Cooling apparatus of scrapers

A cooling device and mechanical technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of aggravated engine overheating, poor cooling effect, large wind energy loss, etc., to reduce the working pressure of the fan and ensure the air cooling effect. , the effect of reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

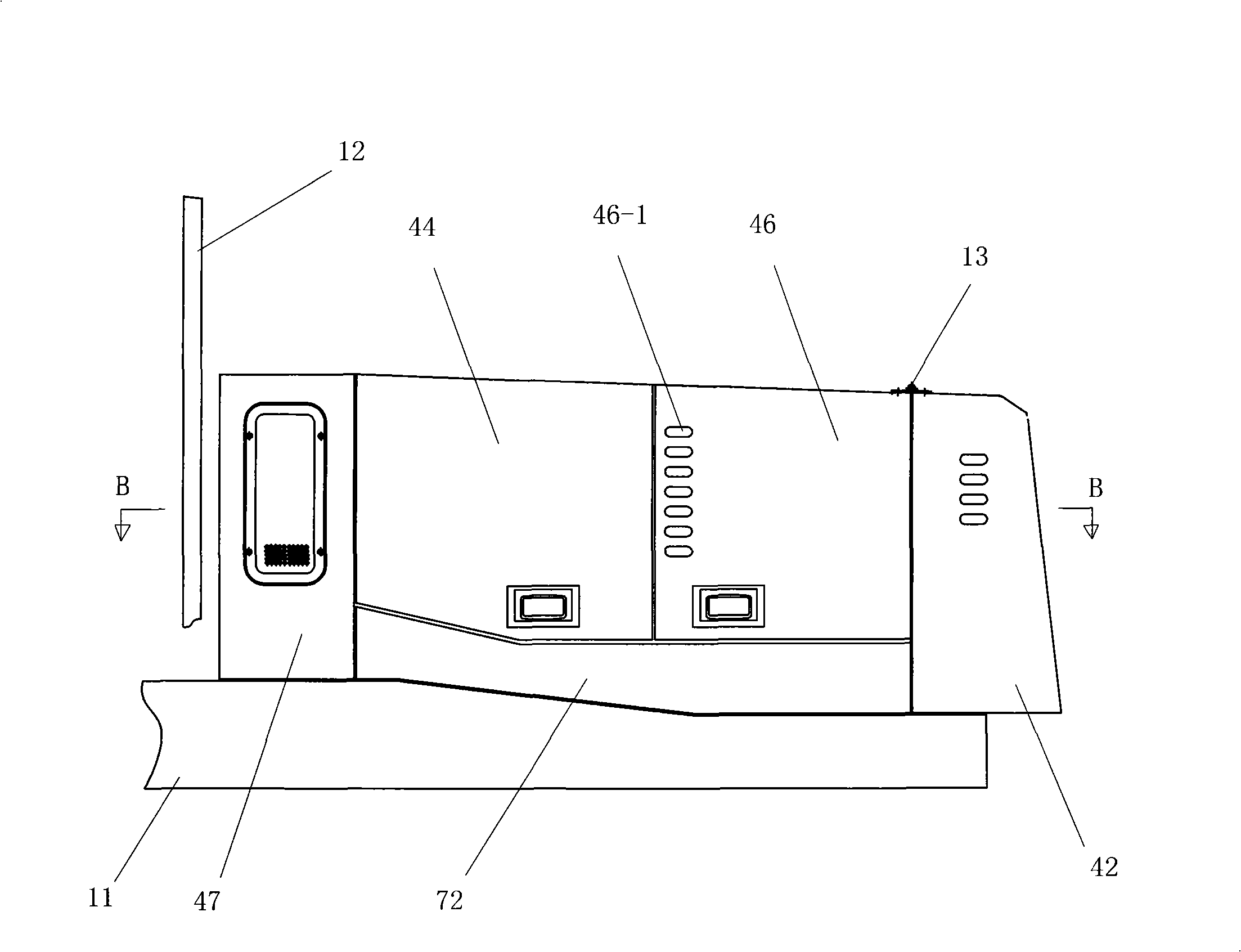

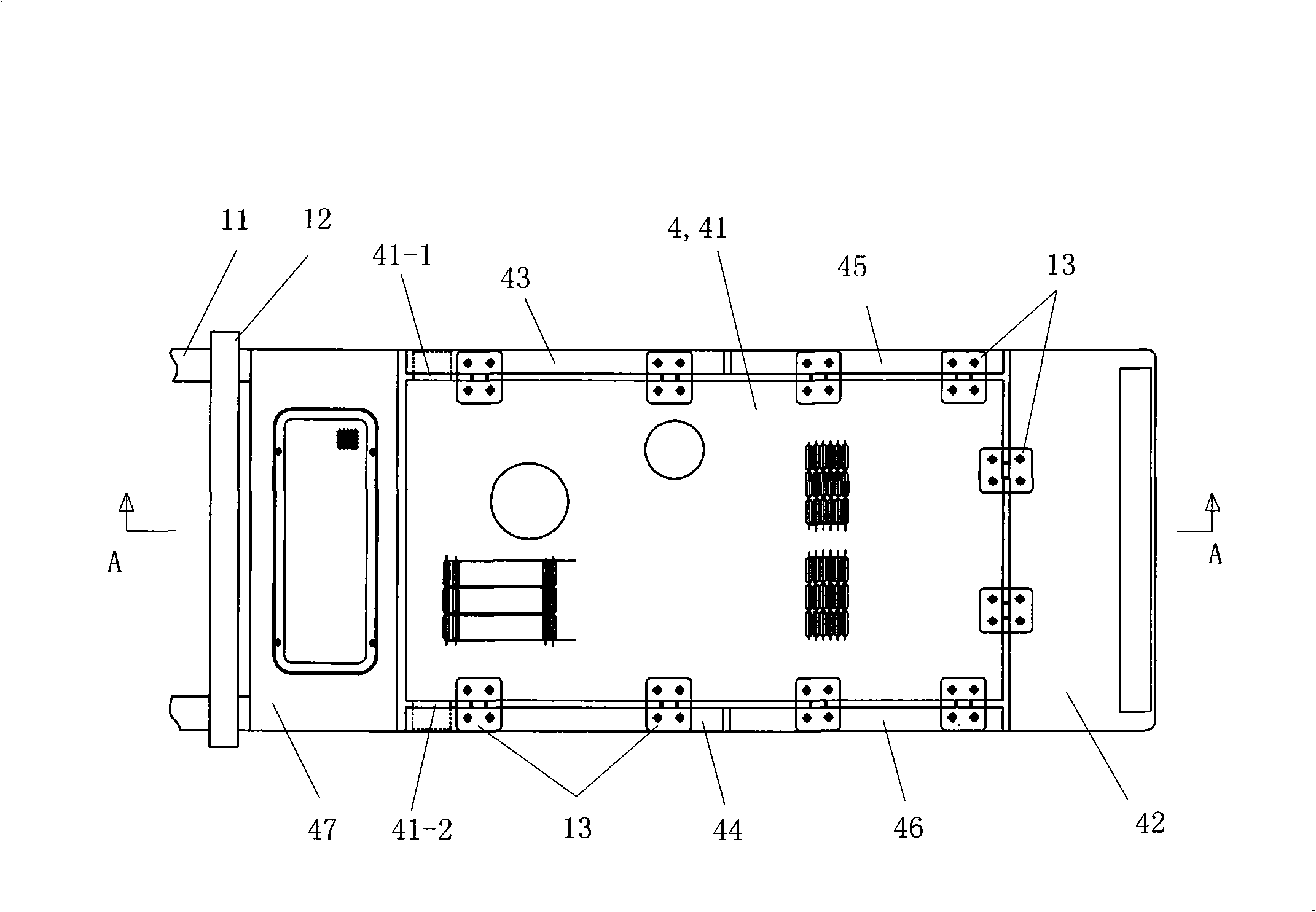

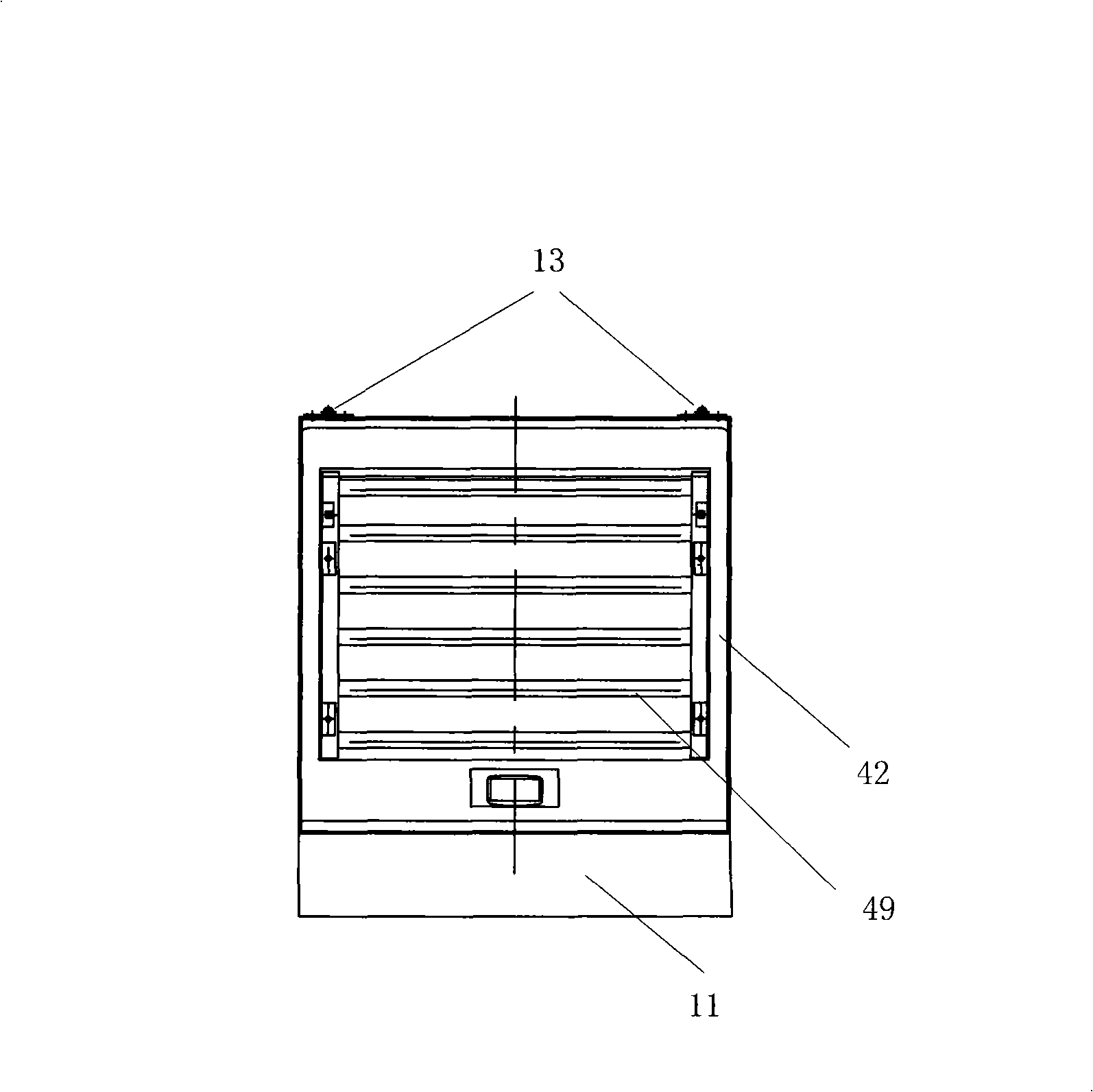

[0040] See Figure 1 to Figure 4 , the cooling device of the shoveling machine of the present embodiment is a cooling device of a loader or a grader, including a vehicle frame 11, a mounting frame 2, a heat shield 3, an outer cover 4, a water radiator 51, and an intercooler 52 , oil radiator 53 and cooling fan 54. The cooling fan 54 is a fan that sucks air from the back to the front during work.

[0041] still see Figure 1 to Figure 4 , the water radiator 51, the intercooler 52, the oil radiator 53, the cooling fan 54 and the heat shield 3 are located in the outer cover 2; Radiator 53 and cooling fan 54 are fixed on the mounting frame 2; Cooling fan 54 is fixed on the vehicle frame 11 by corresponding elastic support; Cooling fan 54, water radiator 51, intercooler 52 and oil radiator 53 The direction is set according to the front and rear three rows, the cooling fan 54 is located in the rear row, and is arranged at the tail of the vehicle frame 11; the water radiator 51 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com