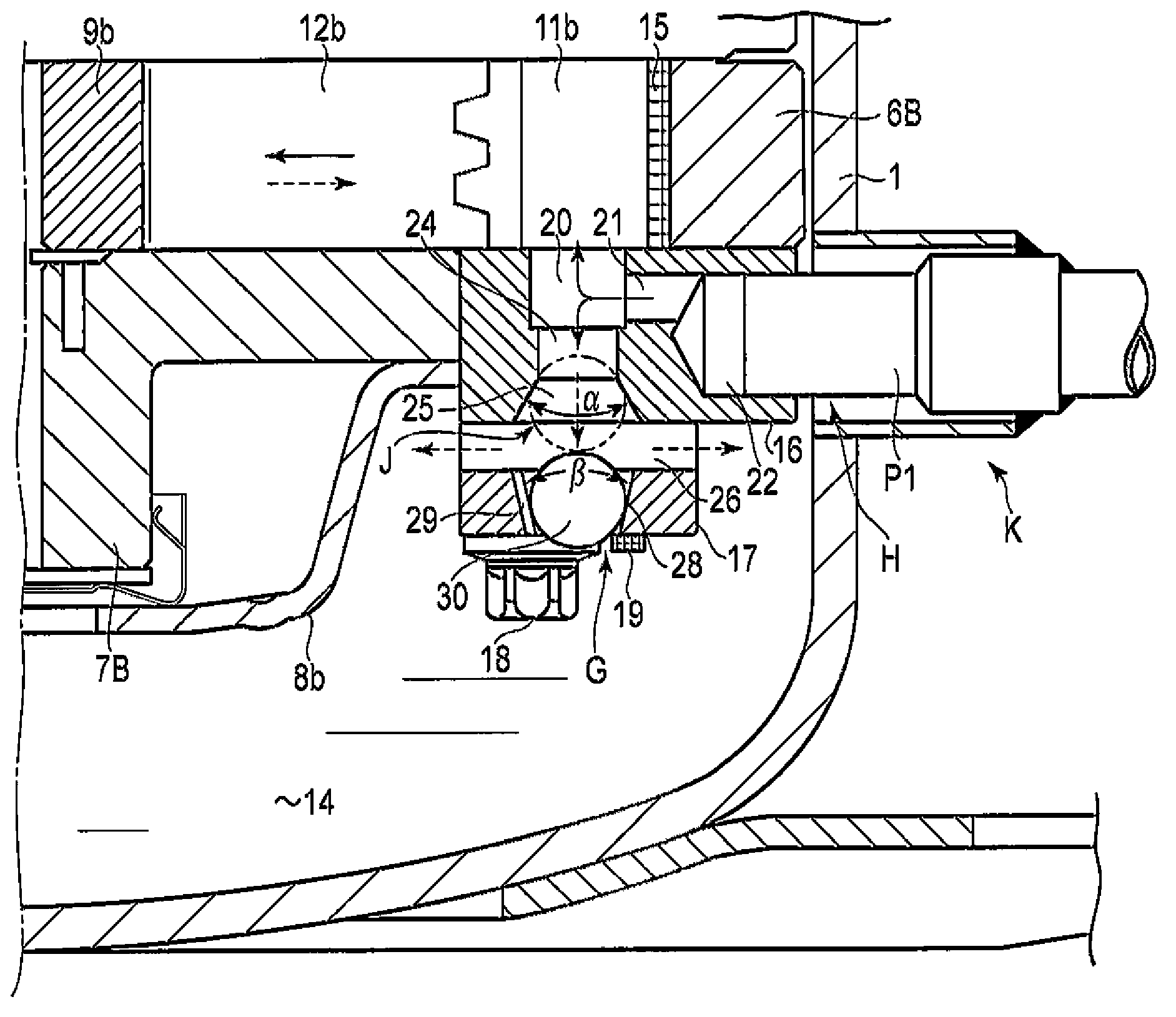

[0021] The compression mechanism unit 3 includes a first cylinder 6A on the upper side and a second cylinder 6B on the lower side. A main bearing 7A is fixed to the upper end surface of the first cylinder 6A, and a sub-bearing 7B is fixed to the lower end surface of the second cylinder 6B. The intermediate partition plate 2 is interposed between the first cylinder 6A and the second cylinder 6B.

[0022] The above-mentioned rotary shaft 5 penetrates the inside of each cylinder 6A, 6B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com