Control method and device of separation and reunion type water pump for engine

A control method and engine water temperature technology, which is applied to the control device of the cooling device, engine cooling, engine components, etc., can solve problems such as troublesome algorithms, high cost, and inability to adjust the flow rate, so as to ensure fast warm-up and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

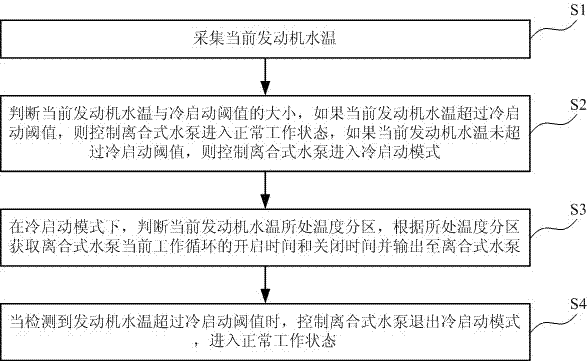

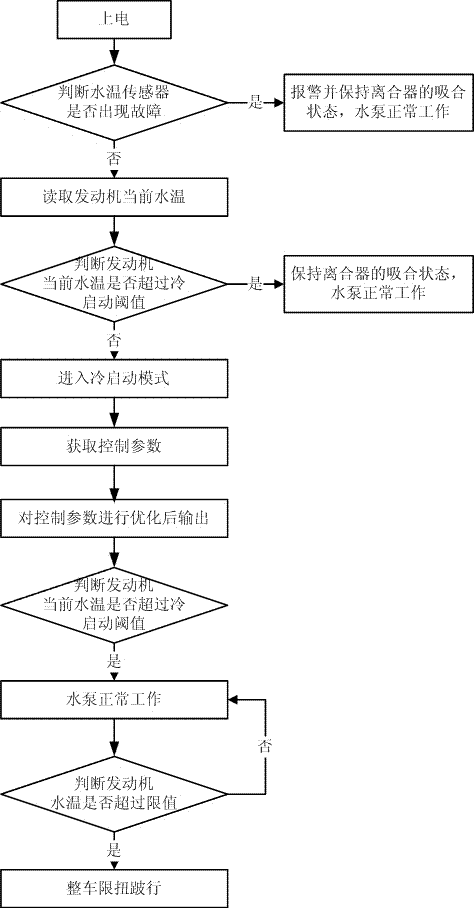

[0060] Please refer to figure 1 As shown, Embodiment 1 of the present invention provides a control method for a clutch-type water pump for an engine, including:

[0061] Step S1, collecting the current engine water temperature;

[0062] Step S2: Determine the current engine water temperature and the cold start threshold. If the current engine water temperature exceeds the cold start threshold, control the clutch water pump to enter the normal working state. If the current engine water temperature does not exceed the cold start threshold, control the clutch water pump to enter the cold start state. start mode;

[0063] Step S3, in the cold start mode, determine the temperature zone where the current engine water temperature is located, and obtain the opening time and closing time of the current working cycle of the clutch water pump according to the temperature zone, and output it to the clutch water pump;

[0064] Step S4, when it is detected that the engine water temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com