Method for preparing methyl formate and co-producing dimethyl ether

A technology of methyl formate and dimethyl ether, which is applied in the field of preparation of methyl formate, can solve the problems of strict raw material purity, difficulty in forming scale effect, pollution, etc., and achieve high market economic value, not easy to oxidize and deactivate, atomic High economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

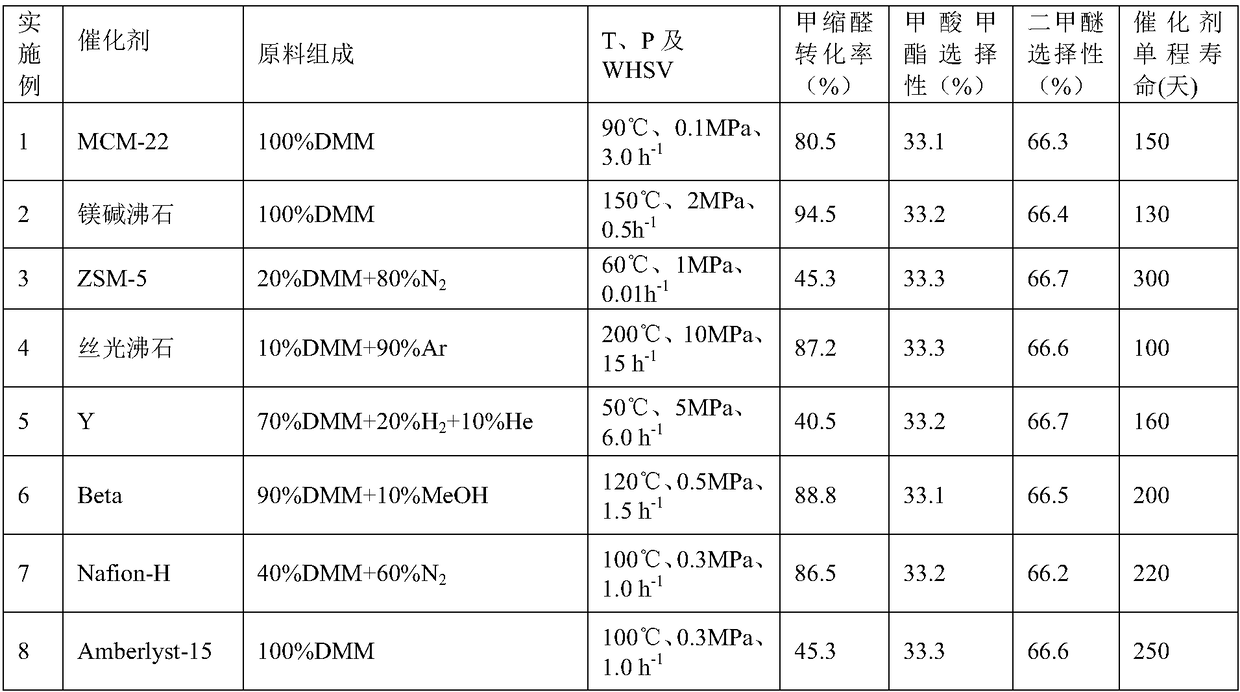

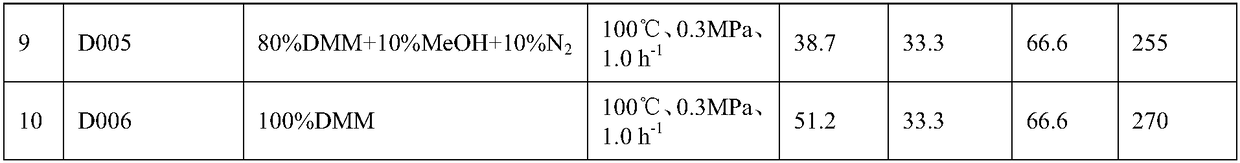

Embodiment 1

[0036] 50g of hydrogen-type MCM-22 molecular sieve catalyst with a silicon-aluminum ratio (Si:Al)=40:1 was calcined at 550°C for 5 hours in the air atmosphere of a muffle furnace, and a part of the powder sample was taken to be pressed into tablets and crushed into 20-40 mesh , for activity testing. Weigh 10 g of the hydrogen-type MCM-22 molecular sieve catalyst sample, put it into a stainless steel reaction tube with an inner diameter of 8.5 mm, activate it with nitrogen at normal pressure and 550 ° C for 4 hours, then drop it to the reaction temperature (T) = 90 ° C, pass The molar composition of the raw material is 100% methylal, reaction pressure (P)=0.1MPa, methylal mass space velocity (WHSV)=3h -1 , using gas chromatography to analyze the product. After the reaction was stable, the conversion rate of methylal and the selectivity of the product were calculated. The reaction results are shown in Table 1.

Embodiment 2

[0038] The catalyst in Example 1 was replaced with a hydrogen-type ferrierite molecular sieve with a silicon-aluminum ratio (Si:Al)=10:1, except that the reaction temperature was changed to T=150°C, the reaction pressure was changed to P=2MPa, and the methylal Change mass airspeed to WHSV=0.5h -1 , all the other experimental procedures are consistent with Example 1, and the reaction results are shown in Table 1.

Embodiment 3

[0040] The catalyst in Example 1 is replaced by a hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio (Si:Al)=150:1, except that the reaction temperature is changed to T=60° C., and the molar composition of the raw materials is changed to 20% methylal and 80% nitrogen mixture, the reaction pressure is changed to P=1MPa, the mass space velocity of methylal is changed to WHSV=0.01h -1 , all the other experimental procedures are consistent with Example 1, and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com