Method and device for thermally activating packaging sheaths

A packaging sleeve, heat activated technology, used in packaging, transport packaging, transportation and packaging, etc., can solve the problems of manufacturing and maintenance-intensive expensive, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

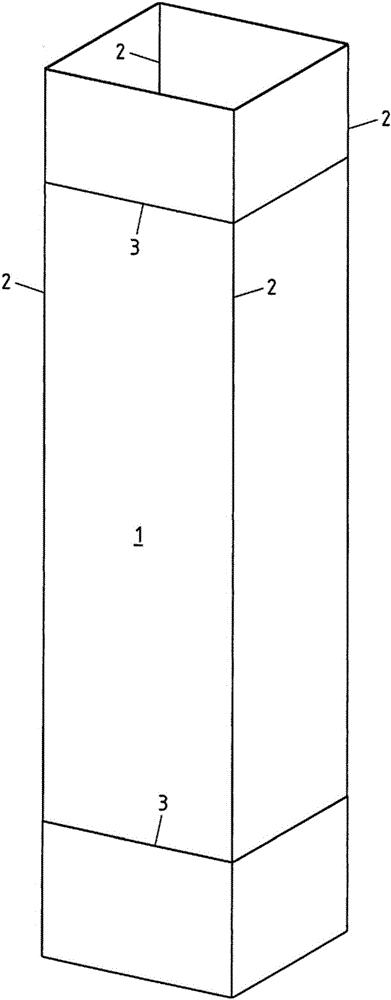

[0025] figure 1 A tubular packaging sleeve 1 is shown as packaging material for future beverage packaging. A packing sleeve 1 of this type is produced with a longitudinal seam from a cut, which is not shown. It can be in any position, for example in the central area or on one of the edges 2 . Furthermore, the crease line 3 can be considered to be used to fold the base and gable area (head area) of the future package.

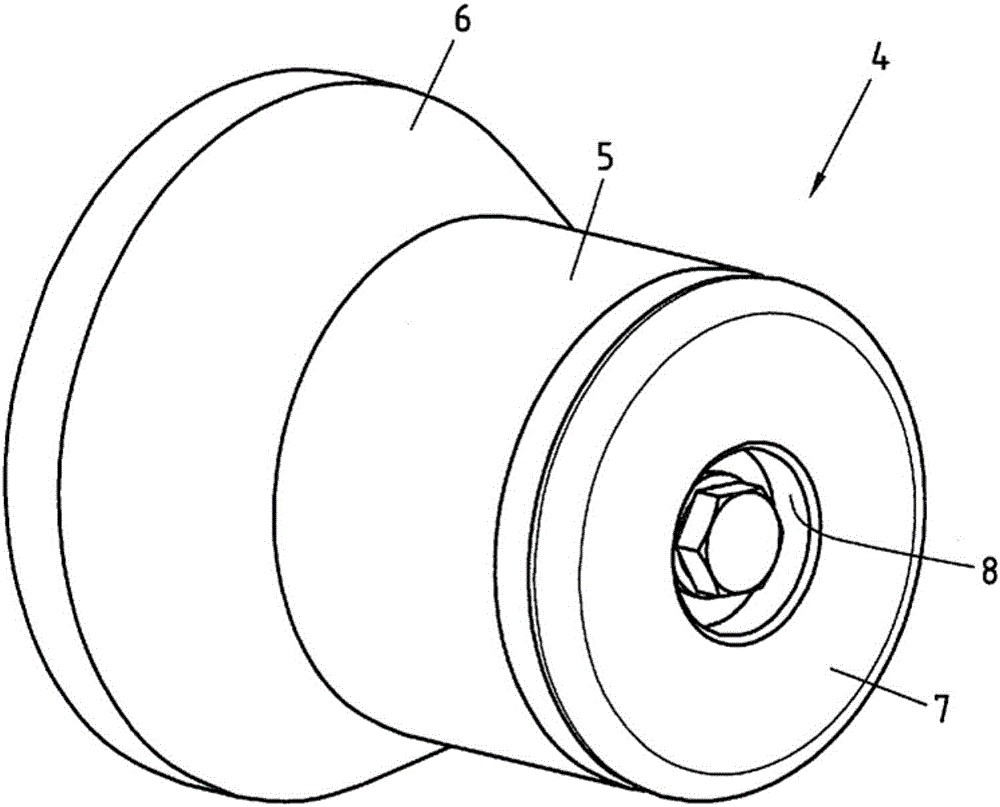

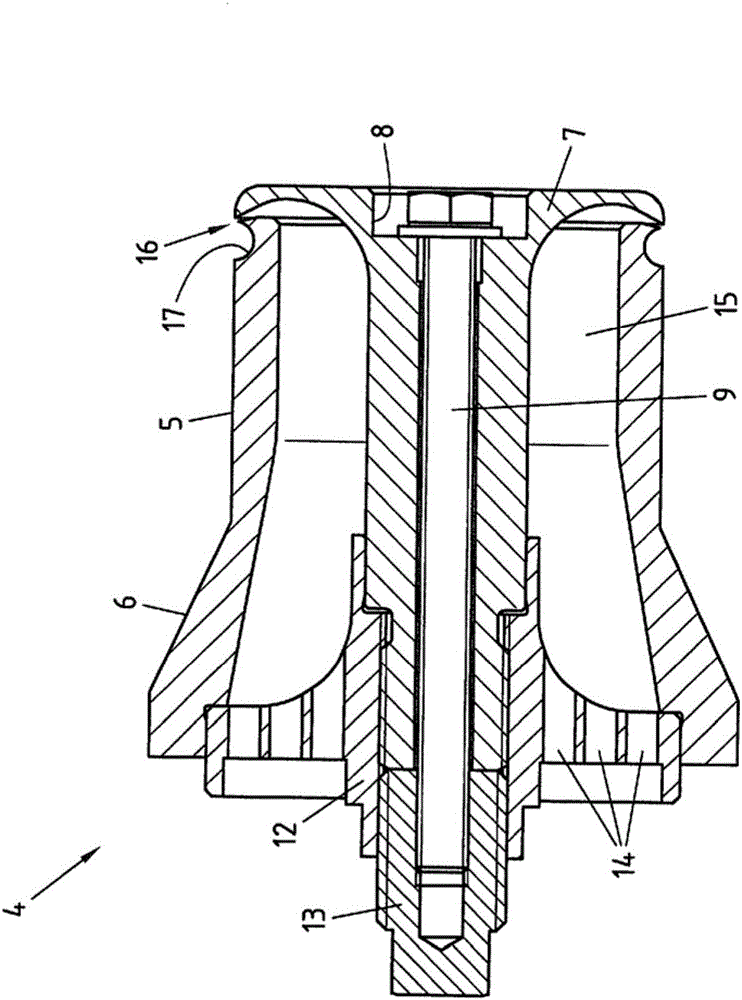

[0026] figure 2 Shown is a nozzle element 4 ideally used for the device according to the invention, which firstly and substantially comprises a hollow cylindrical outer part 5, and a conical dispensing part 6 and an inner part 7 arranged in the outer part 5, In this case the inner part 7 almost completely seals off the open side of the hollow cylindrical outer part 5 . On the front face of the inner part 7 , grooves 8 can be considered to accommodate the heads of screws 9 attaching the outer part 5 to the inner part 7 .

[0027] To provide a better view, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com