Gas-liquid mixing device

A gas-liquid mixing and atmospheric technology, applied in mixers, mixing methods, fluid mixers, etc., can solve problems such as vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

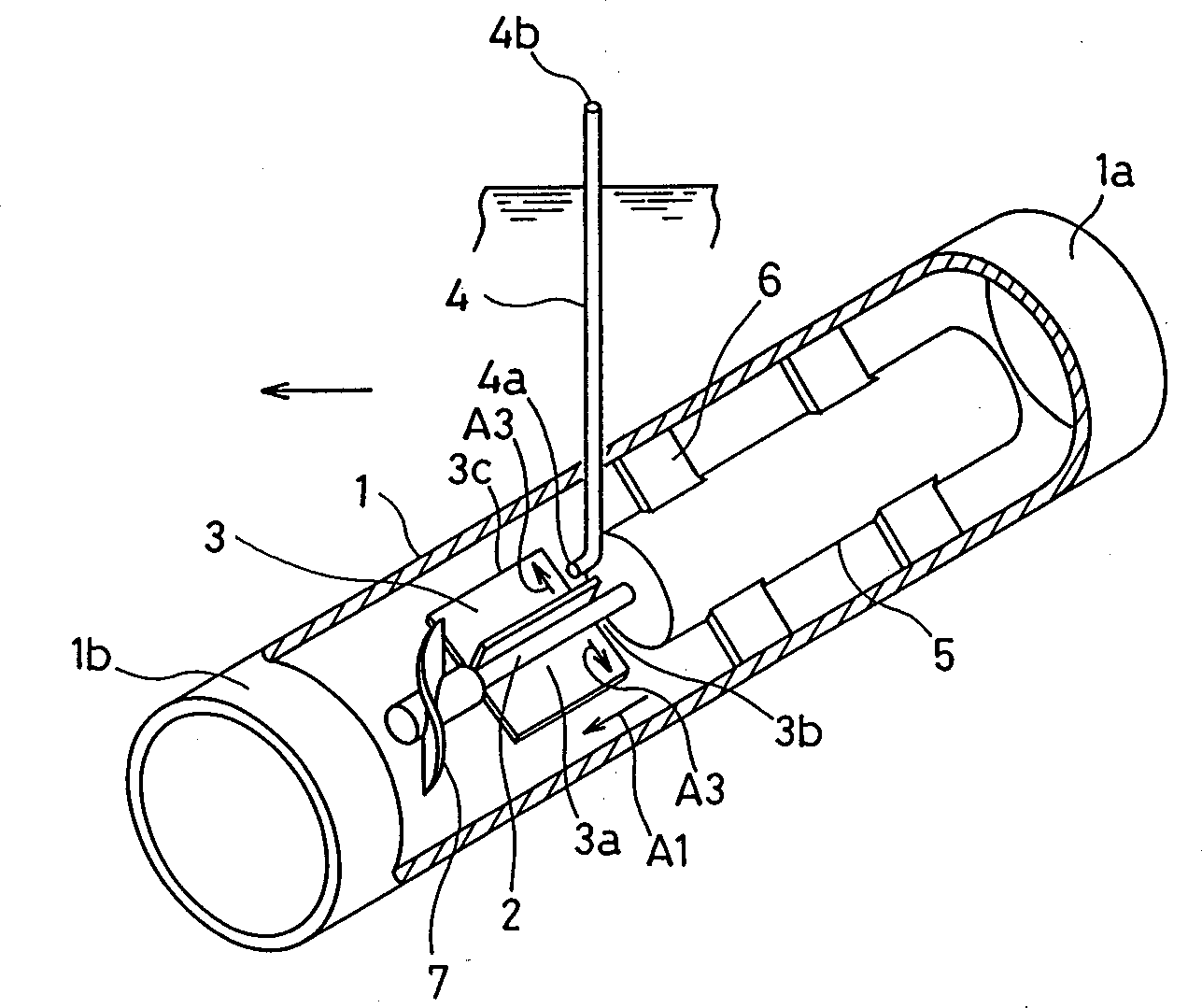

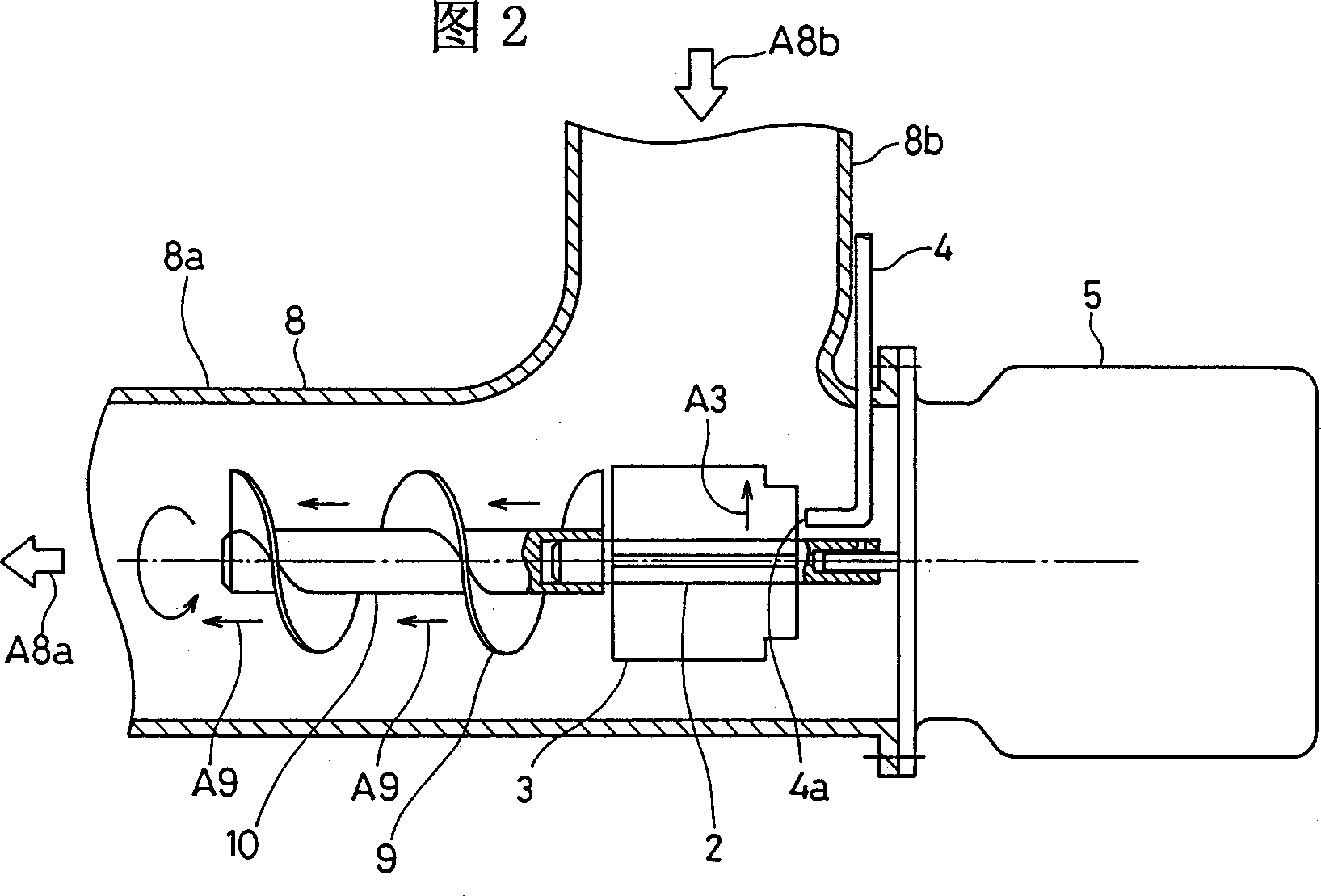

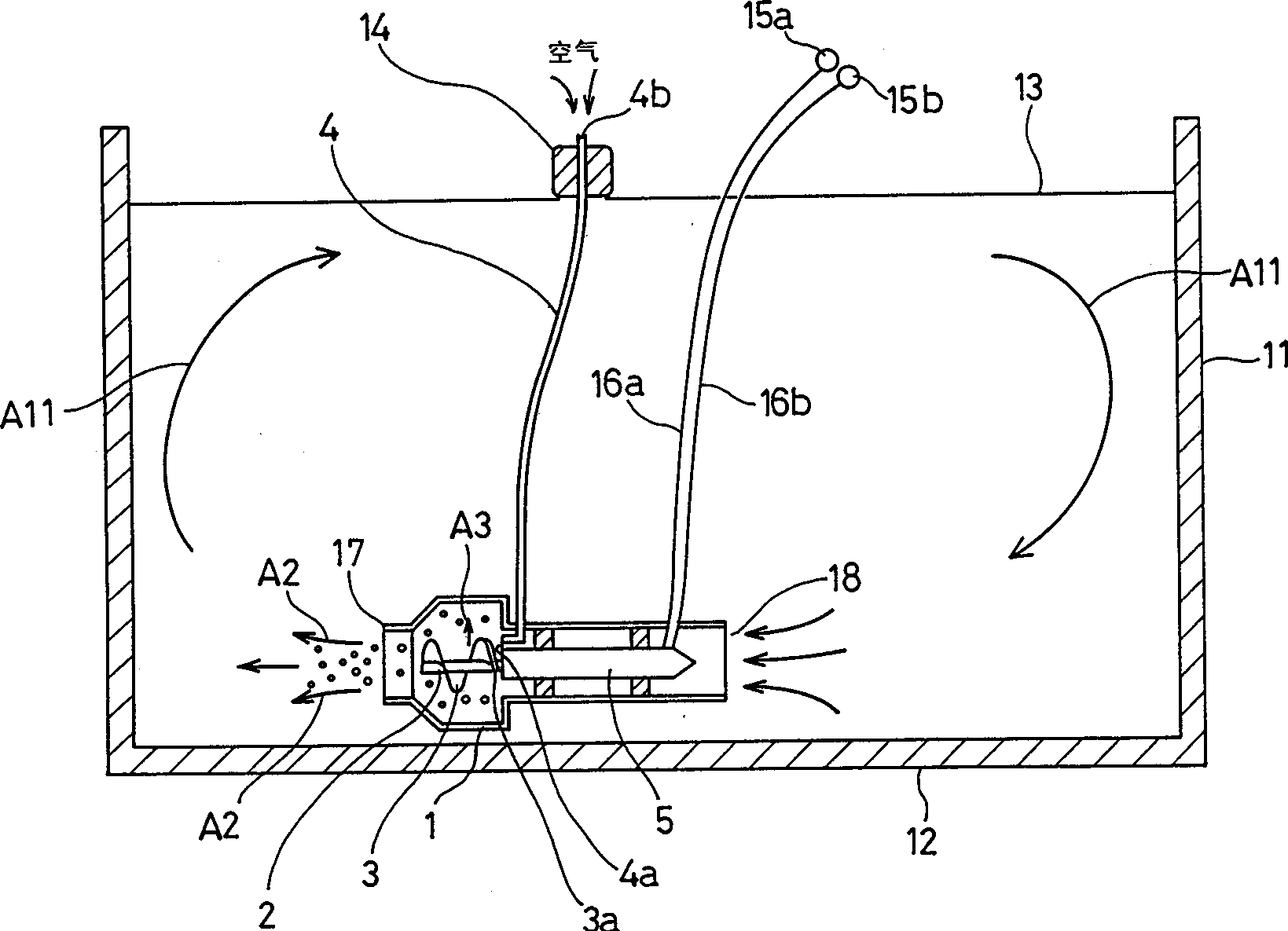

[0021] Such as figure 1 As shown, in a water pipe 1 formed of metal or synthetic resin, etc., a rotating shaft 2 is arranged parallel to its water flow direction A1, and the base end portion 3a of the rotating blade 3 is fixed around the rotating shaft 2, and one end of the air pipe 4 is The opening 4a of the air pipe 4 faces the upstream side 3b near the base end 3a of the rotating blade 3, and the opening 4b at the other end of the air pipe 4 is arranged in the atmosphere outside the water pipe 1.

[0022] The motor 5 is directly connected to the rotating shaft 2 of the above-mentioned rotating blade 3, and it is fixed in the same water pipe 1 by the bracket 6, and the rotating blade 3 is rotated by the motor 5, so that the liquid in the water pipe 1 is rotated. At this time, the liquid generates a flow A3 by centrifugal force from the base end 3a toward the front end 3c of the rotating blade 3, and the liquid near the front end 3c is pressurized to a positive pressure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com