A kind of method for preparing methyl formate

A technology of methyl formate and methanol, which is applied in the field of preparing methyl formate, can solve the problems of synthetic methyl formate impurity sensitivity, strict requirements on raw material purity, complicated process route, etc., and achieve environment-friendly production process safety, product separation investment and The effect of low energy consumption and high process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Production of methyl formate reaction process:

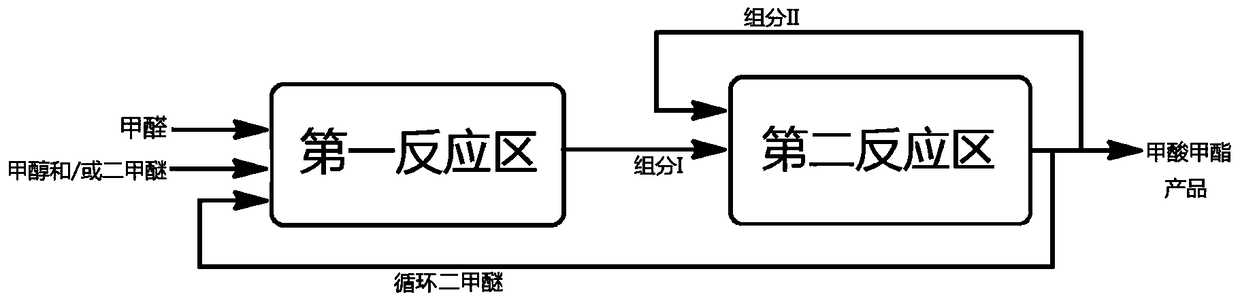

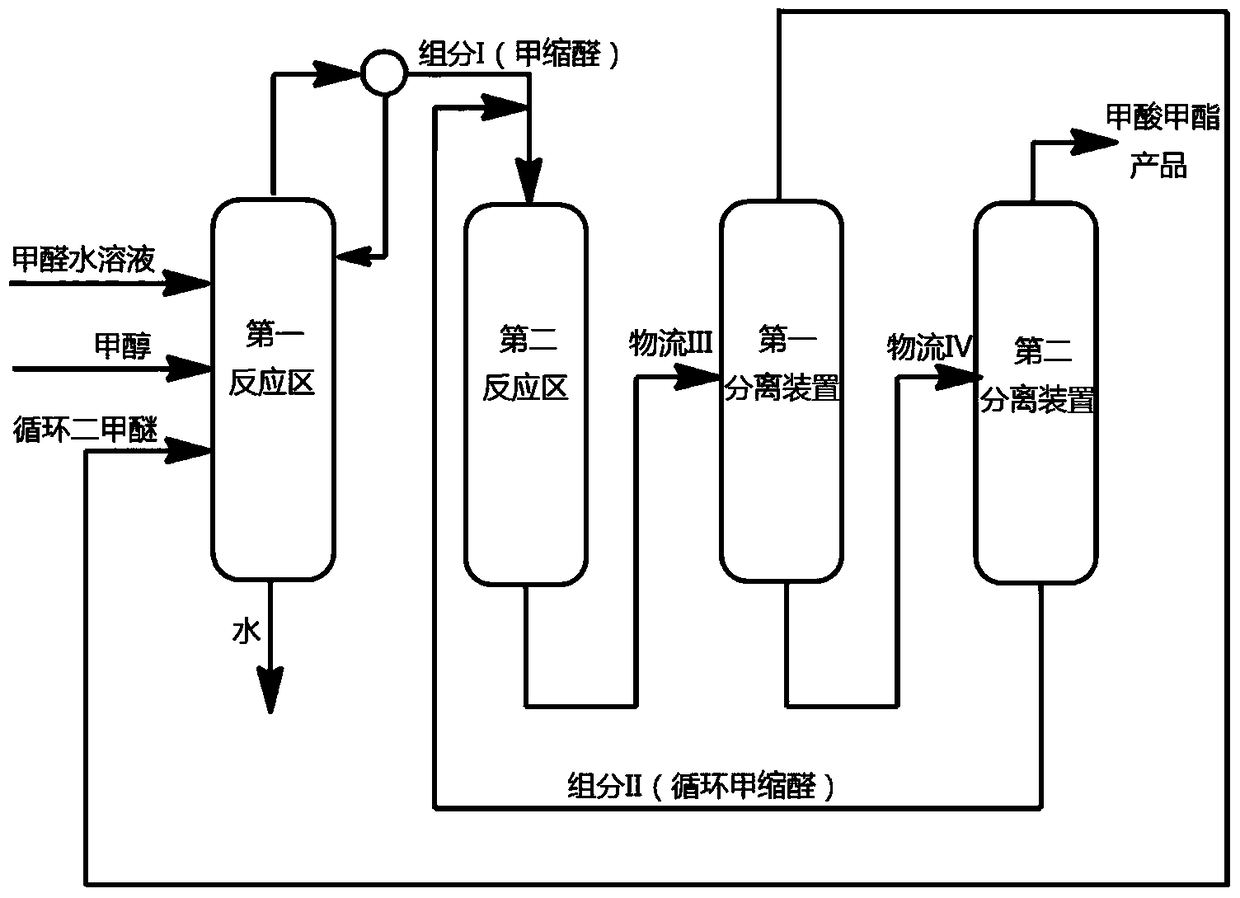

[0058] As a typical scheme, the reaction process flow of the method for the production of methyl formate of the present application is as follows figure 2 As shown, wherein, the first reaction zone uses a catalytic rectification tower to carry out the process of preparing methylal from the condensation reaction of formaldehyde, methanol, and dimethyl ether; the second reaction zone uses a fixed-bed reactor to carry out the disproportionation reaction of methylal; The first-stage separation device is used for the separation of dimethyl ether in the product of the disproportionation reaction of methylal; the second-stage separation device is used for the separation of methyl formate, the product of the disproportionation reaction of methylal, from unreacted raw materials.

[0059] Specifically, the raw materials include: formaldehyde solution, methanol, and recycled dimethyl ether separated from the product. The above thre...

Embodiment 2~6

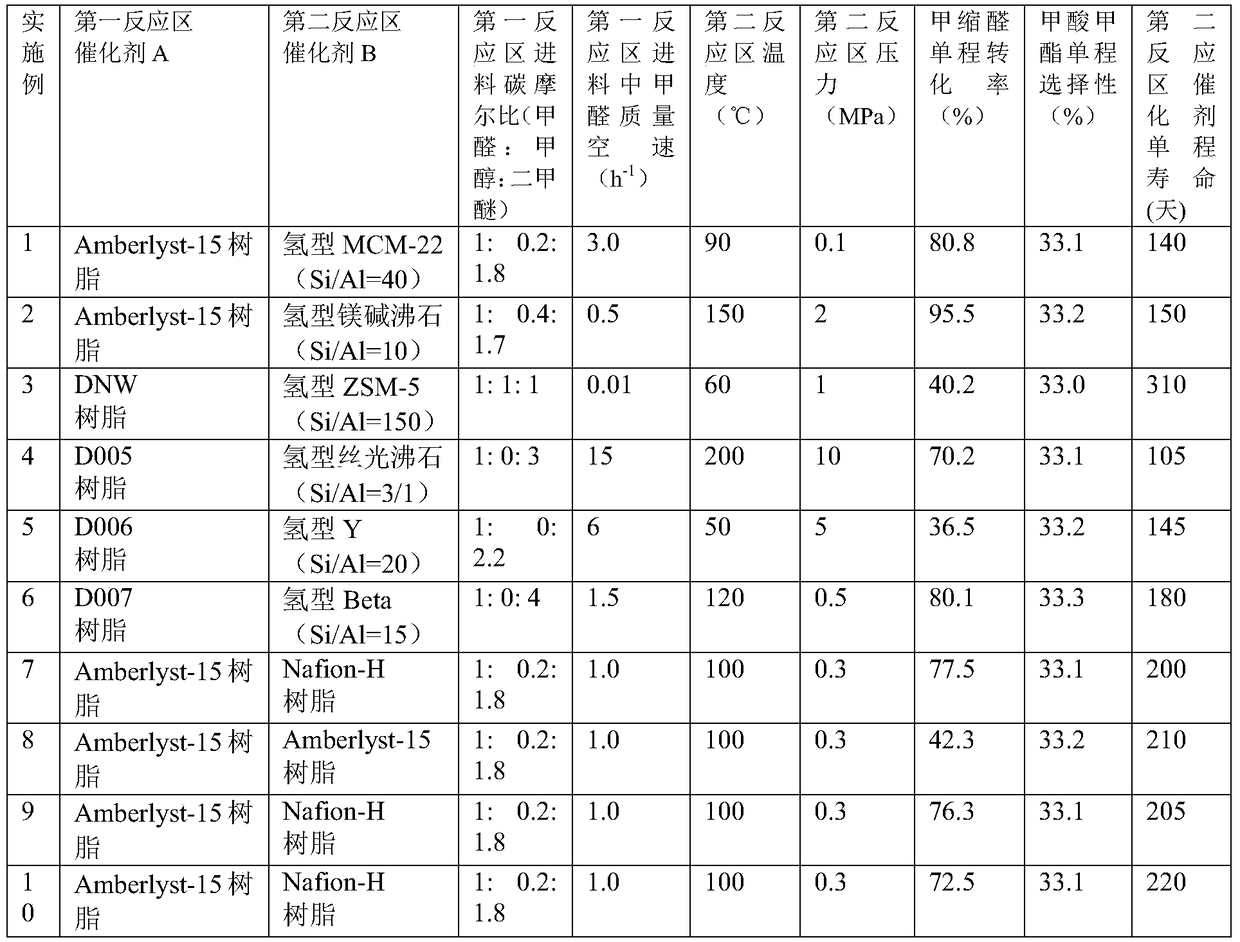

[0066] Catalyst A in the first reaction zone, catalyst B in the second reaction zone, feed ratio in the first zone, mass space velocity of formaldehyde in the feed to the first zone, temperature in the second reaction zone, and pressure in the second reaction zone are shown in Table 1. , other operation steps are all identical with embodiment 1, and its reaction result is shown in table 1.

Embodiment 7~8

[0068] Catalyst B in the second reaction zone is shown in Table 1. Weigh 200g of 20-40 mesh catalyst, put it into a stainless steel reaction tube with an inner diameter of 30mm, activate it with nitrogen at normal pressure and 100°C for 1 hour, and then carry out the reaction. Catalyst A in the first reaction zone, the ratio of feed to the first zone, the mass space velocity of formaldehyde in the feed to the first zone, the temperature in the second reaction zone, and the pressure in the second reaction zone are respectively shown in Table 1, and other operating steps are all in accordance with the implementation Example 1 is the same, and its reaction result is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com