Sealed compressor

A compressor, airtight technology, applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem of severe sliding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

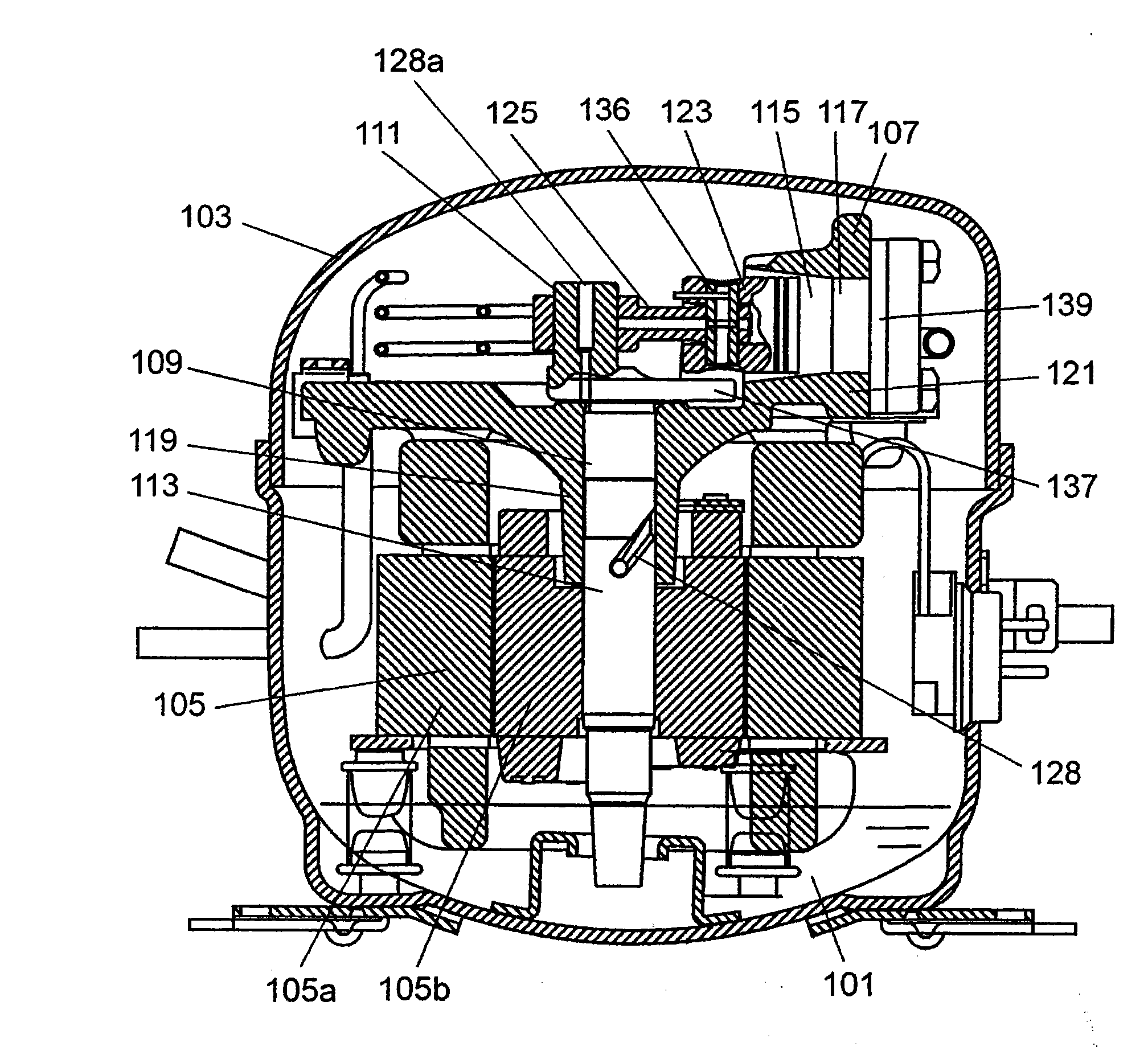

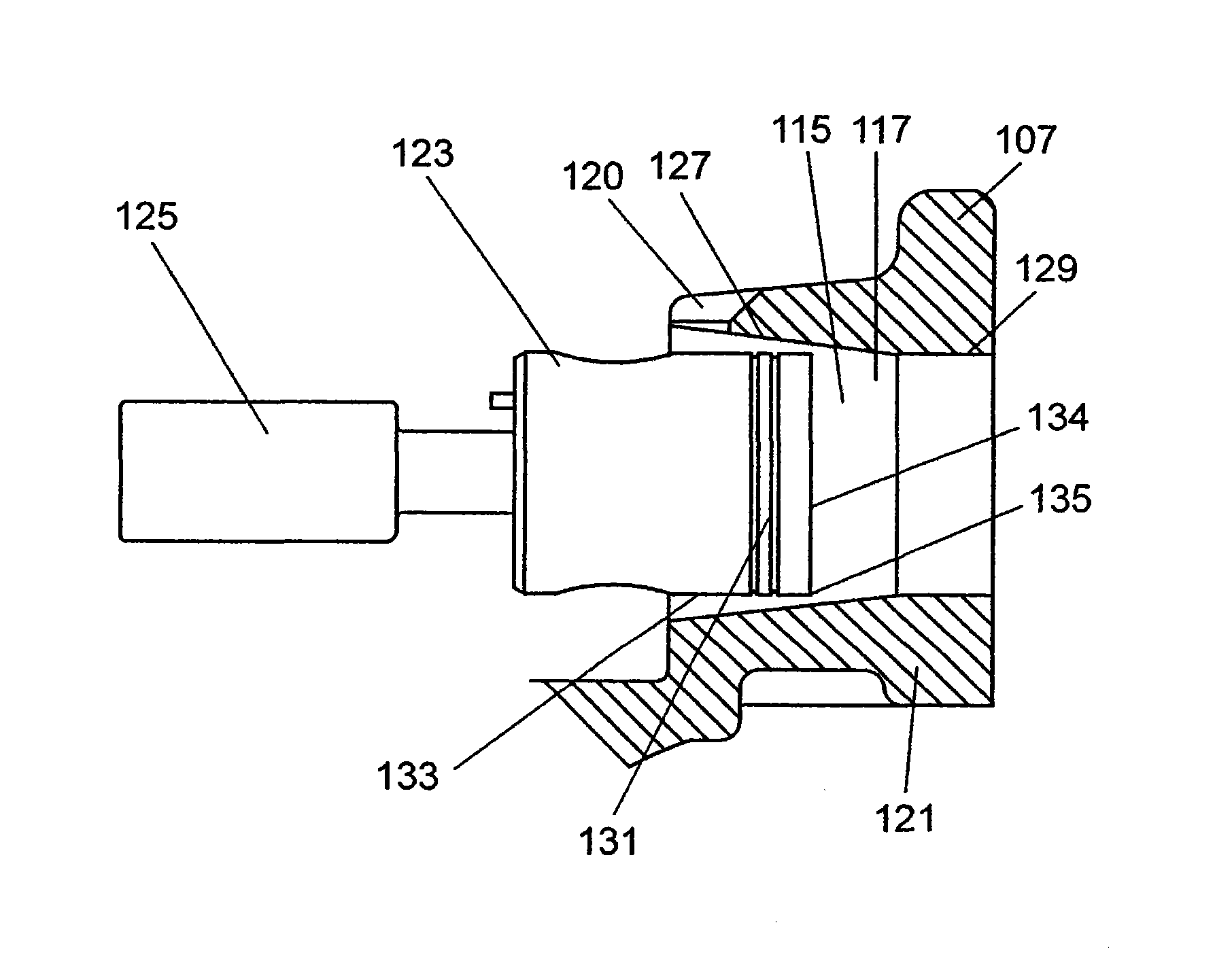

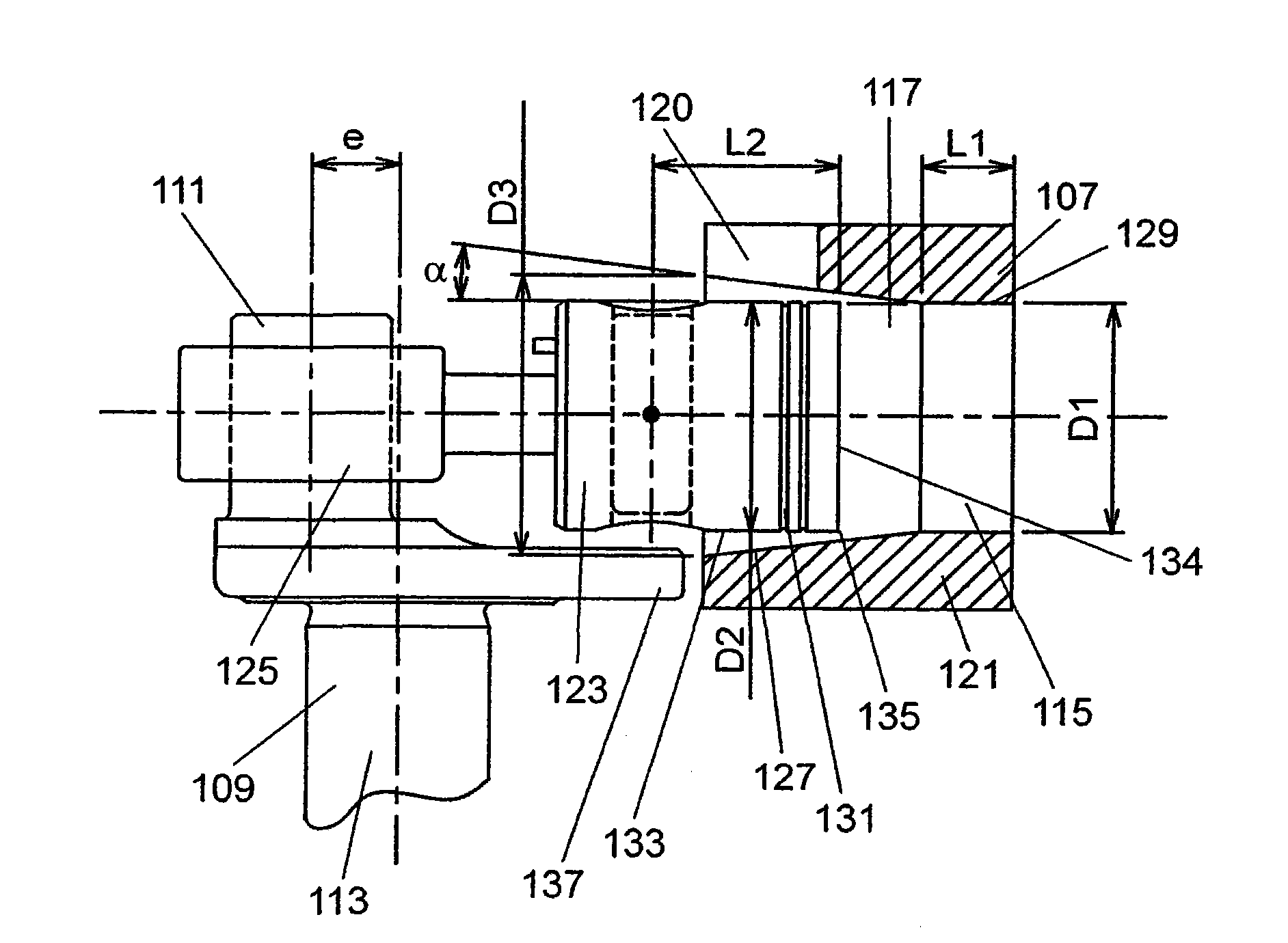

[0067] figure 1 It is a longitudinal sectional view of the hermetic compressor in Embodiment 1 of this invention. figure 2 It is a longitudinal sectional view of main parts of the compression part in this embodiment. image 3 It is a longitudinal sectional view of main parts showing various design elements of the compression part in this embodiment. Figure 4 It is a main part cross-sectional view showing various design elements of the compression part in this embodiment.

[0068] refer to Figure 1 to Figure 4 An electric component 105 including a stator 105 a and a rotor 105 b and a compression element 107 driven by the electric component 105 are housed in the airtight container 103 . Furthermore, lubricating oil 101 is also stored in the bottom of airtight container 103 . The shaft 113 has a main shaft part 109 and an eccentric shaft part 111 formed eccentrically at one end of the main shaft part 109 to move integrally with the main shaft part 109 . The main shaft po...

Embodiment approach 2

[0131] This embodiment differs from Embodiment 1 in the arrangement of the bearing portion 119 and the compression chamber 115 . Other configurations are the same as those in Embodiment 1. Therefore, in this embodiment, configurations different from those in Embodiment 1 will be mainly described.

[0132] Figure 10 It is a longitudinal sectional view of main parts showing various design elements of the compression part in this embodiment. Figure 11 It is a main part cross-sectional view showing various design elements of the compression part in this embodiment.

[0133] Such as Figure 10 , Figure 11 As shown, in this embodiment, the third centerline 142 parallel to the first centerline 141 representing the axis of the bearing portion 119 and the second centerline 143 representing the axis of the compression chamber 115 are arranged so that they intersect each other. A bearing portion 119 and a compression chamber 115 are provided. also, Figure 11 in, due to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com